The document discusses high polymers and elastomers, highlighting the types and properties of polymers, including their formation through condensation and addition polymerization. It contrasts thermoplastics and thermosetting plastics, detailing the processes of fabrication and various molding techniques such as compression, injection, transfer, and extrusion molding. Additionally, it covers the chemical properties and uses of specific plastics, vulcanization of rubber, and copolymerization, as well as concepts like crystallinity and viscoelasticity in polymers.

![CHAPTER - 1. High Polymers and Elastomers

The compound formed by large number of small molecules (called monomers) linked together are known as POLYMERS

[poly = many].

Thus the single repeating unit is called as monomer, and the resultant high molecular weight compound is called as polymer.

Classification of polymers

Tacticity

a) Isotactic polymers

b) Atactic polymers

c) Syndiotactic polymers

In isotactic, the head to tail configuration in macromolecule

with respect to functional group is iso, i.e. all the functional groups lie

on the same side of the chain.

In atactic, the head to tail configuration is random i.e. the functional

groups are arranged randomly.

In syndiotactic polymers, the functional groups occupy the alternating

position.

Condensation/Step polymerization.

[May 2004, Dec.2004, May 2006, Dec.2006, May 2007, Dec. 2007]

The monomers having certain functional group such as -

OH, -COOH,

-N etc. show the tendency to undergo polymerizations by

the elimination of one molecule of a simple by-product such

as , Salt or alcohol etc. Unlike addition/chain

polymerizations, polymer loses simple molecules at every

combination.

Thus,

i. Condensation Polymerization is undergone by the monomers

which possess functional groups.

ii. Generally monomers are like acids, amines, alcohols,

phenols, carbonyl compounds etc.

iii. This type of polymerization occurs stepwise, hence the rate

of polymerization is comparatively low.

eg. Ureaformaldehyde

In the formation of ureaformaldehyde, hydrogen from group of urea condenses with oxygen to form ureaformaldehyde

with free valency and eliminates water molecule as shown in reaction.

These terminated groups further condense with formaldehyde to form long chains, thus the urea formaldehyde can be

represented can be represented as,](https://image.slidesharecdn.com/1highpolymersandelastomers-190323123653/85/1-high-polymers-and-elastomers-1-320.jpg)

![Plastics

The name plastic refers to its meaning that these are the polymers which mould themselves into articles by heat and pressure.

Comparison of Plastics

[Dec.2003, May 2005, Dec.2005, May 2006, May 2008]

Sr.

No.

Thermoplastics or thermosoftening

Plactics

Thermosetting Plastic or

Thermohaidening Plastics

1. These are formed by addition polymerization These are formed by condensation polymerization

only

2. They are long chain linear polymer with negligible

cross links

These have three-dimensional network structure with

number of cross links

3. Structural formula: Structural formula:

4. Monomer used in these is generally bifunctional In this, monomer used is of higher functionality

5. They have low molecule weight They have high molecular weight

6. They are usually soft, weak and less brittle. They are usually hard, strong and more brittle

7. They are usually soluble in some organic solvents. Due to strong bonds and cross links, they are insoluble

in almost all organic solvents

8. They get softened on reheating readily because second

ary force between the individual chain can break by

heat or pressure.

They do no soften on heating because the cross links

and bonds retain their strength on heating and hence.

9. They can be softened, reshaped and thus reused.

(reclaimed from waste) (by reheating to a suitable

temperature)

They retain their shape and structure even on heating.

Hence, they cannot be reshaped and reused. (cannot

be reclaimed)

10. Example : Polyethylene, polystyrene, PVC, PVA Example : Phenolformadehyde, ureaformaldehyde,

Nylon 6:6.

