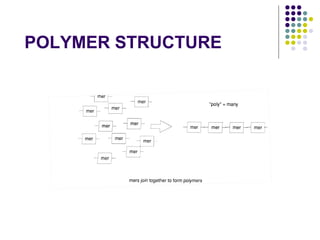

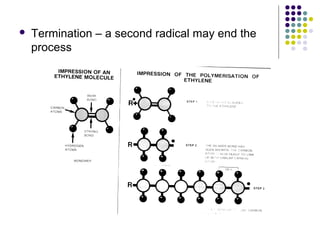

This document discusses various types of plastics, additives, and production processes. It describes the molecular structures of polymers as linear, branched, or cross-linked. It also explains the three main polymerization reactions - addition, condensation, and copolymerization. Finally, it outlines several common plastic materials and processing methods like injection molding, blow molding, and vacuum forming.