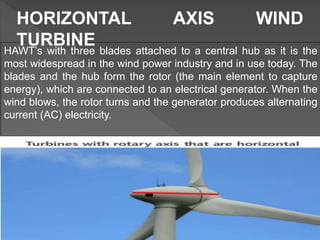

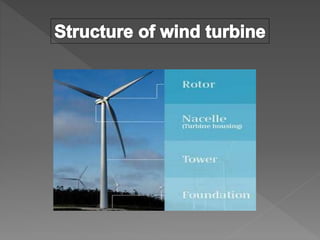

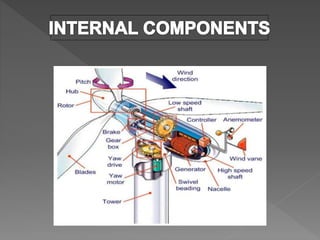

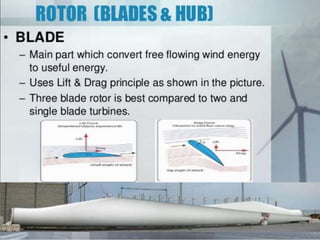

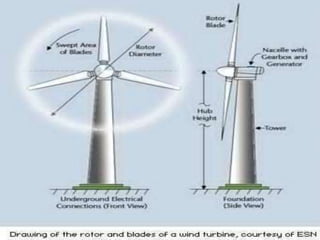

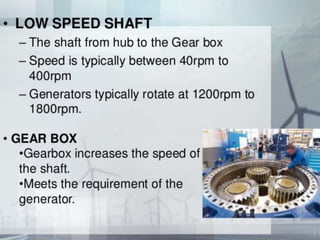

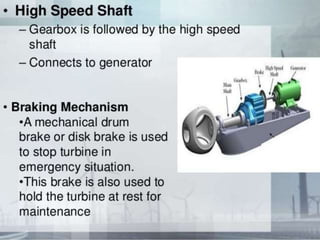

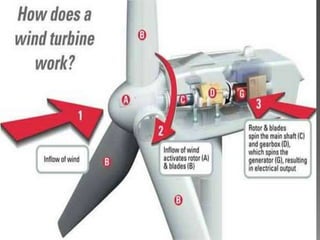

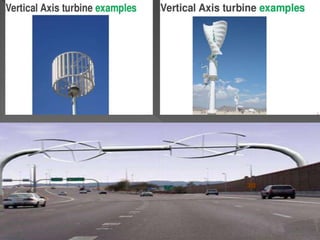

Renewable energy can be obtained from natural flows of energy like sunlight and wind. Wind energy is extracted from kinetic wind power using wind turbines. Most common wind turbines are horizontal axis wind turbines (HAWT) that have three blades attached to a central hub to capture the energy of the wind and power an electrical generator. HAWTs are the most widespread in use today. Vertical axis wind turbines (VAWT) also exist but are less common as they do not take advantage of higher wind speeds at higher elevations like HAWTs.