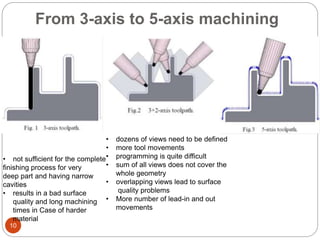

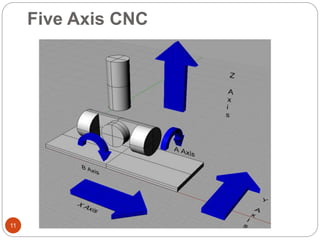

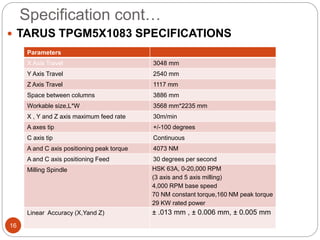

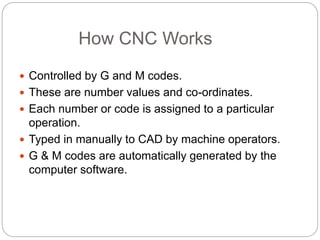

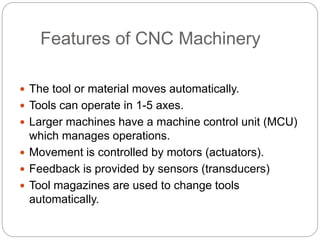

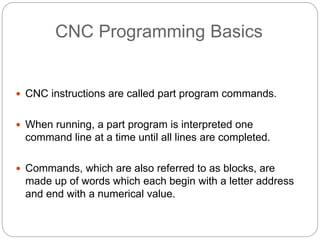

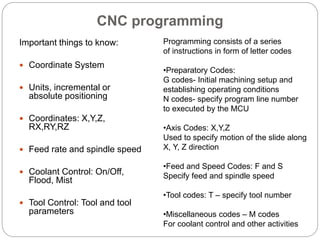

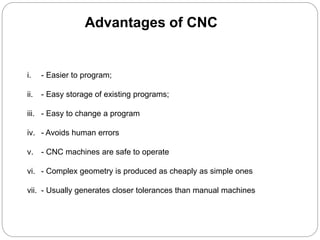

This document provides an introduction to computer numerical control (CNC) machines. It discusses that CNC machines operate using programmed codes rather than manual control. The document outlines various CNC operations like milling and drilling. It describes the advantages of CNC machines as being able to operate continuously with high accuracy, batch production, and ability to update software. Five-axis CNC machines are discussed as able to machine complex shapes in a single setup. Specifications are provided for a sample five-axis CNC machine including its travel distances and spindle capabilities.