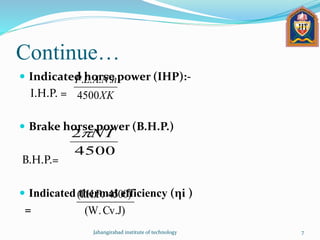

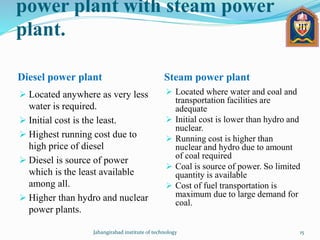

The document discusses the components, operation, and site selection considerations of diesel power plants. It describes how diesel engines convert fuel into mechanical energy to generate electricity. Key components include the engine, air intake and exhaust systems, fuel system, cooling system, and lubrication system. Performance is determined by factors like indicated and brake horsepower. Ideal sites are near load centers with available water, fuel, and transportation, while avoiding populated areas. Diesel plants have lower initial costs but higher operating expenses than steam plants.