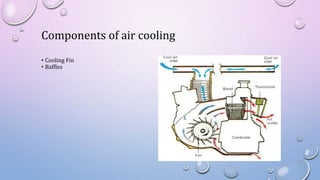

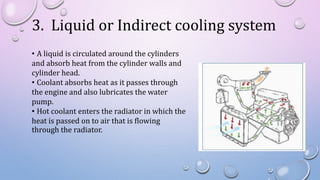

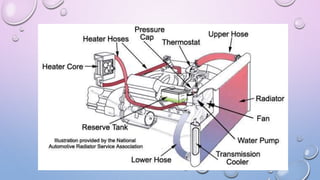

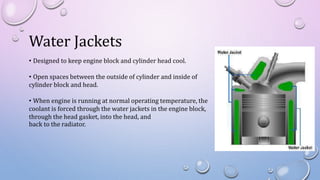

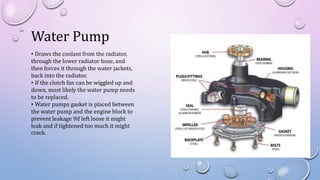

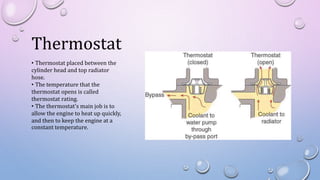

The document discusses the importance of automobile cooling systems in maintaining optimal engine temperature, particularly under high loads and speeds. It explains various types of cooling systems, including air, oil, and liquid cooling, along with their advantages, disadvantages, and components. Additionally, it highlights the role of coolants and antifreezers in protecting engine parts and enhancing performance.