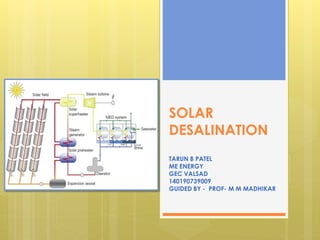

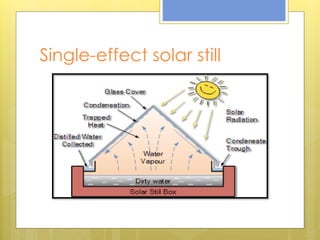

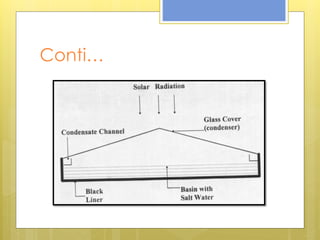

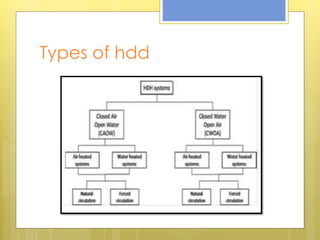

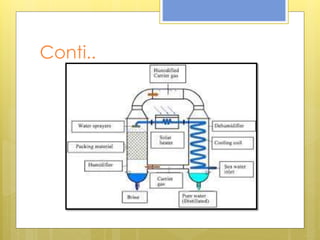

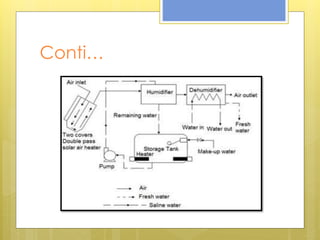

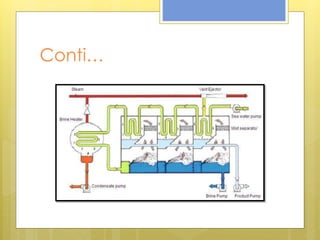

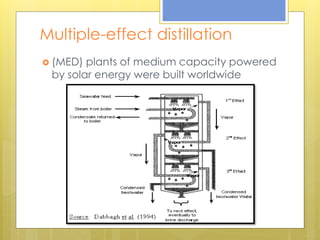

This document discusses solar desalination technologies. It begins by introducing conventional desalination methods like multi-stage flash distillation and reverse osmosis that are energy intensive. It then explains that solar desalination can help address future challenges of energy and water shortage. Solar desalination techniques include direct methods like solar stills and indirect methods that combine solar energy with conventional distillation. Both direct and indirect solar collection systems are discussed along with technologies like humidification-dehumidification that improve thermal efficiency. In conclusion, solar desalination offers a promising way to meet power and water needs in remote regions by providing alternatives to fossil fuel-driven processes.