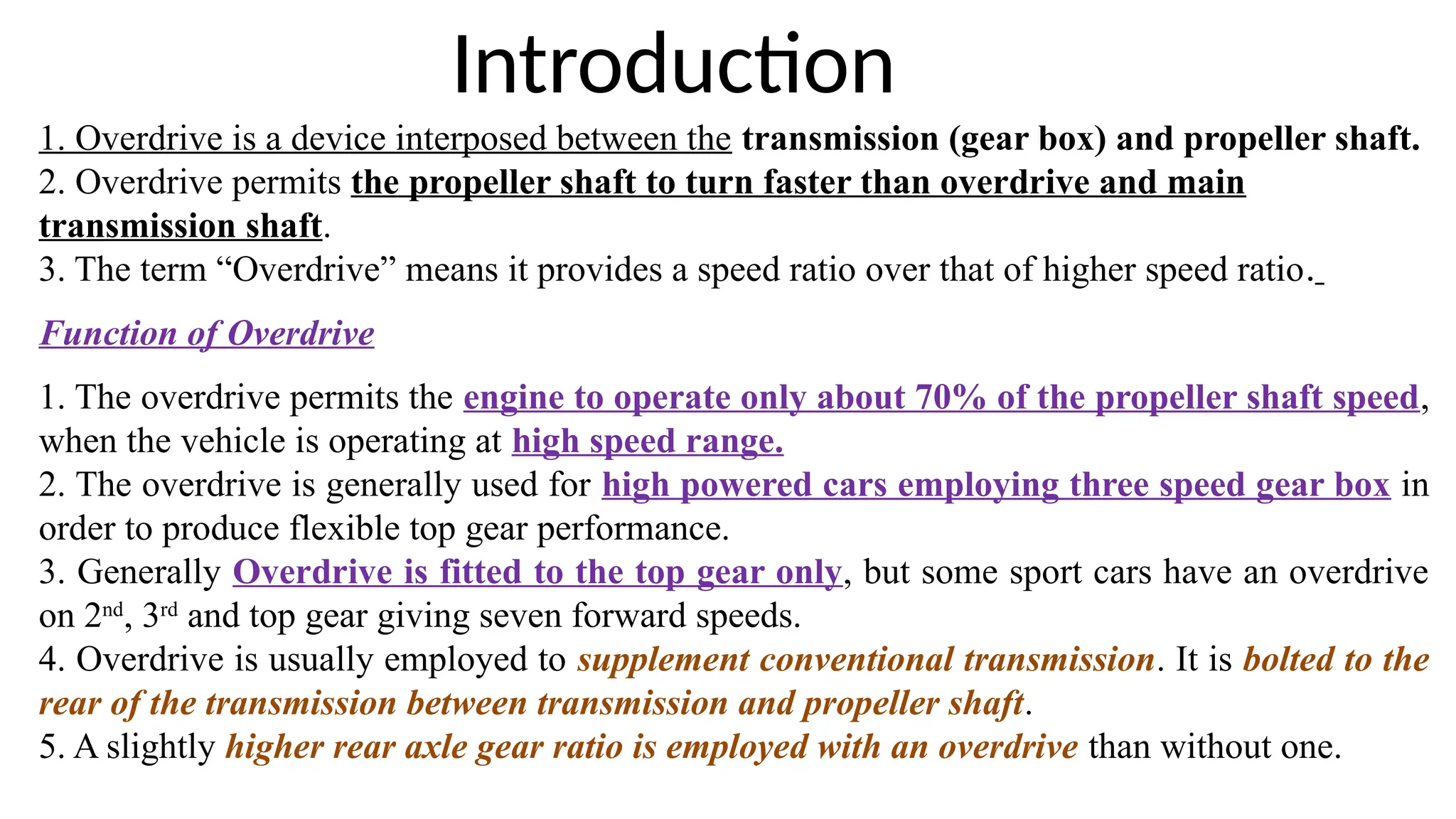

