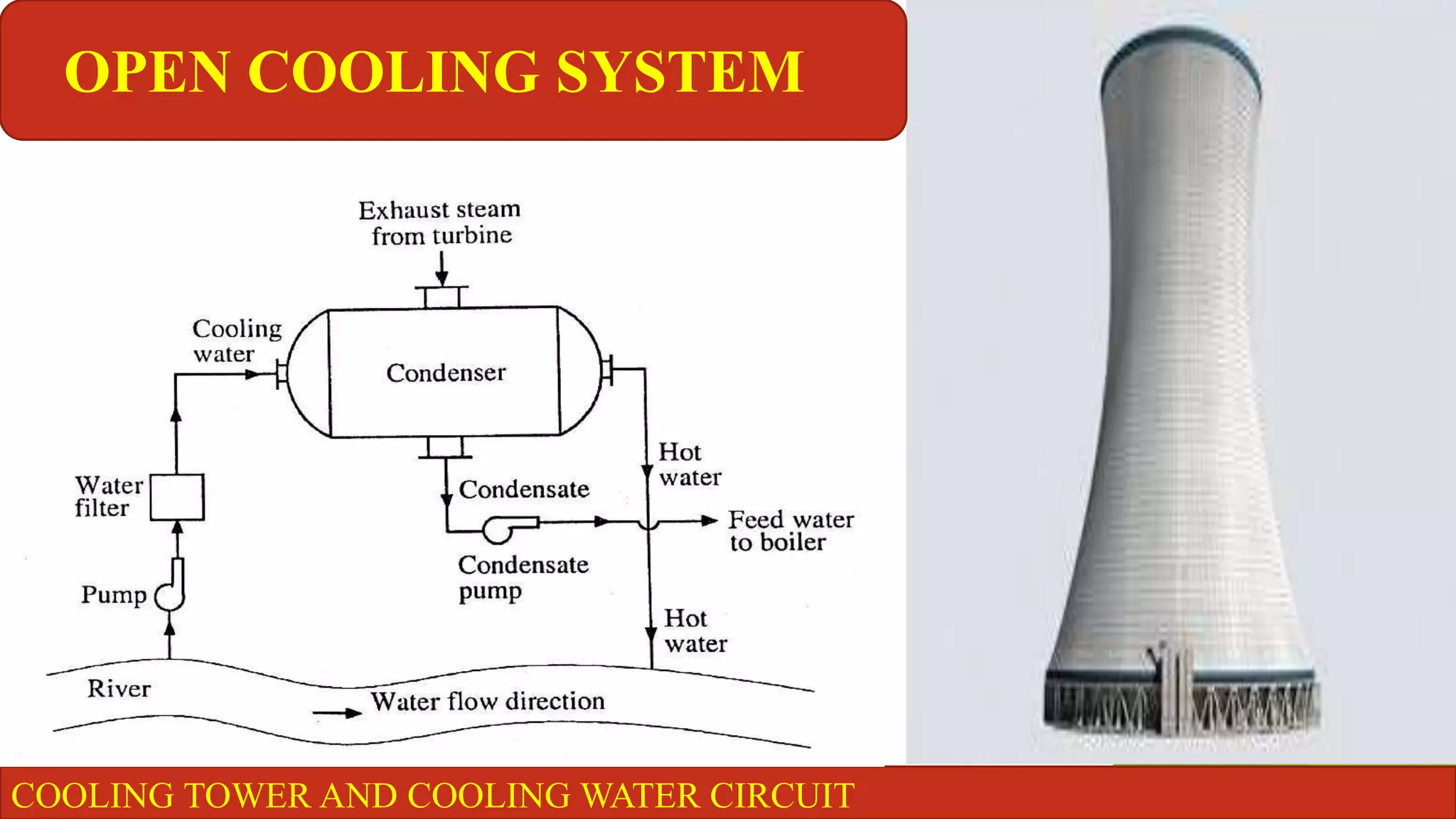

Shakil Hossain presented on cooling tower and cooling water circuits. The presentation covered different types of cooling systems including open, closed, and mixed systems. It described the components and types of cooling towers such as natural draught, forced draught, and induced draught towers. The presentation also discussed liquid cooling systems including liquid-to-liquid, closed-loop dry, open-loop evaporative, closed-loop evaporative, and chilled water systems. The key advantages and disadvantages of natural draught, forced draught, and induced draught cooling towers were highlighted.