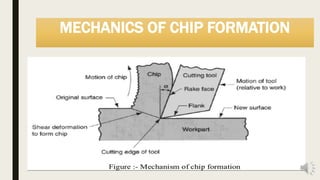

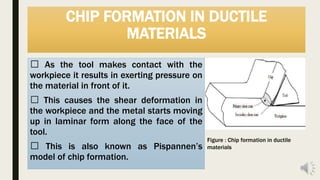

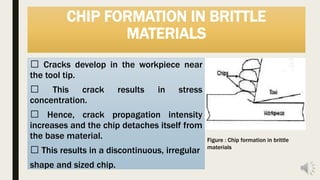

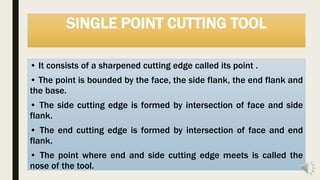

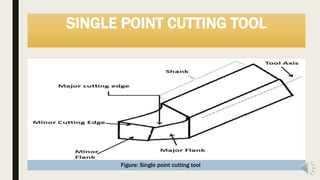

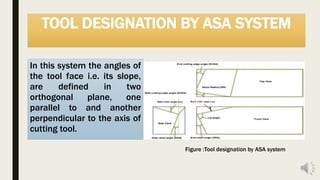

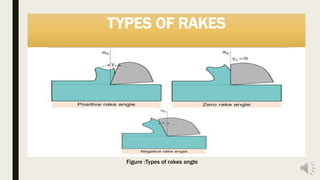

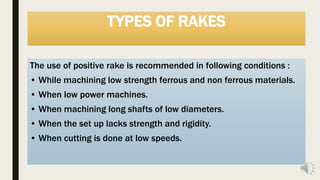

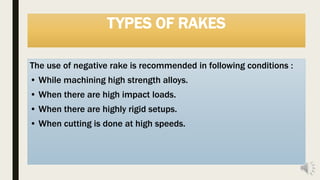

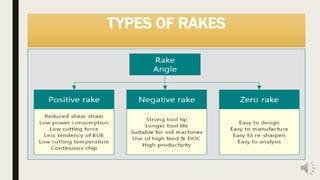

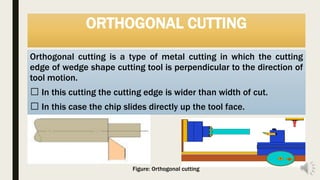

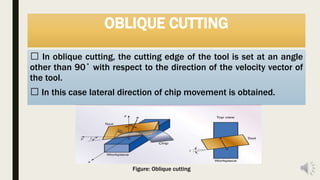

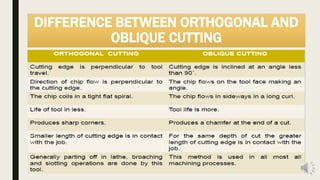

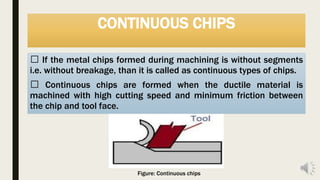

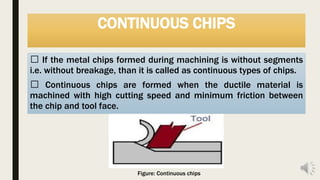

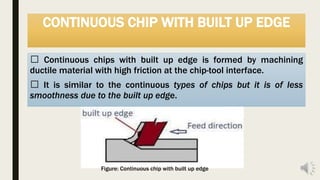

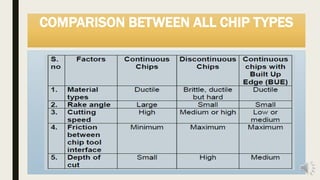

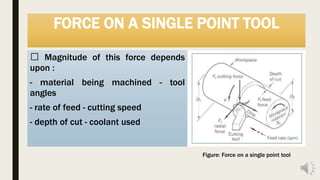

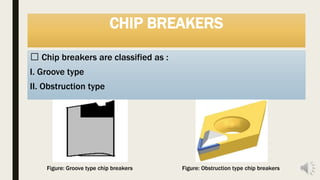

This document discusses chip formation and cutting tool geometry in metal cutting operations. It describes the mechanics of chip formation, where a wedge-shaped tool exerts pressure on the workpiece, inducing shear deformation and removing material in the form of chips. The types of chips formed depend on whether the material is ductile or brittle. Continuous, discontinuous, and continuous chips with built-up edges are discussed. The document also outlines the geometry of single point cutting tools, designation systems, types of rakes, orthogonal and oblique cutting methods, forces on tools, and the purpose and types of chip breakers used.