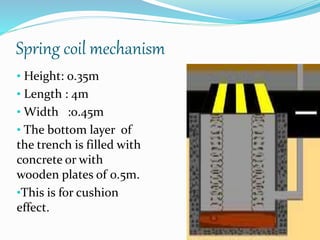

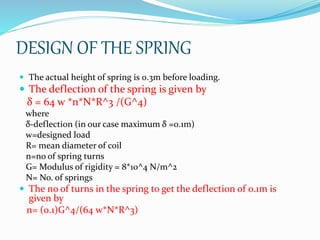

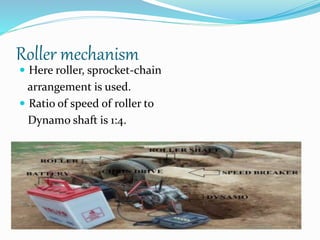

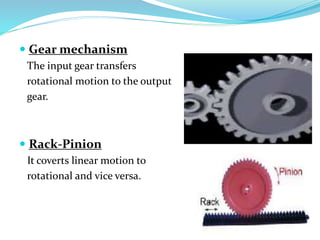

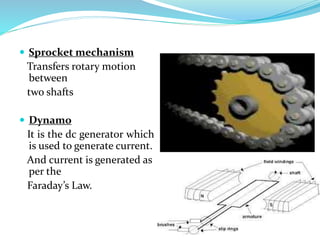

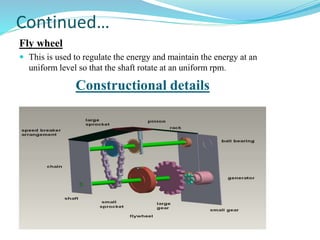

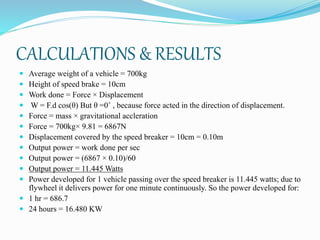

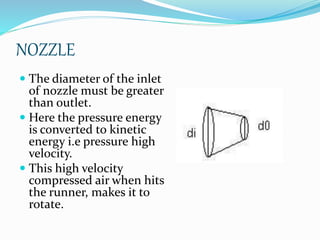

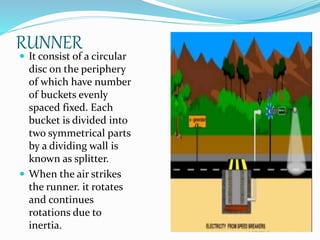

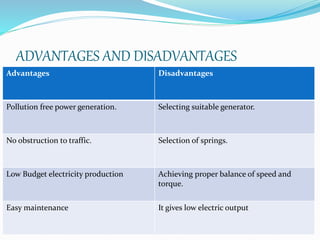

The document discusses various mechanisms for generating electricity from speed breakers, utilizing the kinetic energy of vehicles as they pass over them. It explores different systems like the spring coil, roller, and rack-pinion mechanisms, highlighting their construction, working principles, and potential energy output. The approach aims to harness energy from non-conventional sources, addressing the depletion of traditional energy resources.