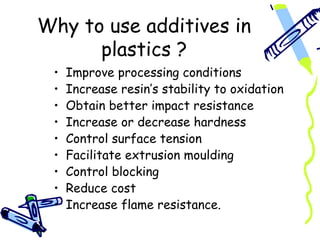

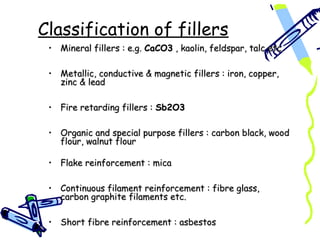

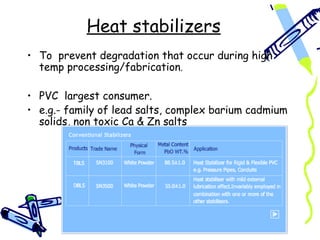

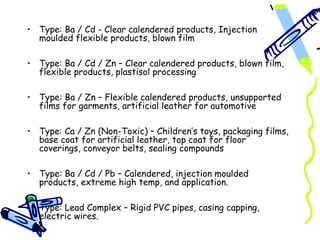

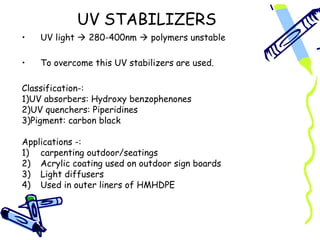

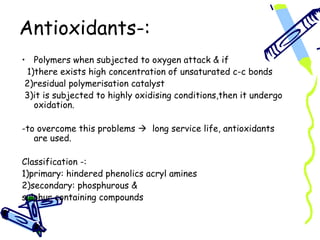

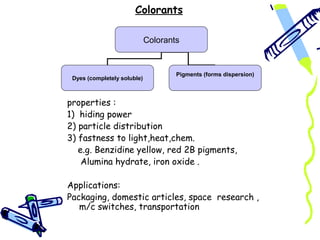

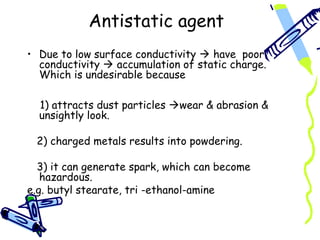

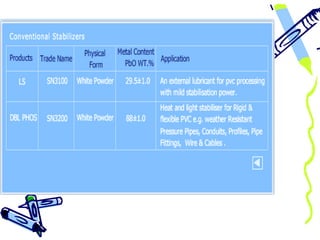

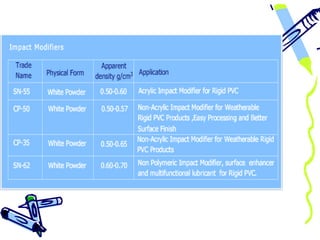

This document discusses various types of additives used in plastics, including their purposes and applications. It describes additives like fillers, antioxidants, heat stabilizers, UV stabilizers, colorants, antistatics, flame retardants, cross-linking agents, blowing agents, lubricants and impact modifiers. Additives are used to improve processing, increase stability, obtain better properties like impact resistance and hardness, control factors like surface tension, reduce costs, and increase flame resistance of plastics. The document provides classifications and examples of different additive types.