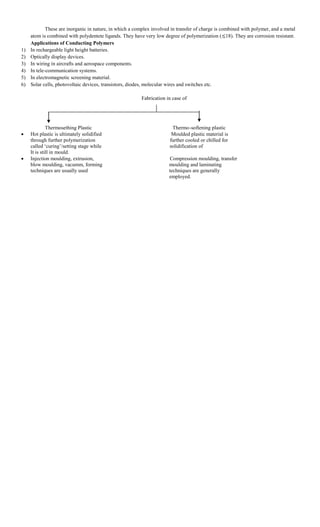

Fabrication of Plastics or Moulding of Plastics

[Dec.2003, Dec.2007, May 2008]

The fabrication is the process in which the prepared resins in the form of granules or powder are converted into desired shape

by using various machines or moulds.

The basic principle involved in this is partially melting (softening) resinous mass by the application of heat.

Compression Moulding

[Dec.2003, May 2005]

It is one of the most common method for moulding

thermosetting materials which can withstand high temperature

and pressure.

This process consist of compressing the molten resinous material

into the desired shape by the use of moulds, heat and pressure.

A predetermined quantity of resin powder of pallets is usually

preheated to about 120 C before the cavity of the heated mould

is filled with it.

After charging the mould, the two parts of moulds are carefully

brought together under low pressure. (Refer Fig.)

It is then compressed by hydraulic pressure.

Pressures from 2,000 to 10,000 p.s.i are used.

This pressure and heat allow the resin to melt and flow, thereby filling the cavity between the two parts of the mould.

The material in the mould is kept for the specified time under a correct temperature and pressure for a proper curve. The

curing is done either by heating (in case of thermosetting) or cooling (in case of thermoplastics).

After curing, the moulded articles are taken out by opening the mould apart.

A varity of products ranging from ash trays and elastric switch boxes to radio and television cabinets are manufactured this

way.

Injection Moulding

It is one of the most widely used processes for converting thermoplastic raw

materials into finish product.

It is fundamentally simple and capable of producing a very wide range of

industrial and domestic articles.

In this process a predetermined quantity of the granular or powdered resin is

fed into a heated cylinder from where it is injected at a controlled rate

through a nozzle into the tightly locked mould by means of a screw

arrangement or by position plunger as shown in the fig.](https://image.slidesharecdn.com/1highpolymersandelastomers-190323123653/85/1-high-polymers-and-elastomers-2-320.jpg)

![ Pressure upto 1758 kg/cm is used for injections. The mould is kept cold to allow the hot plastic to cure and become rigid.

When the material has been cured sufficiently, half of the mould is opened to allow the ejections of the finished article without

any deformation.

The entire cyclic operation may be made automatic.

This method is most widely used for moulding of thermoplastic because of high speed production, low mould cost, very low

loss of material and low finishing cost.

However, there are limitations of design of articles to be moulded because of large number of cavities cannot be filled

simultaneously.

Transfer Moulding

It is the method which uses the principle of injection moulding and is used for thermosetting materials.

When relatively intricate designs are required in the fabricated

products, especially when metal insets are to be fabricated, transfer

moulding is used.

Though transfer moulding is the combination of injection and

compression moulding, it differs from both these methods.

In this moulding, powdered resins are placed in the heated chamber,

maintained at a minimum temperature at which the powered resins

just begins to become plastic.

This plastic material is then injected through an orifice into the

mould by plunger, working at a high pressure.

Due to a very high friction developed at the orifice, the temperature

of the material at the time of ejection from the orifice rises to such an

extent that the moulding powder becomes almost liquid, and

consequently it flows quickly into the mould which is heated upto

curing temperature required for setting.

The moulded article is then ejected mechanically.

Advantages

1. Intricate shapes not attainable by compression moulding can readily be produced.

2. Article produced is free from flow mark.

3. Even thick pieces cure almost completely and uniformly.

4. Finishing cost of fabricated article is almost entirely eliminated.

5. Blistering is almost eliminated, since air and excluded gases are expelled in the plasticizing chamber itself.

6. Mould cost is less, since it involves very low abrasive action.

7. Fine wires and glasses fibers can be inserted into the mould.

Extrusion Moulding

[Dec.2005]

It is mainly used for manufacturing moulding articles of

thermoplastic resins.