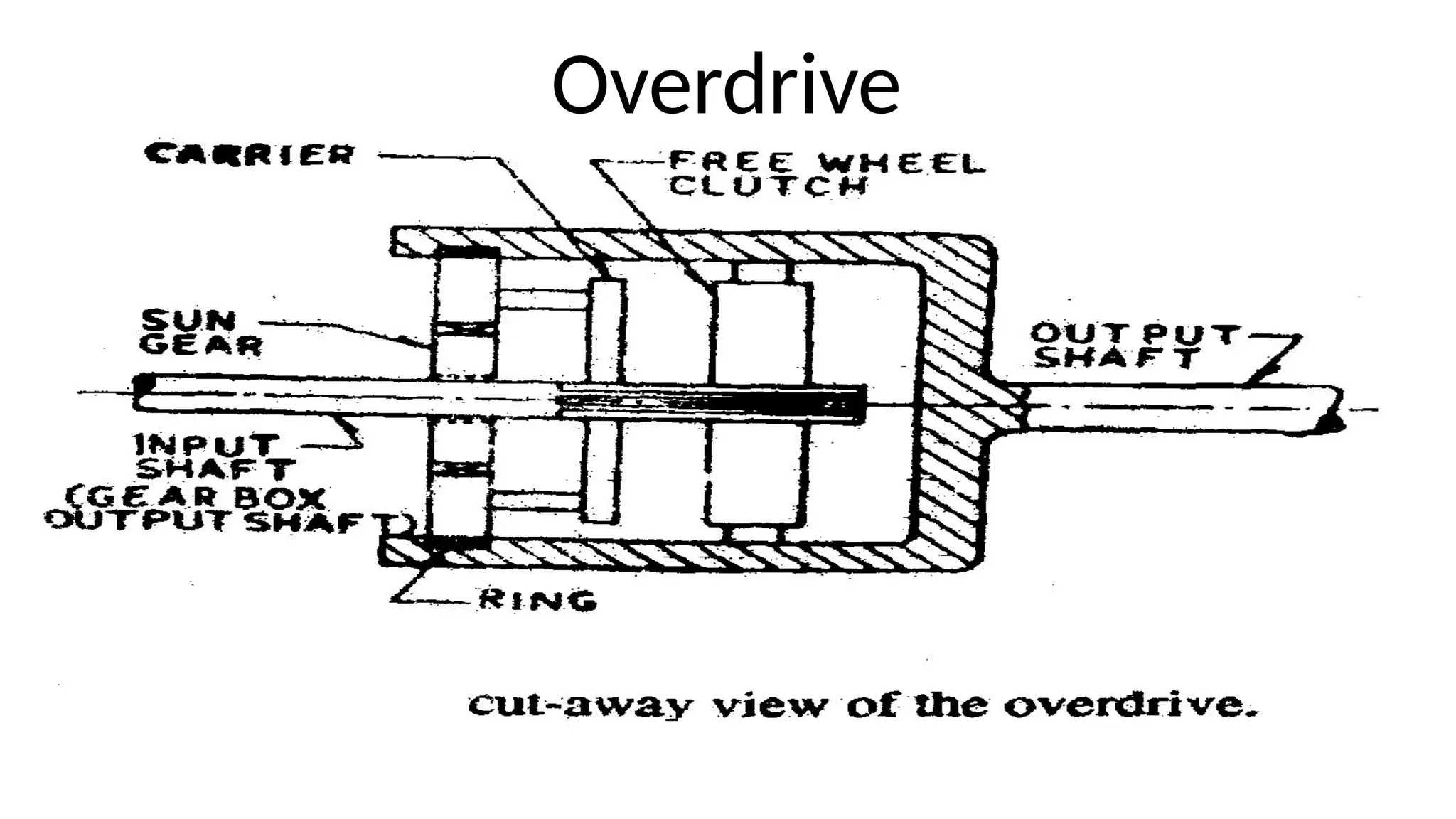

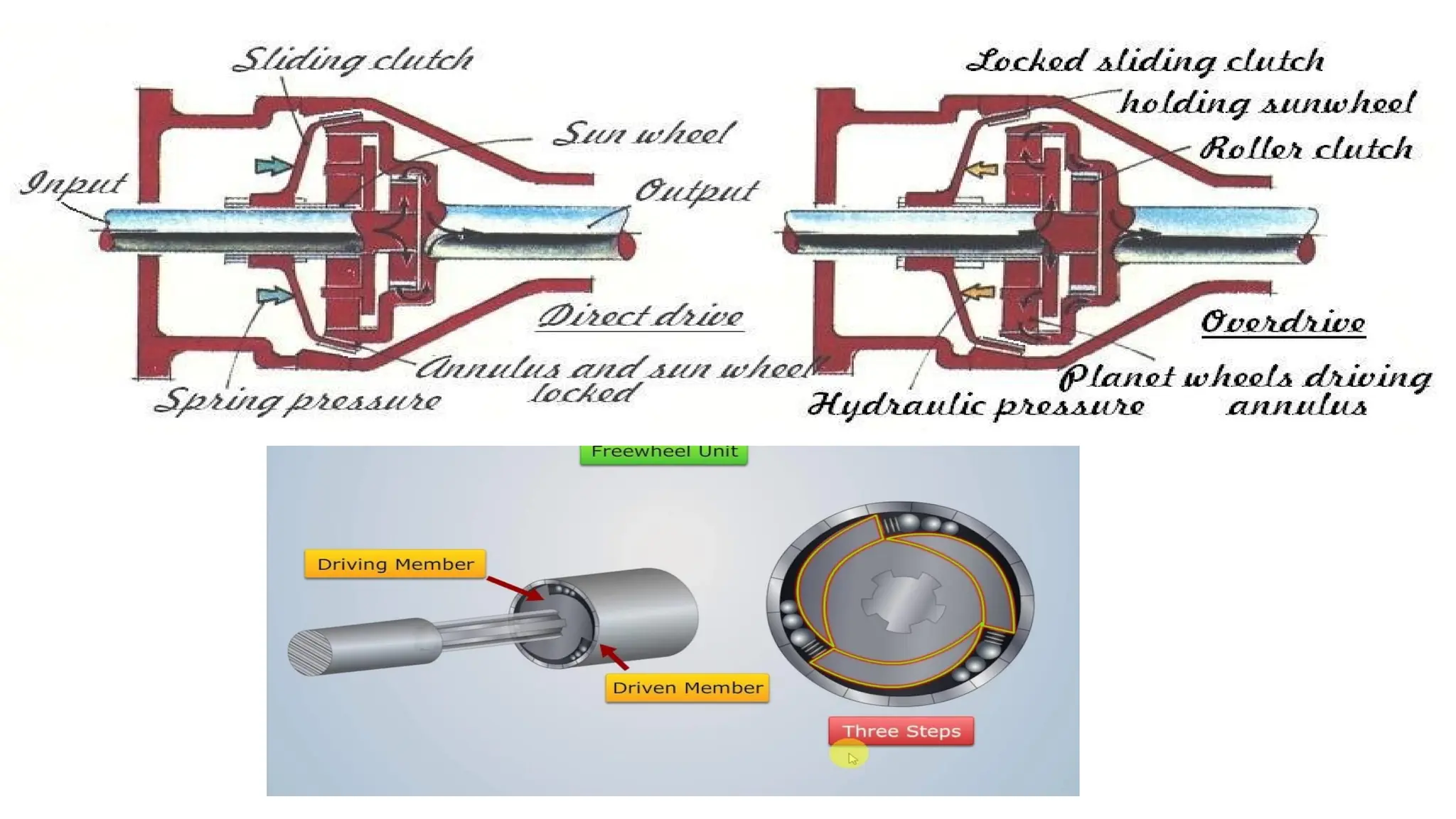

