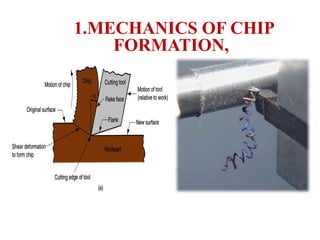

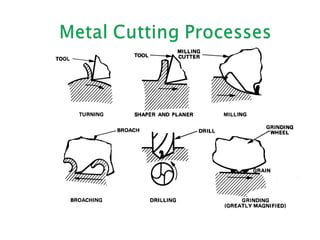

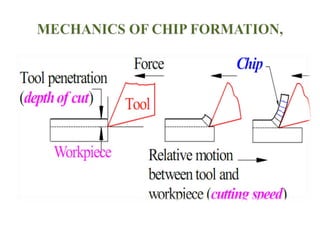

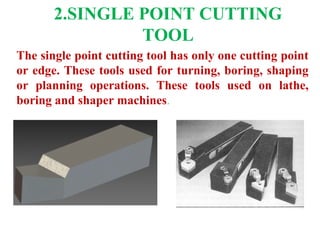

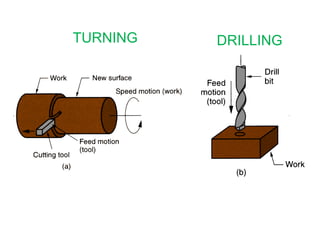

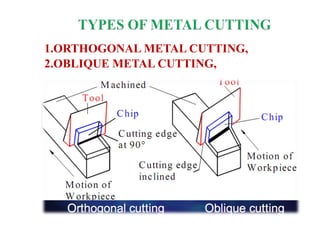

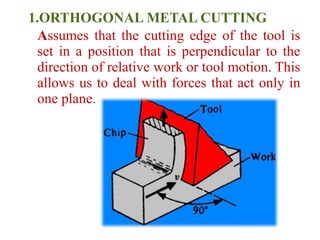

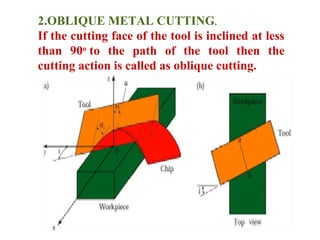

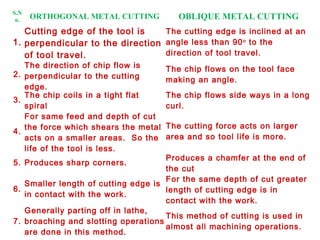

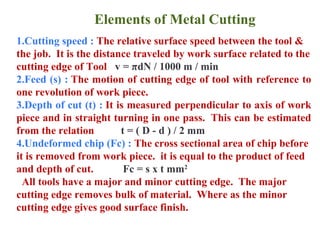

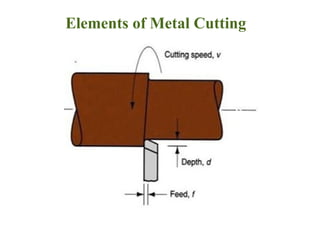

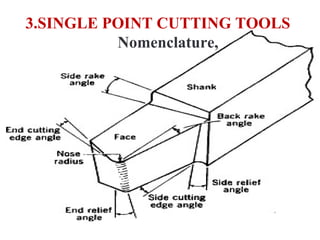

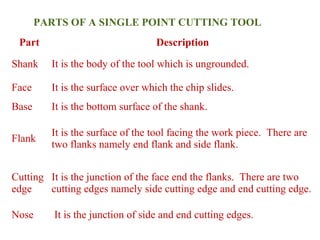

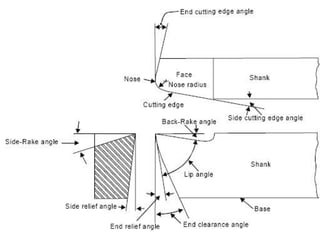

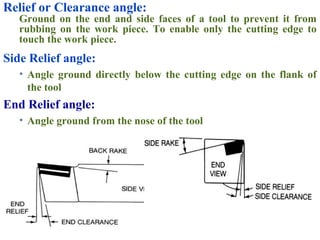

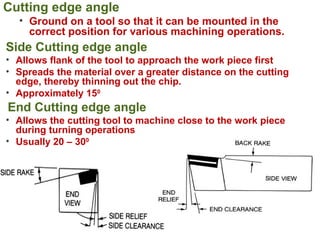

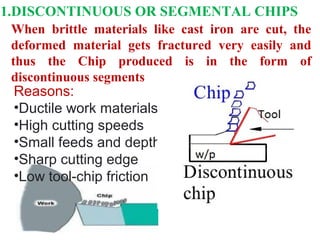

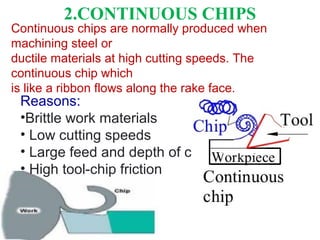

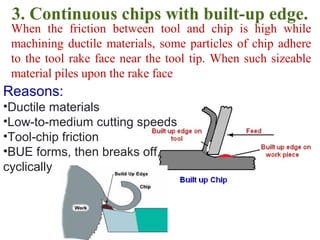

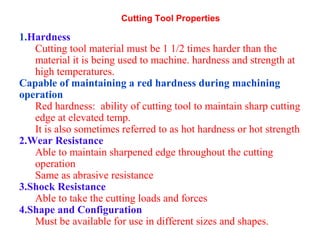

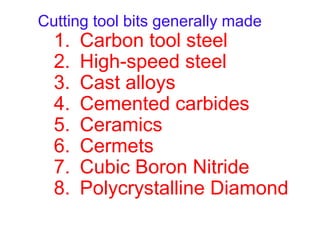

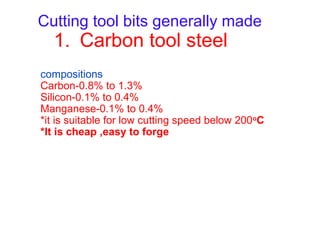

This document discusses the theory and mechanics of metal cutting. It begins by defining metal cutting as removing unwanted material from a workpiece through cutting, abrasion, or non-traditional processes. It then covers the basics of orthogonal and oblique metal cutting, tool geometry including rake and relief angles, and different types of chips that can form. The document also discusses important considerations for metal cutting like cutting speed, feed rate, depth of cut, and tool materials commonly used including high-speed steel, cemented carbides, and ceramics.