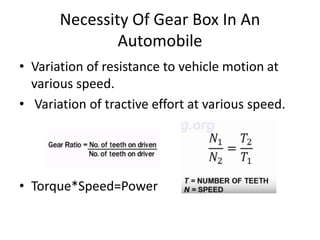

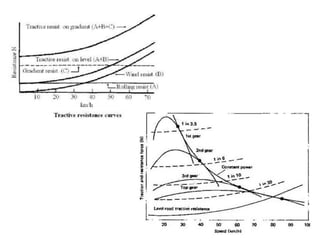

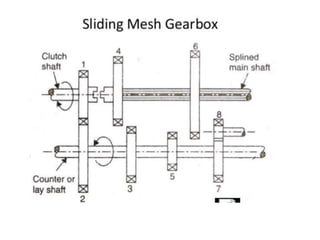

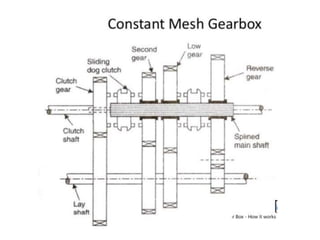

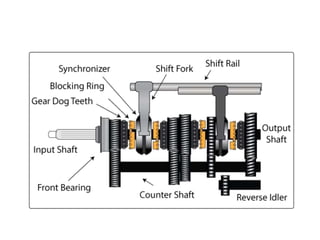

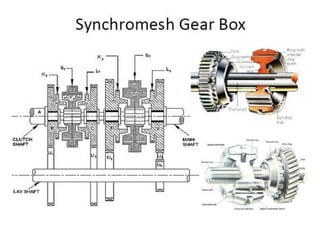

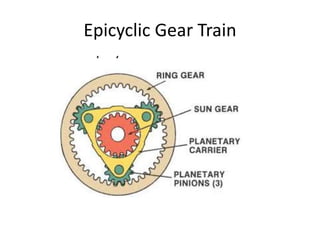

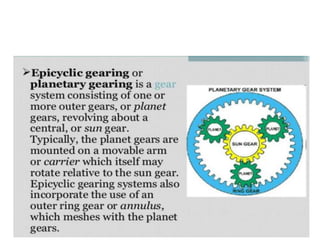

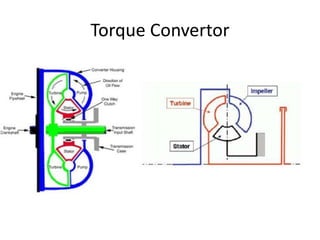

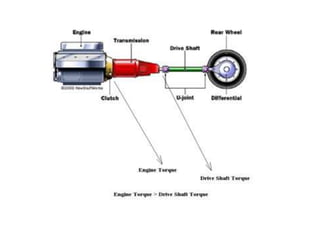

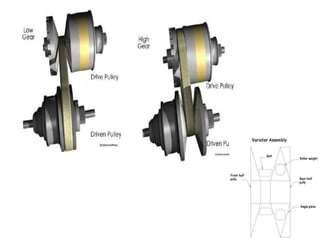

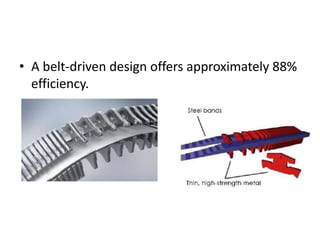

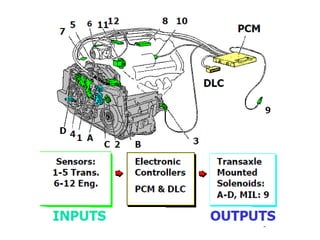

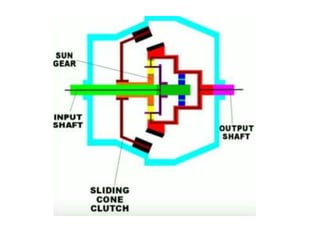

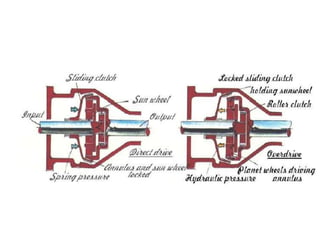

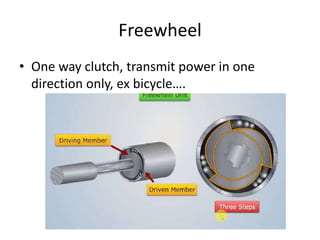

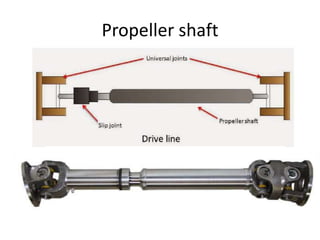

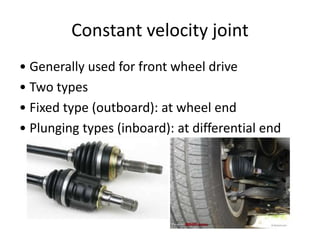

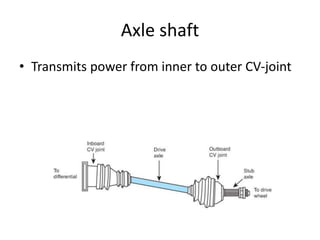

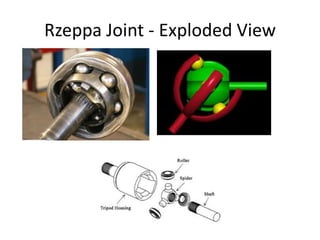

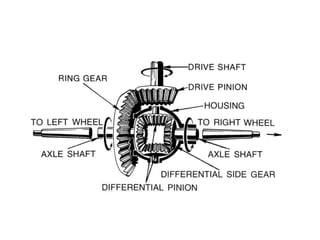

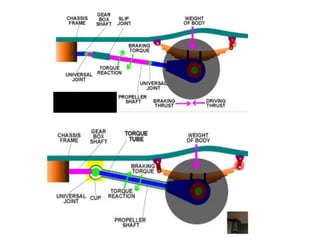

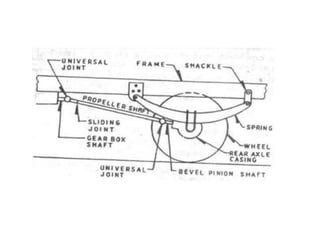

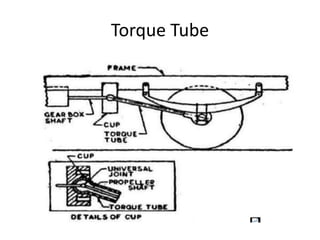

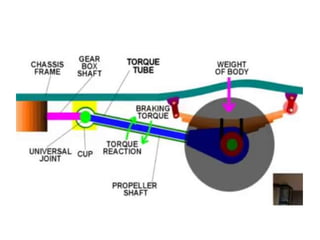

This document provides information on various components of automobile transmissions and gearboxes. It discusses the functions of gearboxes including varying torque ratios for acceleration and climbing gradients. It describes different types of transmissions including sliding mesh gearboxes, constant mesh gearboxes, and gearboxes with synchromesh or dog clutches. Continuously variable transmissions, torque converters, propeller shafts, differentials, axles, and the hotchkiss drive system are also outlined. Electronic transmission controls, overdrive systems, freewheels, universal joints, and power flow through the drivetrain are summarized as well.