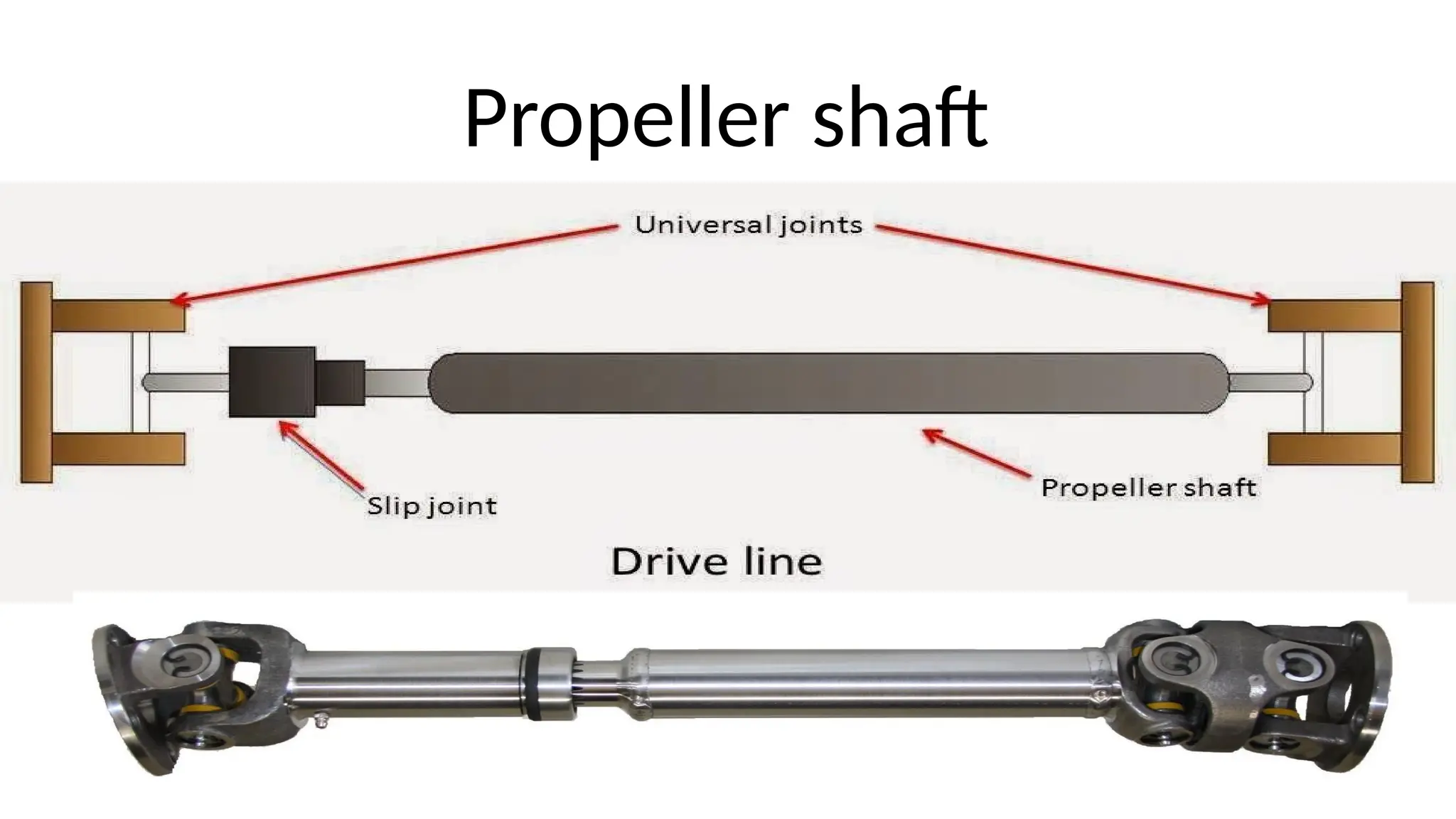