For example tubes, rods, strips, insulated electric cable etc.

In this method dry moulding powder or granular material is

first fed through hopper into the rear of the heated chamber

which has a resolving screw.

When the screw is rotated the molten material is pushed

forward through the small orifice of the die to form

continuous uniform shaped articles.

When the article leaves the orifice, it is allowed to passed

through water for solidification of plastic material.

The control of the temperature of heating chamber and

speed of the extruder screw are the two most important

factors of successful extruder operation.

There are two types of moulding.

1. Vertical extruder moulding.

2. Horizontal extruder moulding as shown in the following fig.

Name Synthesis Properties Uses

[1]Poly

Styrene

(1) Polystyrene is a transparent, light (Sp.

Gravity 1.05 to 1.07 g/ ) and

stable material.

(2) It has excellent moisture resistance.

(3) it can be nitrated by fuming nitric and

sulphonated by conc. , at about

100 C to yield water soluble emulsion.

(4) It is a highly electric insulating material.

(5) It is highly resistance to acids and has a

In moulding of article like

(1) Toys, combs, buttons

(2) Bucket, radio and television

parts

(3) Refrigerator parts, battery

cases

(4) High frequency insulators

(5)Lenses

(6) Indoor-lighting panels etc.](https://image.slidesharecdn.com/1highpolymersandelastomers-190323123653/85/1-high-polymers-and-elastomers-3-320.jpg)

![good chemical resistance.

(6) it has a relatively low softening range

(90 to 100 C) and is brittle.

(7) It has an unique property of transmitting

light through curved section.

[2]PMMA (1) It is transparent and colourless plastic.

(2) Easy to mould in desired shapes.

(3) Refractive index is 1.59

(4) At lower temperature (R.T.) it is brittle

and rigid

(5) When heated slowly, acquires rubber

like properties at about 65 C where as so

items at about 130 C.

Use for making

(1) Artificial eyes

(2) Screens for T.V.

(3) Air crafts, light fixtures

(4) Also used in optical

instruments, bone splints,

adhesives, paints etc.

(5) In skylights, decorative

articles etc.

[3] Phenol

Formaldehyde

(1) They are scratch resistant, water

(2) resistant, water resistant and insoluble

solids.

(3) They possess excellent electrical

insulating character.

(1) For making electronic

(2) insulator parts like switches,

plugs, switch boards, heater handles etc.

(3) For making moulded articles

like telephone parts, cabinet

for radio and television etc.

(4) As a binder for grinding wheels.

(5) It is used in paints and

vanishes.

[4] Urea

Formaldehyde

(1) They possess good electrical insulating character.

(2) Resistant to water.

(3) Resistant to heat/flame.

(1) Used as a binder of glass fibers, rock wool etc.

which are used for

filtration and insulation purpose.

(2)Used in bonding plywood.

(3) Used as an electrical insulation.

(4) For decorative articles like

plates, drinking glasses, dishes etc

Urea formaldehyde

[Dec.2003, Dec.2004, May.2006,

May.2007, May.2008]

Synthesis

These are also called as amino resins

or amino plants.

In general amino organic compounds

and formaldehyde combine by

condensation polymerization to give

these resins.

In this particular types of resins,

organic amine being urea, reacts with

formaldehyde and polymerises to

give resins.

Reaction

Properties and Drawbacks of natural Rubber

[Dec.2003]

The natural rubber has following properties, (drawbacks) :

1. Its plasticity is greater than elasticity. It cannot sustain stress. Thus when stretched to a great extent, it undergoes deformation

permanently.

2. It has large water absorption tendency, which makes it weak.

3. It has very low tensile strength (20 kg/cm ).

4. Due to large percentage of unsaturation in its structure, it is easily attacked by various reagents such as , conc. ,

organic solvents, air, oxygen, ozone etc. and as a result gets gradually disintegrated.

