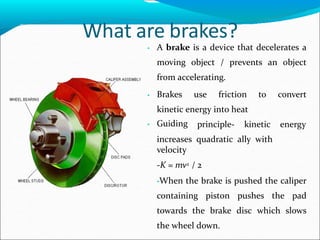

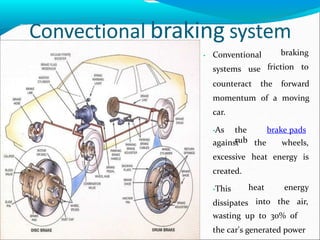

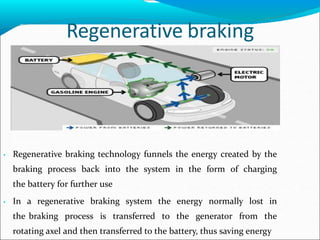

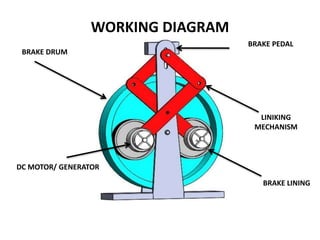

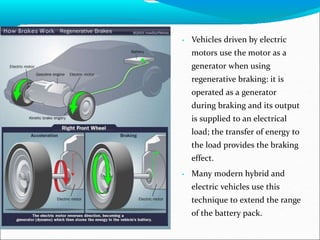

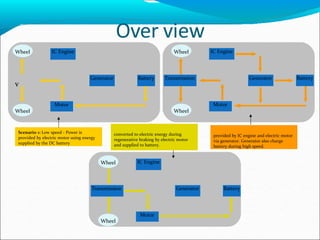

This document proposes a regenerative braking system for electric vehicles. It works by using electric motors connected to brake linings as generators to convert kinetic energy from braking into electricity. When the brakes are applied, the linings touch the rotating brake drum and spin the motors, generating electricity. This captured energy can be stored in the vehicle's batteries and used to extend its driving range between charges. Regenerative braking provides benefits like reduced pollution, increased engine efficiency from recovered energy, less wear on brake components, and savings from not wasting as much kinetic energy as heat. However, conventional friction brakes are still required for backup and stopping ability at low speeds when regeneration is less effective.