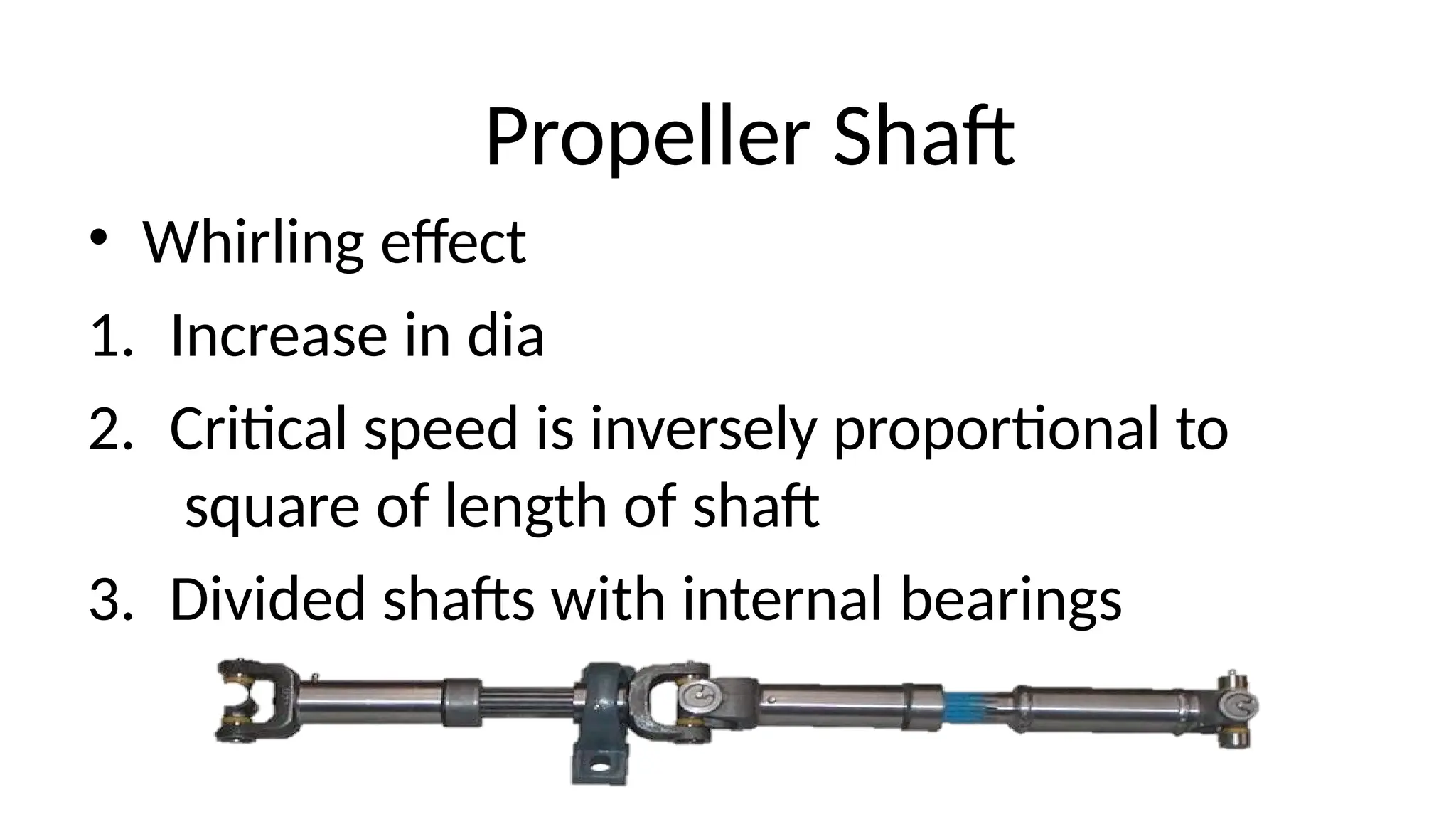

