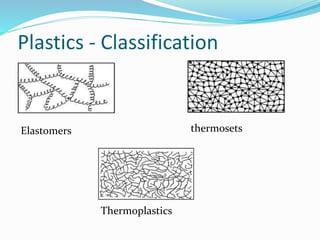

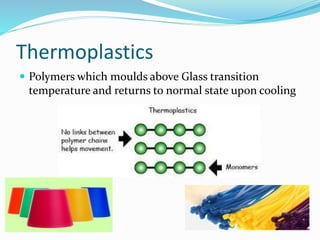

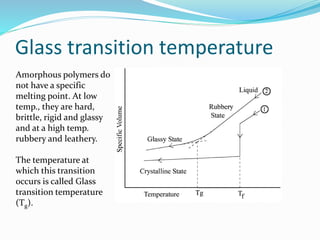

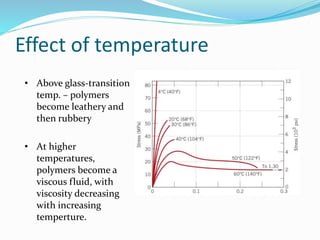

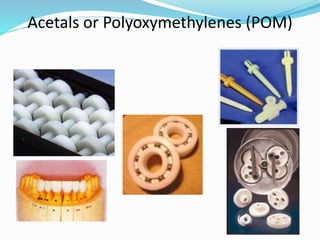

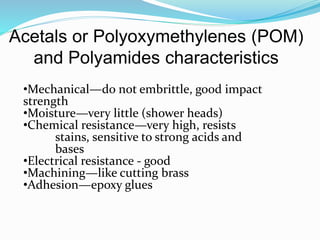

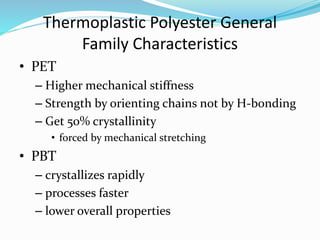

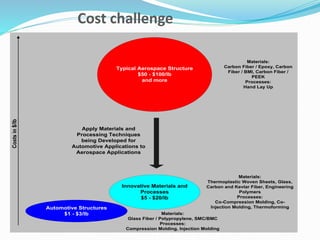

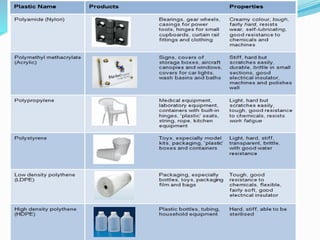

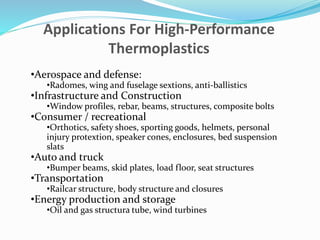

The document discusses advanced manufacturing techniques using plastics and thermoplastics. It begins by describing some limitations of conventional materials and how plastics offer benefits like ease of manufacturing and versatility. It then classifies plastics into thermoplastics, thermosets and elastomers. The bulk of the document focuses on thermoplastics, describing their properties including glass transition temperature, behavior under temperature conditions, orientation, and water absorption. Examples of commonly used thermoplastics are provided along with applications and potential future developments in the field.