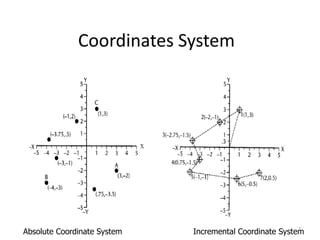

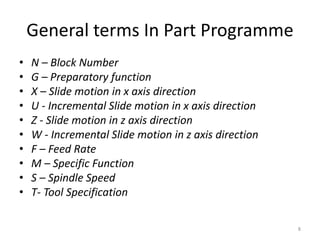

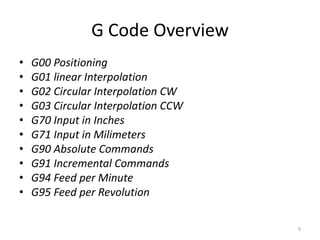

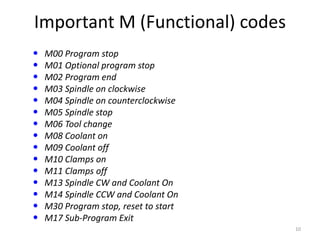

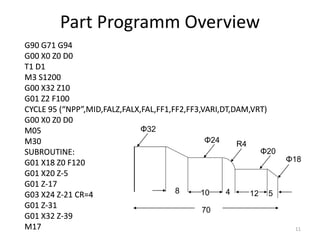

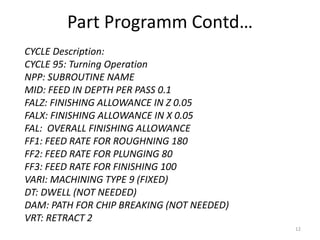

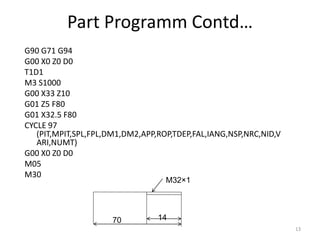

This document provides an introduction and overview of CNC turning. It describes what CNC turning is, the basic components of a CNC turning machine, important checklists and safety procedures, basic CNC principles including coordinate systems and programming codes, and includes examples of CNC part programs for turning operations and thread cutting cycles.