1. The document discusses a hydraulically driven engine cooling fan system that is becoming more common to reduce noise in construction equipment.

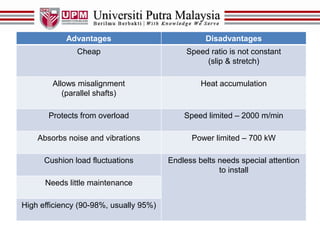

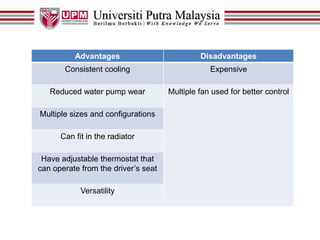

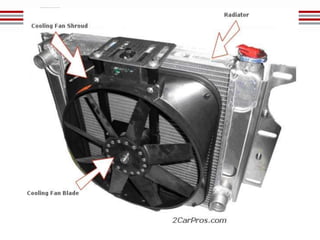

2. It describes the functions of cooling fans to circulate air through the radiator and release engine heat, and compares mechanical and electrical fan types.

3. The document outlines factors to consider when selecting a cooling fan, including capacity, airstream properties, physical limitations, noise levels, and safety accessories. It then discusses how thermal clutch fans work to efficiently cool engines.