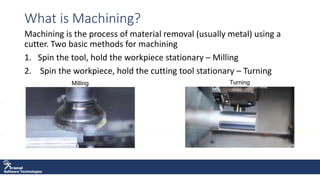

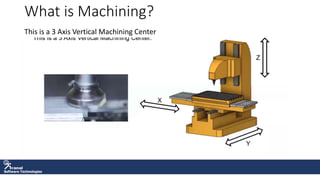

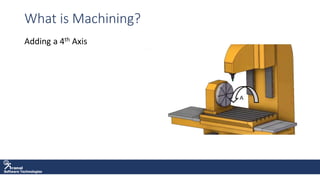

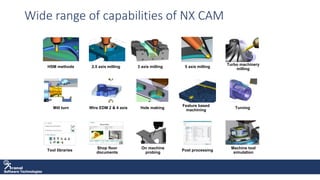

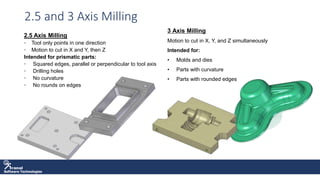

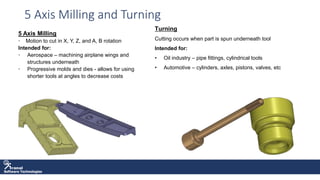

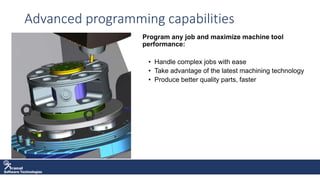

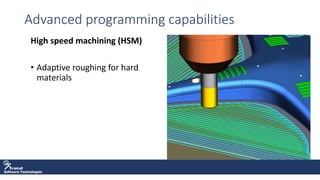

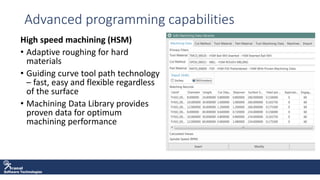

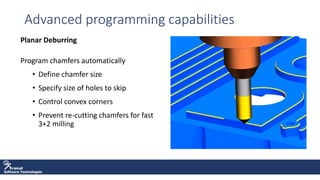

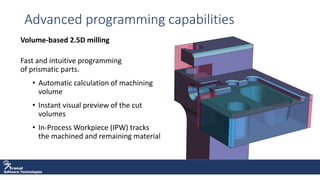

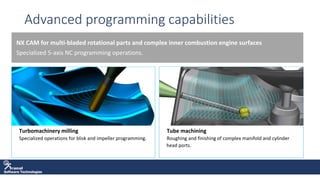

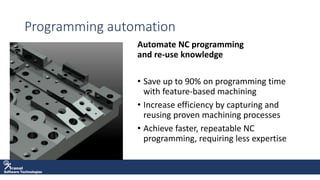

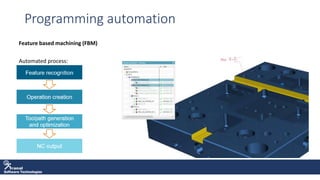

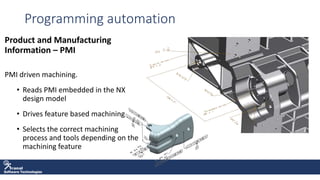

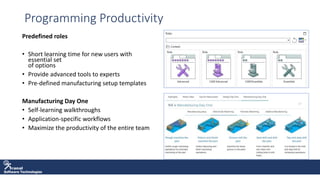

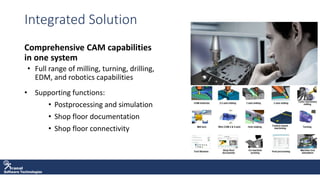

The document presents an overview of NX CAM, a computer-aided machining software, highlighting its capabilities in machining processes, including milling and turning, and addressing industry challenges. It outlines target market segments, programming automation, and integrated solutions for manufacturing, emphasizing benefits such as reduced training time and increased programming efficiency. Additionally, it details various advanced features that enhance the performance of machining operations across different industries.