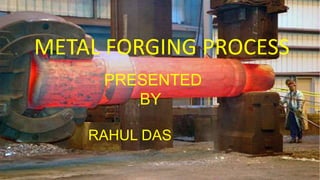

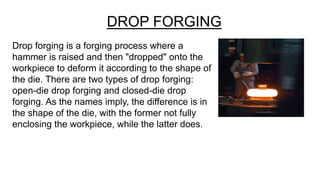

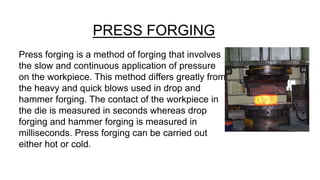

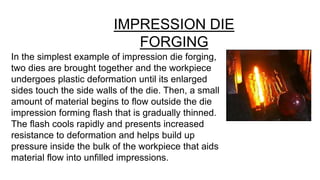

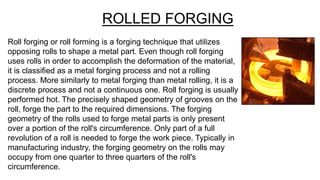

Forging is a metalworking process that involves shaping metal using localized compressive forces. It can be performed hot, warm, or cold. Forged parts range in weight from under a kilogram to 580 metric tons. Forging improves metals' strength and durability through grain refinement. There are several forging techniques including smithy forging (traditional hand forging), drop forging (using a hammer), press forging (applying continuous pressure), and roll forging (using opposing rolls). Forged parts generally require further processing to achieve their final shape. Common forgeable metals include carbon steels, aluminum, and titanium.