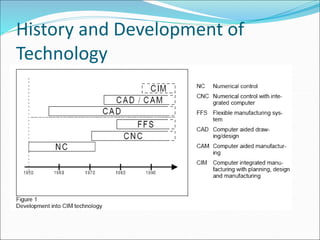

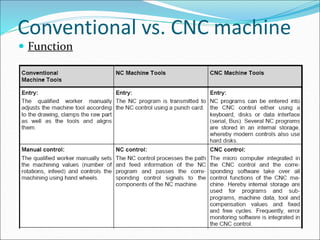

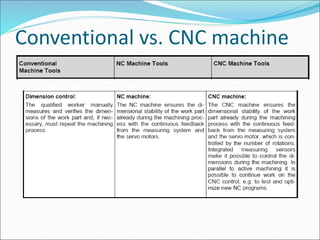

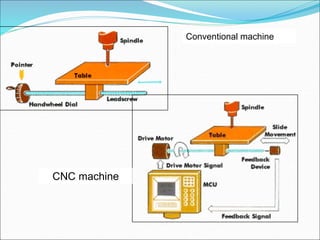

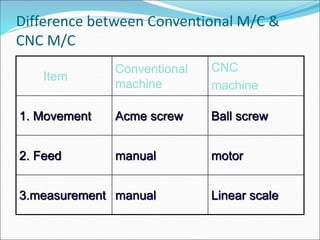

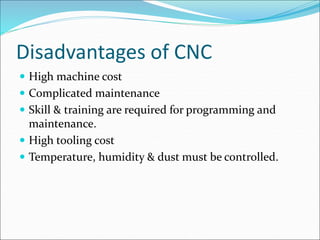

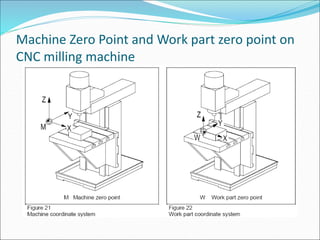

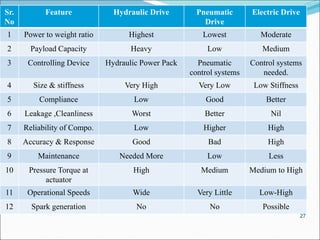

The document discusses CNC technology and tooling. It provides an introduction to CNC machines, describing their construction, components like axes and drives, and features like automatic tool changers. It explains the differences between conventional and CNC machines. The document also covers CNC tooling systems including tool materials, turning and milling tool geometries, modular tooling systems, and work holding.