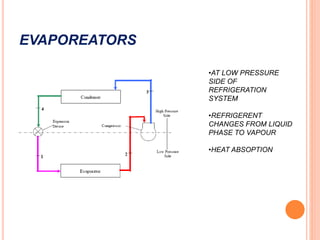

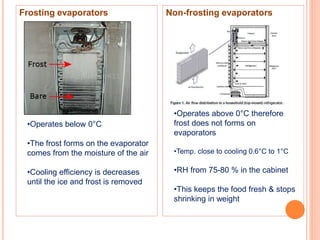

Evaporators are components in refrigeration systems that absorb heat from the surrounding environment. They operate at the low pressure side where the refrigerant changes from a liquid to a vapor phase. The heat transfer capacity of an evaporator depends on factors like the heat transfer coefficient, surface area, temperature difference, and refrigerant velocity. There are several types of evaporators classified by their construction, refrigerant feed method, heat transfer mode, and operating conditions like frosting, non-frosting, and defrosting. Evaporators are widely used in industries like food processing, beverages, chemicals, and more to absorb heat for cooling applications.