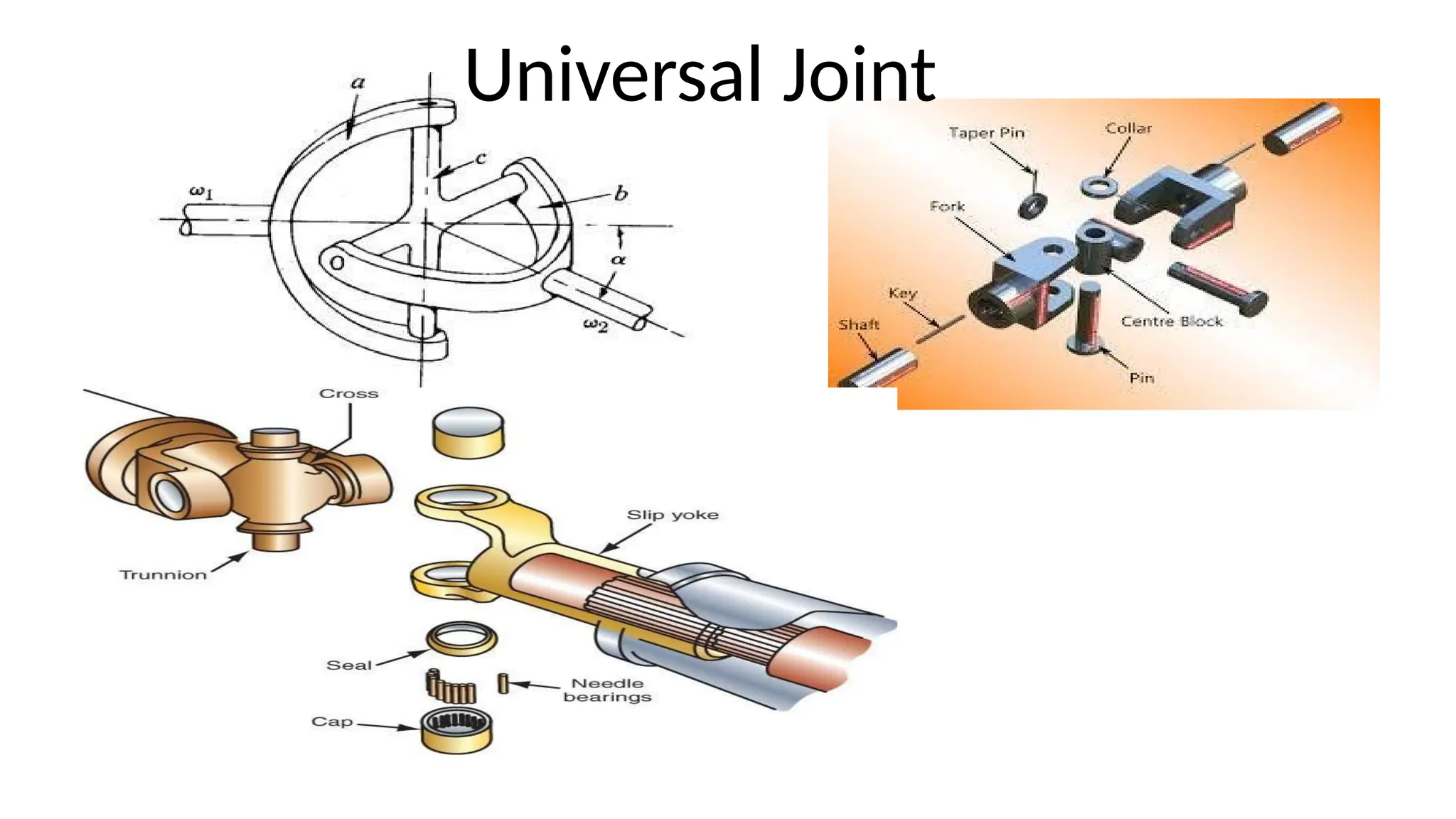