5. It possesses high percentage of tackiness (Property of developing stickiness on surface) which makes it difficult to store the

rubber stocks.

6. Durability and abrasion resistance of natural rubber is very low.

Thus the natural rubber does not have the desirable properties.

Hence to make its maximum use, it is essential to improve its properties by means of certain catalyst.

Any catalyst used to improve the drawbacks of natural rubber is known as a vulcanizing agent, and the process by which the

undesirable properties of natural rubber are improved upon is known as vulcanization.

Vulcanisation](https://image.slidesharecdn.com/1highpolymersandelastomers-190323123653/85/1-high-polymers-and-elastomers-4-320.jpg)

![ [Dec.2004, May.2006, Dec.2006, May.2007, Dec.2007, May.2008]

To improve the properties of raw rubber, it is compounded with some chemicals like sulphur. , benzyl chloride etc.

Most important of all the process of compounding (vulcanizing) is the addition of sulphur.

The process consist of heating the crude rubber with sulphur to a high temperature.

The sulphur combines chemically at the double bond in the rubber molecule. Vulcanization brings about stiffening of the

rubber by a sort of cross-linking and consequently preventing inter molecular movement or sliding of rubber springs.

The extent of stiffness or loss of elasticity of vulcanized rubber depends upon the amount of sulpher added.

For example, a tyre rubber may contain 3 to 5% sulphur, but a battery case rubber may contain as much as 30% sulphur.

The changes in properties that take place due to vulcanization is shown as below :

Undesirable properties Improvement

Tacky Non-tacky

Weak Vulcanization Strong

Plastic Elastic

Soluble Insoluble

Advantages of using vulcanization

1) It has good tensile strength and extensibility when tensile force is applied.

2) It possesses low water absorption tendency.

3) It has much higher resistance to wear and tear.

4) It is a better electrical insulator.

Co-polymerisation

[May.2005, Dec.2007]

Copolymerization is nothing but specific type of addition polymerization.

In this the monomers of more than one type are involved.

Copolymerization has unique importance in the industry.

This is because products formed by copolymerization shown the specific properties of the monomers.

Sometimes such special properties are further enhanced or sometimes unique properties in the product as a result of the

reaction between two different types of monomers.

Thus copolymerization gives rise to variety of the products.

Thus several useful and commercially important polymers are formed by copolymerization.

e.g. Styrene butadiene rubber (SBR – GR – S)

Acrylonitrile rubber NBR or GR – A

Example : Ethylene copolymerized with propylene and also propylene copolymerised with butadiene gives rise to plastic

resistance to oxygen, and heat.

Properties of the copolymers depends on the relative amount of the two monomers constituting a polymers and also on the

type of monomer.

Polymer Crystallinity

[Dec.2007]

It is a property a polymer exhibits in varying extent, which is based on the pattern of arrangement of molecules of polymer.

A polymer is said to be „crystalline‟ if all molecules are arranged in orderly compact manner with symmetrical orientation,

with higher force of attraction between two chains.

Crystalline polymers generally,

1) Posses high density.

2) Strong, hard but brittle

3) Have sharp M.P.

This property can be calculated by density measurement of sample and of other known highly crystalline to highly

amorphous polymer. Then,

% crystallinity =

density of sample d – ensity of highly crystalline dc polymer

dc – da

Visco-elasticity of polymers

[Dec.2007]

Physical state of a polymer is governed by chain length and molecular weight.

Based on molecular weight, polymers are either elastic solids or viscous

liquids.

These physical states are temperatures servitive.

If cooled slowly, polymer becomes hard and brittle, and vice-versa.](https://image.slidesharecdn.com/1highpolymersandelastomers-190323123653/85/1-high-polymers-and-elastomers-5-320.jpg)

![ The time taken for cooling/heating also plays equally important role.

