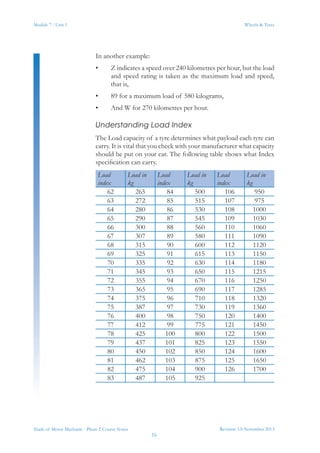

The document provides comprehensive training notes for Unit 1 of Module 7 on wheels and tyres for motor mechanics, covering essential topics such as health and safety procedures, types and construction of wheels and tyres, and practical skills including tyre changing and maintenance. It includes detailed information on the features, design specifications, and safety requirements associated with automotive wheels and tyres, as well as guidelines for diagnosing tyre wear and ensuring compliance with regulations. By the end of the unit, apprentices are expected to demonstrate their understanding and ability to perform various tasks related to wheels and tyres.