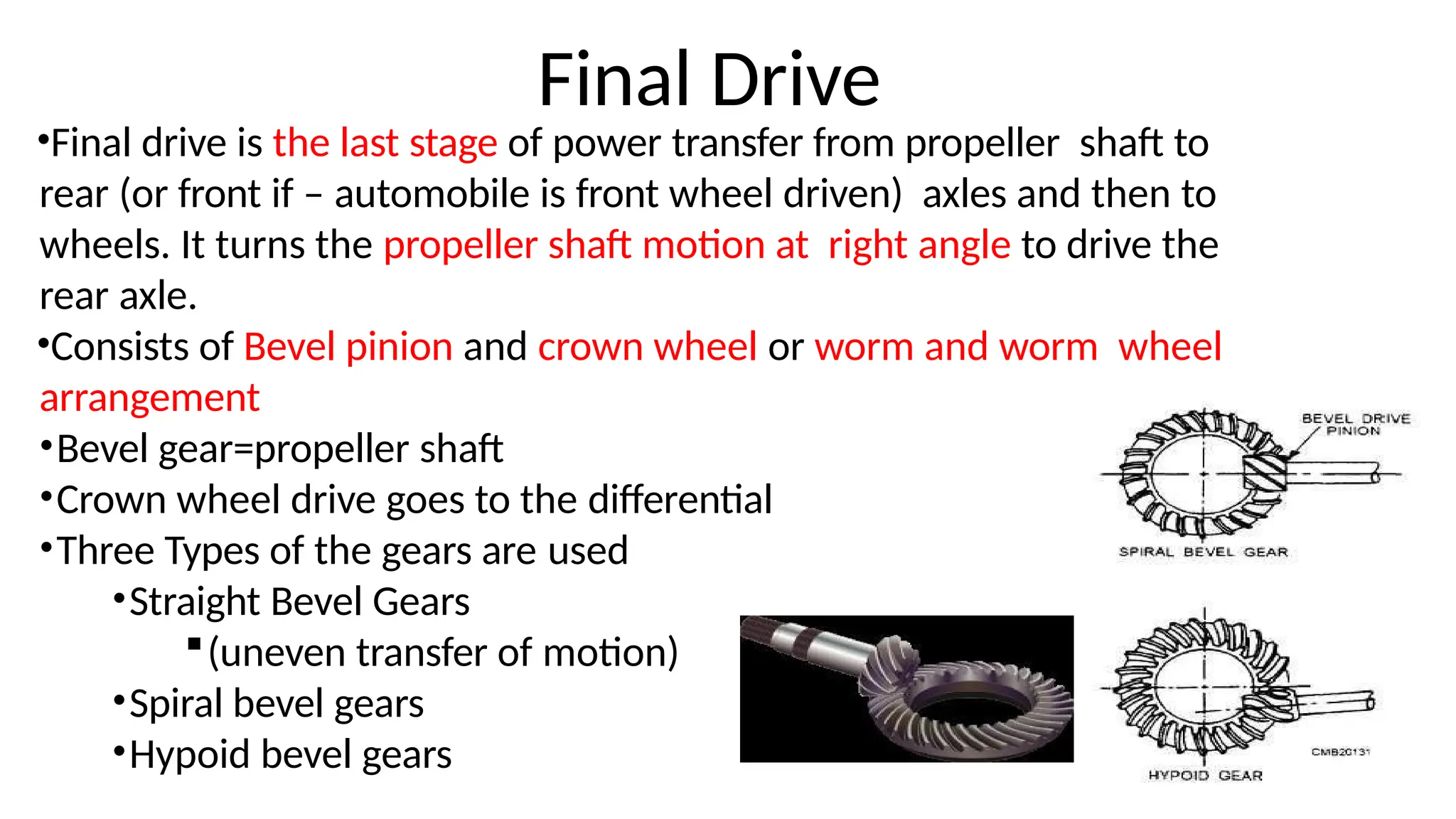

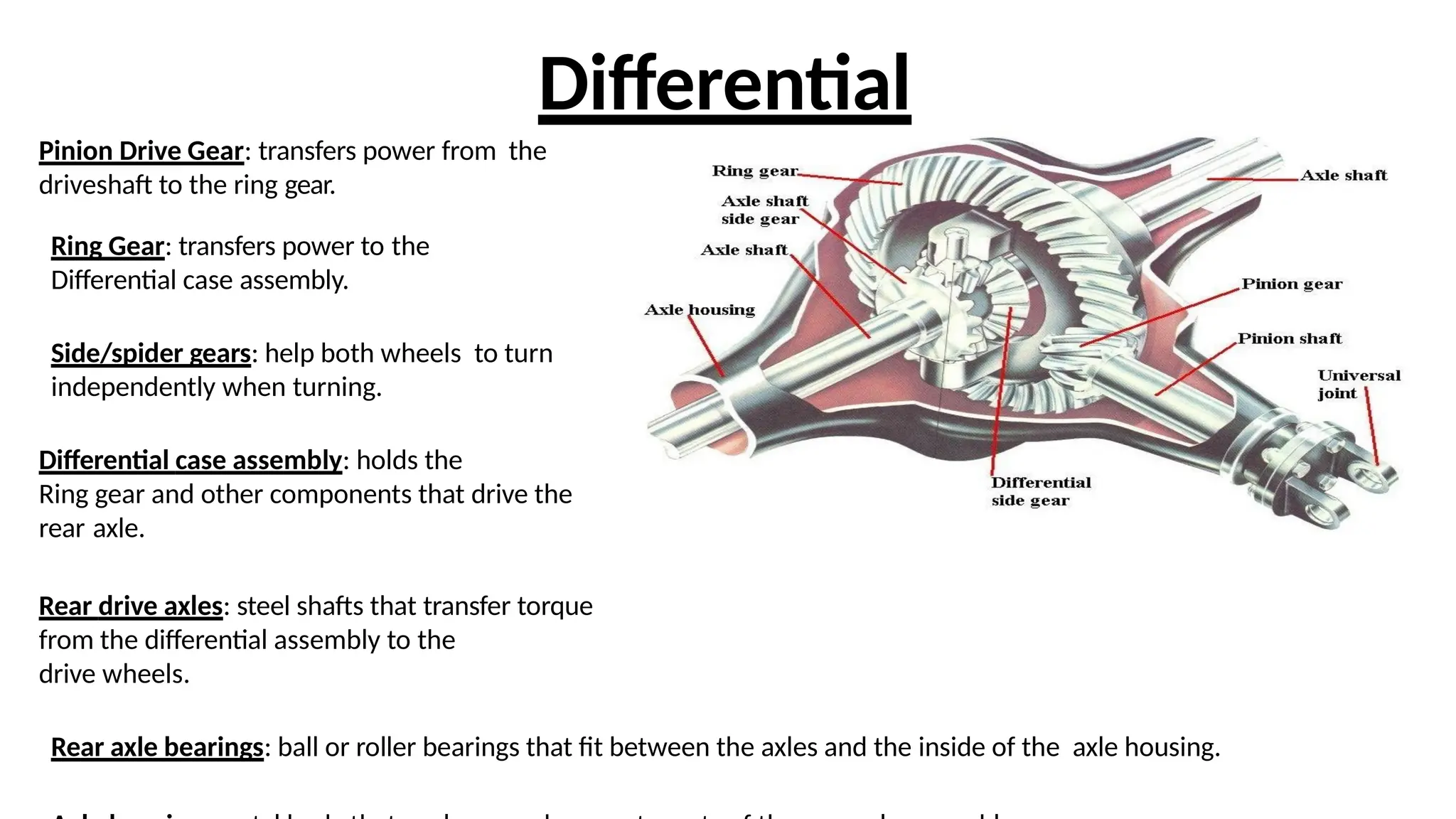