Thus with variation in temperature and time duration between the range of temperature, a polymeric material exhibits different

range of viscocities. This behaniour of a polymer is known as “viscoelasticity”

Melting and Glass Transition

[Dec.2007, May 2008]

The behavior of polymer with respect to its flow properties

is temperature sersitive.

When a polymer is cooled slowly, it becomes more and

more viscous, finally becomes hard solid and brittle. At this

stage polymer behaves like glass, and breaks if stressed.

Glass Transition temperature is defined as, “the lowest temperature beyond which the polymer becomes hard, glass-like and

brittle and the high temperature above which it becomes flexible, soft and elastic like rubber.”

It is denoted as and respectively.

Thus a polymer changes states as follows:

In viscoelastic state, polymer molecule has total flexibility, which diminishes beyond , and brittleness is developed.

Above , polymer is in molten state, where it does not exhibits and shape.

Thus between and , polymer can sustain stress, because all along the chains, the stress gets distributed almost equally.

As compared to is an important property for polymer because the value(or range of it)of helps to anticipate flow

properties/softening temperatures of polymers. By the different samples can be compared and selection of polymer for

desired moulding can be done more efficiently.

depends upon molecular structure presence of side chain, polar group and also on chain length iucluding frequency of

repeating groups along chain. The geometry of molecule also influences .

Example : increases if aromatic ring is present or high M.W, stronger intermolecular forces of attraction, coiling of

molecule etc.

Supra molecular chemistry and molecular electronics

[May.2008]

Supra molecular chemistry is a relatively new field of chemistry which focuses quite literally on going “beyond” molecular

chemistry.

It can be describe as the study of systems which contain more than one molecule, and it aims to understand the structure,

function and properties of these assemblies.

Examples of super molecular systems include biological membranes , polynuclear metal complexes, liquid crystals, and

molecule-based crystals.

A cell (very complex) supermolecular system biopolymers such as nucleic acids, and proteins.

A supermolecular assembly is a multi component system of atoms, ions and/or molecular, which are held together by non-

covalent interactions such as hydrogen bonds, van der waals forces, pi-pi interactions, and/or electrostatic effects.

The latter mode of bonding is particularly important for assemblies involving metal ions.

These various bonding interactions are far weaker than covalent bonding (which are the kind of bonds which hold molecules

together) therefore supermolecular assemblies are usually far less stable than molecular compounds (for example, they can be

more susceptible to breaking apart at high temperatures or if they are mixed with acid).

Formation od Supermolecular Assemblies

[May.2008]

The most common method is to use self-assembly techniques, in which the different components are mixed under given set of

conditions (solvent, temperature, pH etc.) and then they are allowed to form assembly.

Such self-assembly process form a single product which is result of the countless possible combinations of the starting

materials.

Such supermolecule (product) is formed because it is the most thermodynamically stable arrangement of the constituent

entities.

If in case the combinations take some wrong path which may be thermodynamically unfavoured, the molecule breaks

immediately.

This type of „reversibillity‟ id one of the unique features of supermolecular synthesis and this is the major difference between

the molecular synthesis and the conventional molecular synthesis involving covalent bonds.

In molecular synthesis, a reaction which goes down the „wrong pathway‟ often ends up at a dead end and the material which is

formed must in the end be separated from the desired product.

One of the major goal of supermolecular chemists is the synthesis of supermolecular assemblies which have new functions

that cannot appear from a single molecular or ion.

These functions are based on novel magnetic properties, light responsiveness, catalytic activity, fluorescence, redox properties,

etc., of super molecular systems.

These useful properties may lead to the application of these assemblies as and thse is the list of random examples high-tech

sensors for pollutants in air or water, compact information storage device for next-generation computers, as high-performance

catalysts in industrial processes, or as contrast agents for CAT scans.

Supermolecular chemistry is intimately related to nanotechnology, and many promising nanotech devices are based on the

principles of supermolecular chemistry.](https://image.slidesharecdn.com/1highpolymersandelastomers-190323123653/85/1-high-polymers-and-elastomers-6-320.jpg)