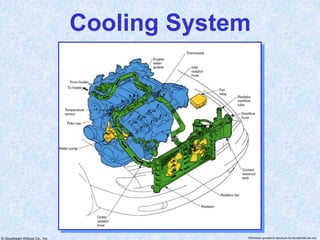

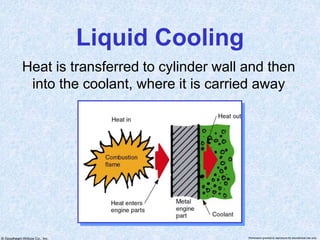

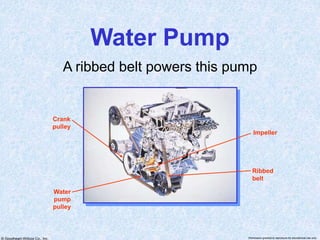

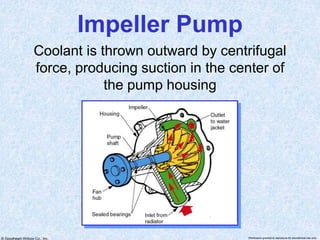

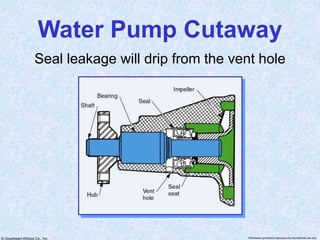

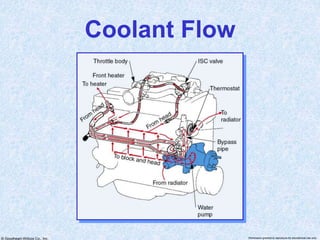

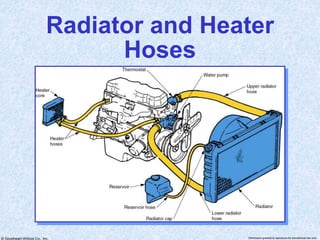

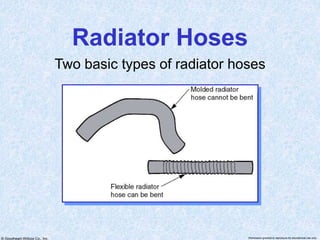

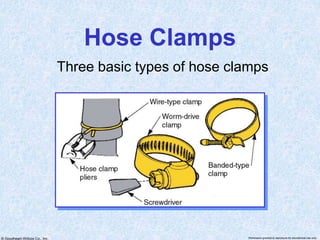

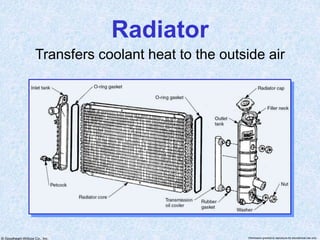

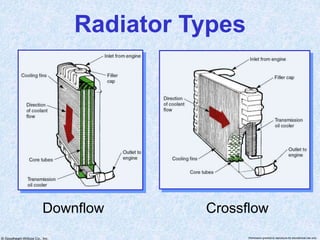

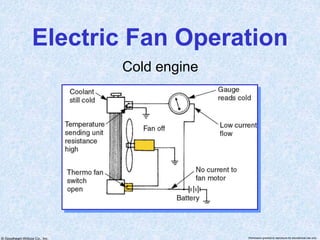

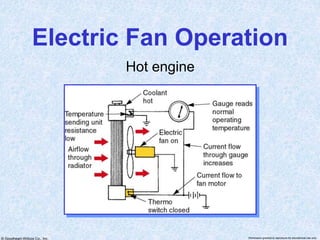

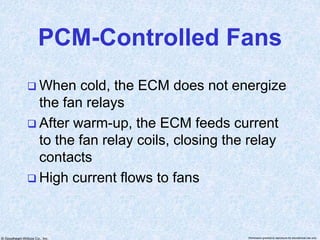

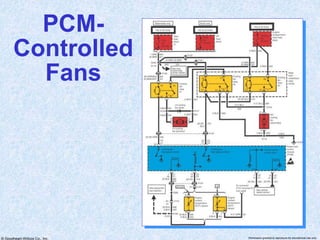

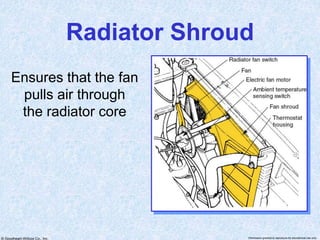

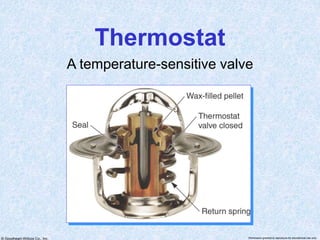

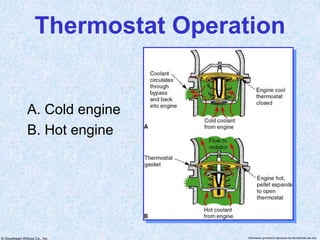

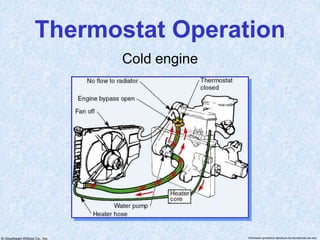

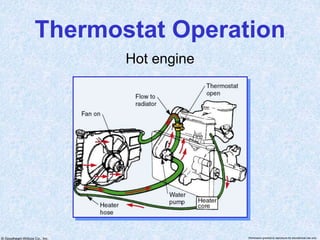

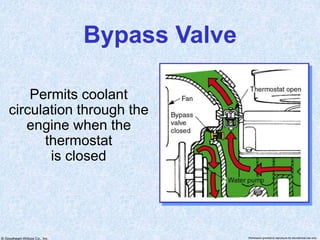

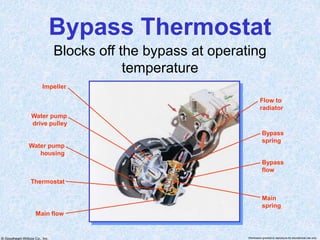

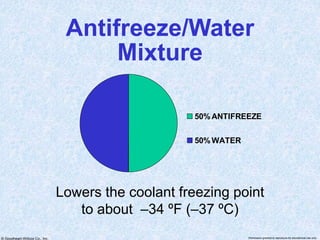

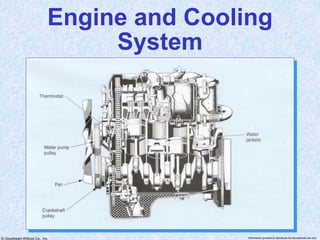

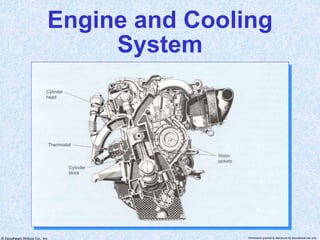

The document discusses the components and functions of a basic automotive cooling system. It describes how the system works to remove excess engine heat and maintain proper operating temperature. Key components discussed include the water pump, radiator, hoses, thermostat, fans, and antifreeze. The cooling system circulates coolant through the engine and radiator to efficiently cool the engine during operation.