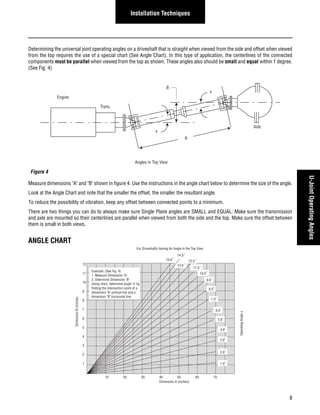

This document provides safety and installation guidance for driveline components. It discusses three main causes of vibration: imbalance, critical speed, and universal joint operating angles. It emphasizes the importance of balancing driveshafts to prevent imbalance issues. It also explains how to calculate the safe operating speed of a driveshaft to avoid resonating at its critical speed. Installers are advised to select components rated for the calculated torque loads and ensure operating speeds do not exceed the safe limits.