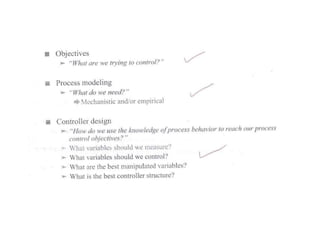

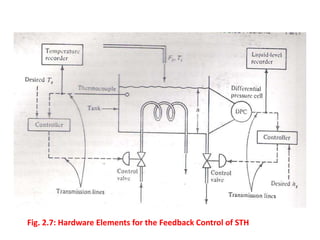

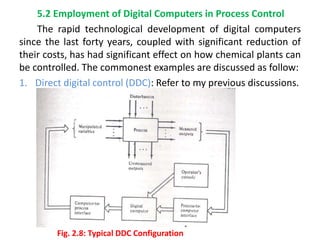

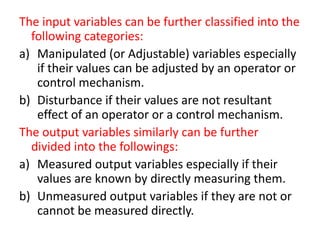

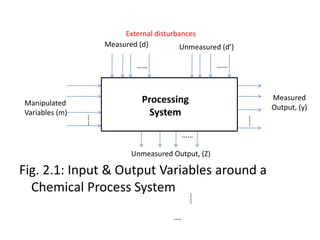

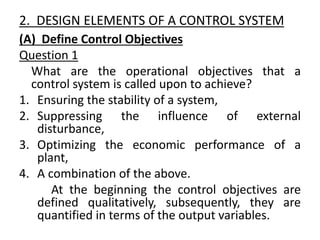

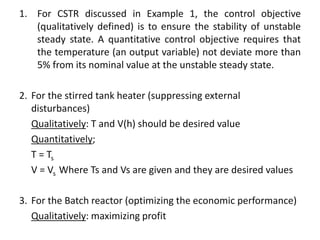

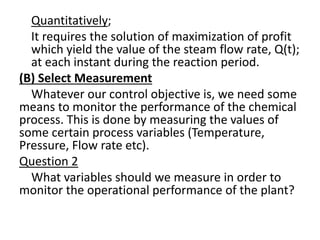

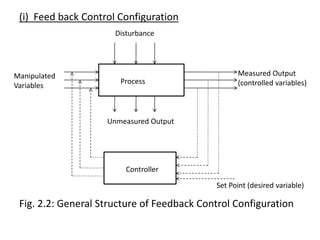

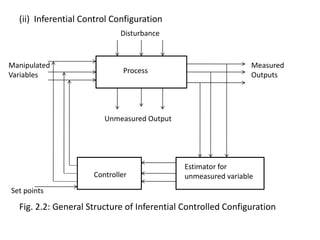

The document provides an overview of process dynamics and control, focusing on the design and hardware aspects of control systems in chemical processes. It discusses the classification of variables, design elements for control objectives, the selection of measurement and control configurations, and the development of controllers. Key hardware elements involved in process control, including sensors, transducers, controllers, and the impact of digital computers, are also highlighted.

![Diagrammatically

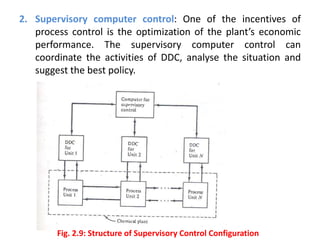

How T changes with time will be given by the

transient energy balance around the tank; that is

Subtracting eqn 1 from eqn 2, we have

Note that, since Ts = constant

Time

Ts

Ti,s

Ti

dT/dt

=

))/dt

T

-

(d(T s

(3

-

-

-

Qs)

-

(Q

+

Ts)]

-

(T

-

s)

Ti,

-

Cp[(Ti

F

=

Ts))/dt

-

Cp(d(T

V

(2)

-

-

-

-

Q

+

T)

-

Cp(Ti

F

=

d(T)/dt

Cp

V

](https://image.slidesharecdn.com/pdcmodule2-240703145538-ecae1d55/85/Presentation-on-process-dynamics-and-control-17-320.jpg)

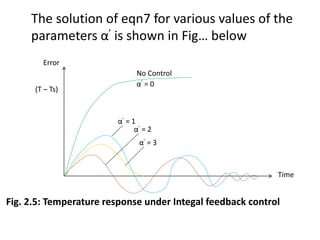

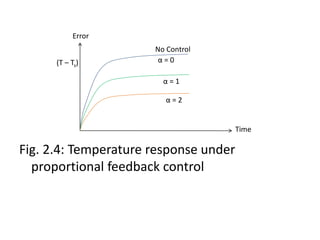

![VρCp d(T – Ts)/dt = FρCp[(Ti – Ti,s) – (T – Ts)] – α(T – Ts) -------- (5)

Eqn5 is solved for (T – Ts), and for various values

of gain and yield the solutions shown in Fig..

below. It’s noticed that more of the solutions is

satisfactory since T – Ts ≠ 0. Thus one concludes

that the proportional control law is not

acceptable.](https://image.slidesharecdn.com/pdcmodule2-240703145538-ecae1d55/85/Presentation-on-process-dynamics-and-control-19-320.jpg)

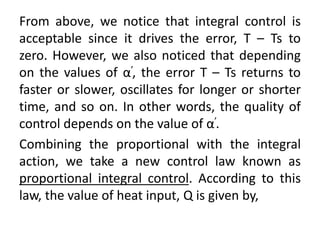

![However, considerable improvement in the

quality of the resulting control can be obtained

if one uses a different control law known as

integral control. In this case Q is proportional to

the time integral of (T – Ts); thus,

Substituting again Q from eqn6 into eqn3, we

have

(6)

-

-

-

-

-

-

-

-

-

Qs

+

Ts)dt

-

(T

'

t

0

Q

)

7

(

Ts)dt

-

(T

'

-

]

Ts)

-

(T

-

s)

Ti,

-

Cp[(Ti

F

=

Ts))/dt

-

(d(T

Cp

V

t

0

](https://image.slidesharecdn.com/pdcmodule2-240703145538-ecae1d55/85/Presentation-on-process-dynamics-and-control-21-320.jpg)