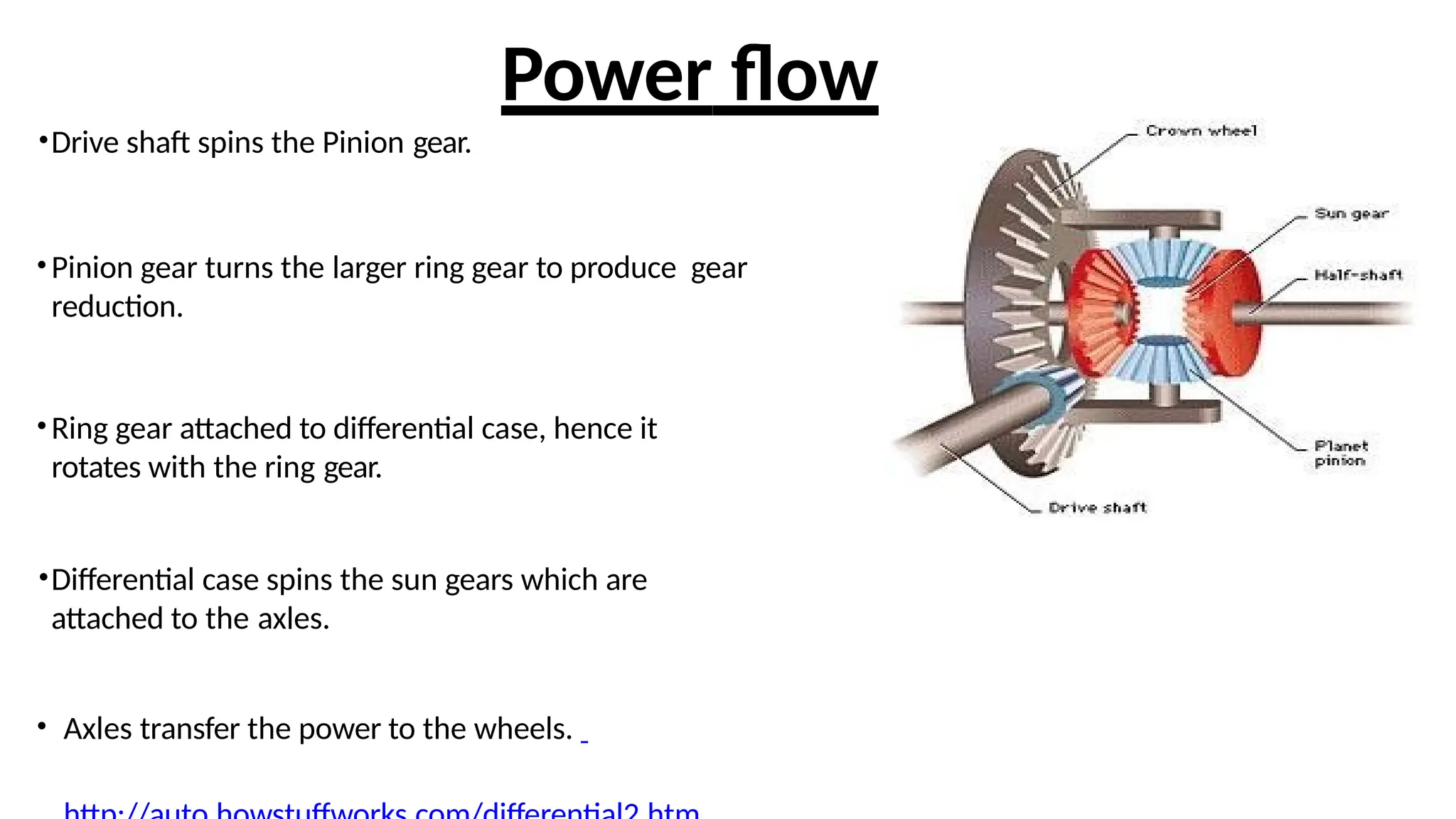

