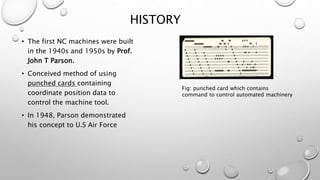

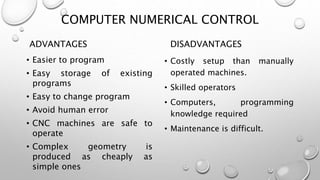

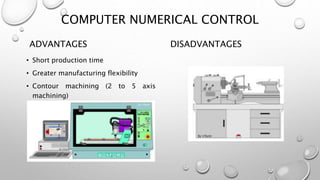

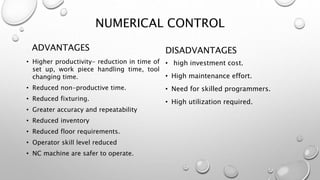

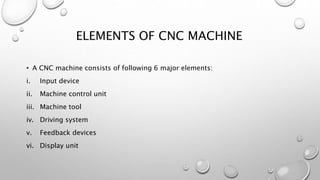

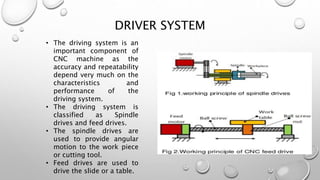

This document discusses computer numerical control (CNC) machines. It begins by defining CNC and its evolution from numerical control (NC) machines. It then describes how CNC machines work by using computer code converted from CAD designs to control tool and workpiece movement. The document outlines various applications of CNC in manufacturing like lathes and mills. It provides a brief history of NC machines and discusses advantages and disadvantages of CNC versus traditional machining. Finally, it details the key elements that make up modern CNC machines.