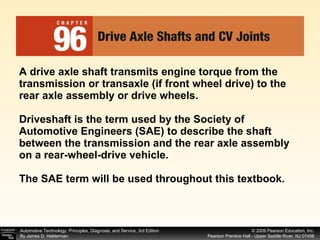

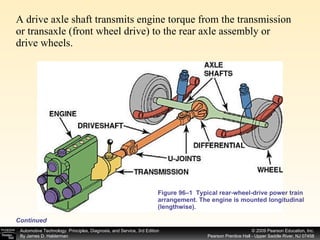

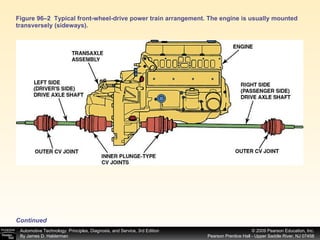

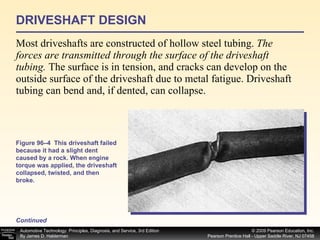

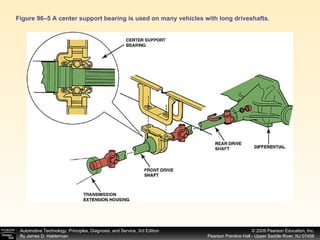

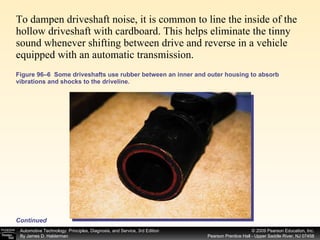

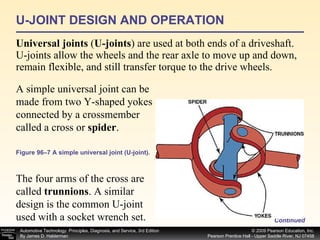

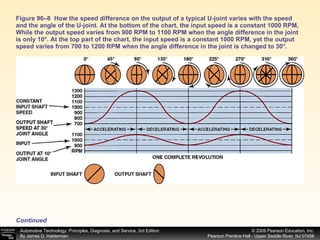

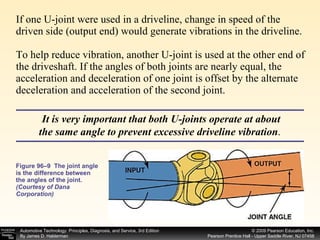

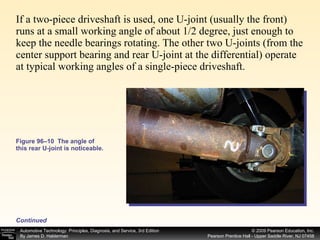

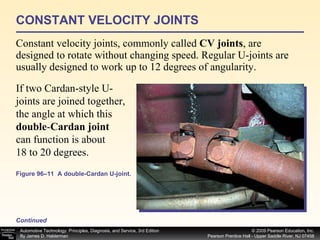

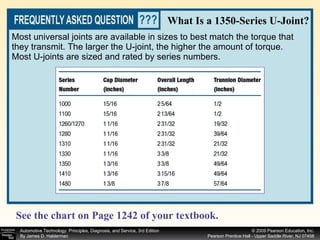

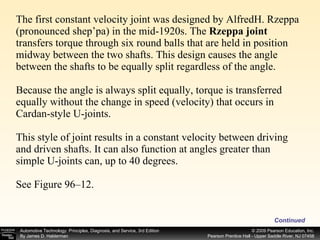

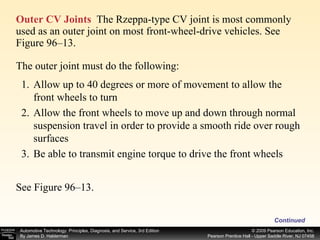

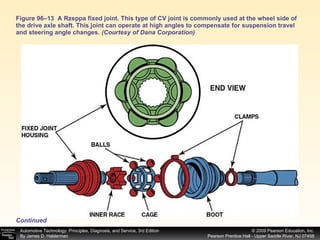

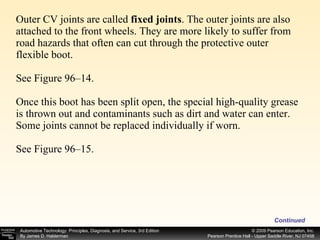

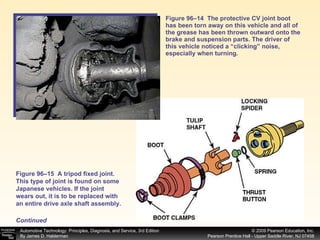

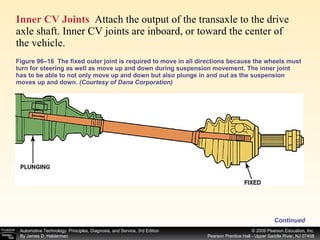

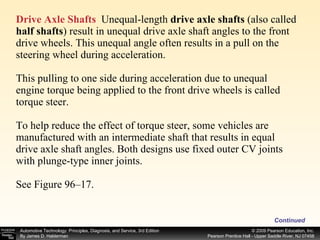

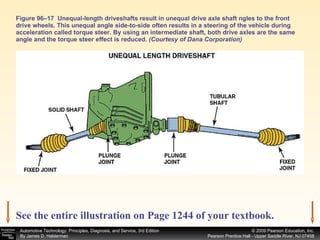

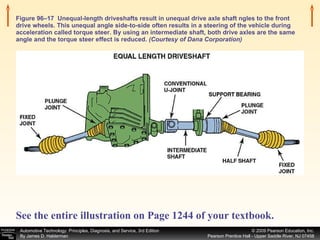

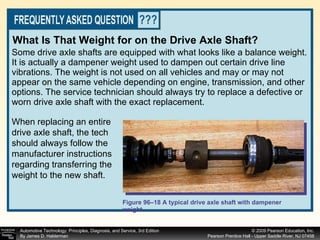

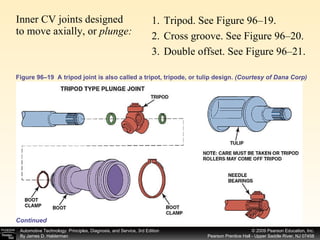

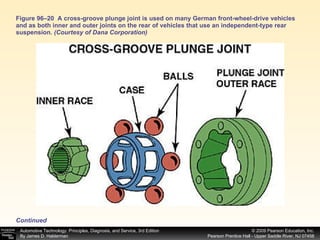

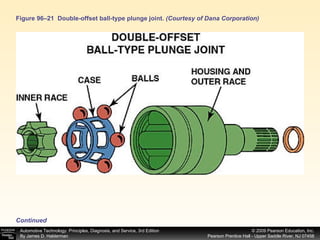

The document discusses drive shafts, U-joints, and CV joints used in vehicle suspension and steering systems. It defines key parts like the driveshaft, U-joints, and CV joints. It describes how U-joints and CV joints work, the different types of each, and their functions in transferring power from the transmission to the wheels while allowing for suspension movement. The document also discusses driveshaft design, balancing, and materials as well as factors that affect vibration.