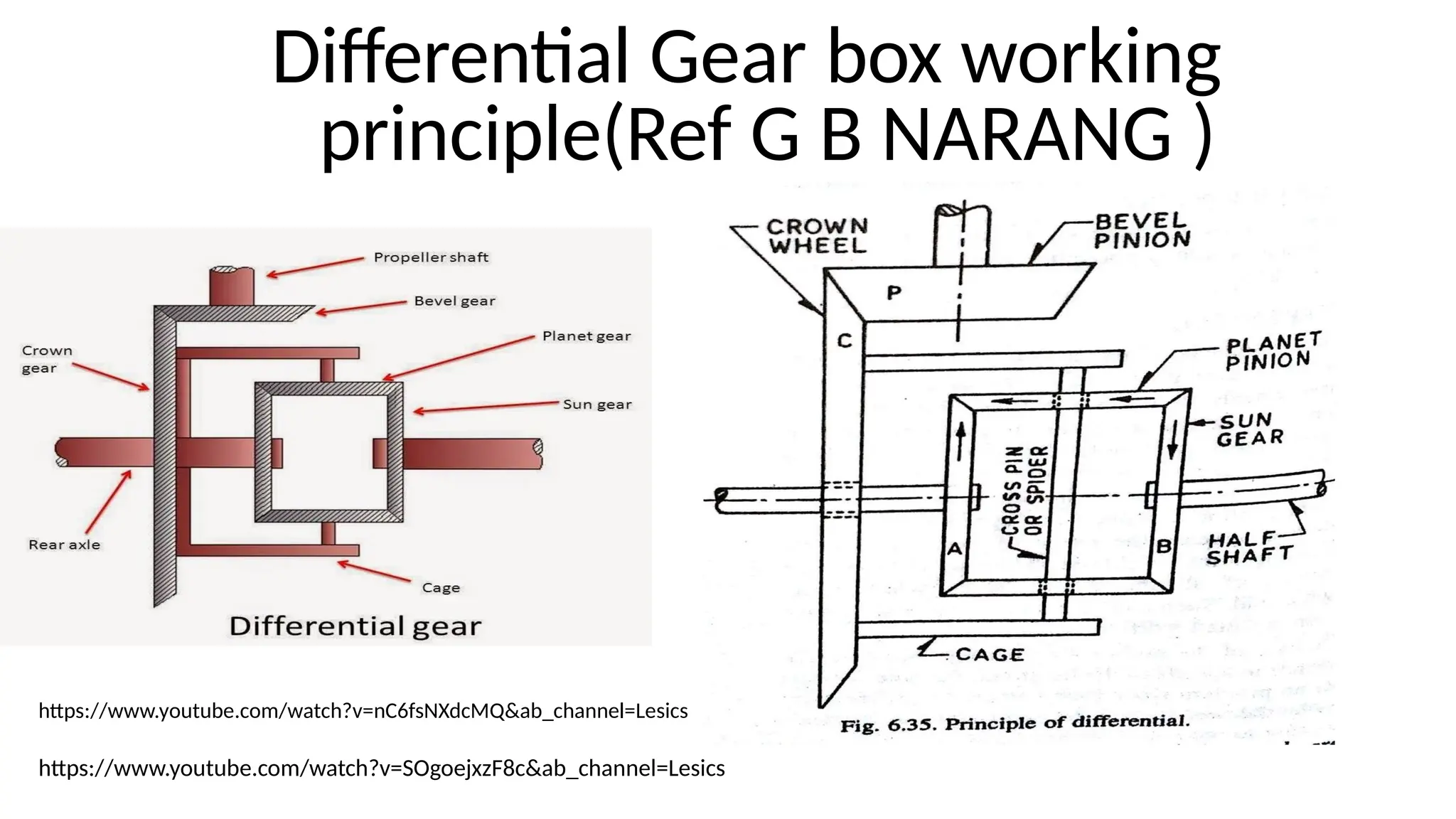

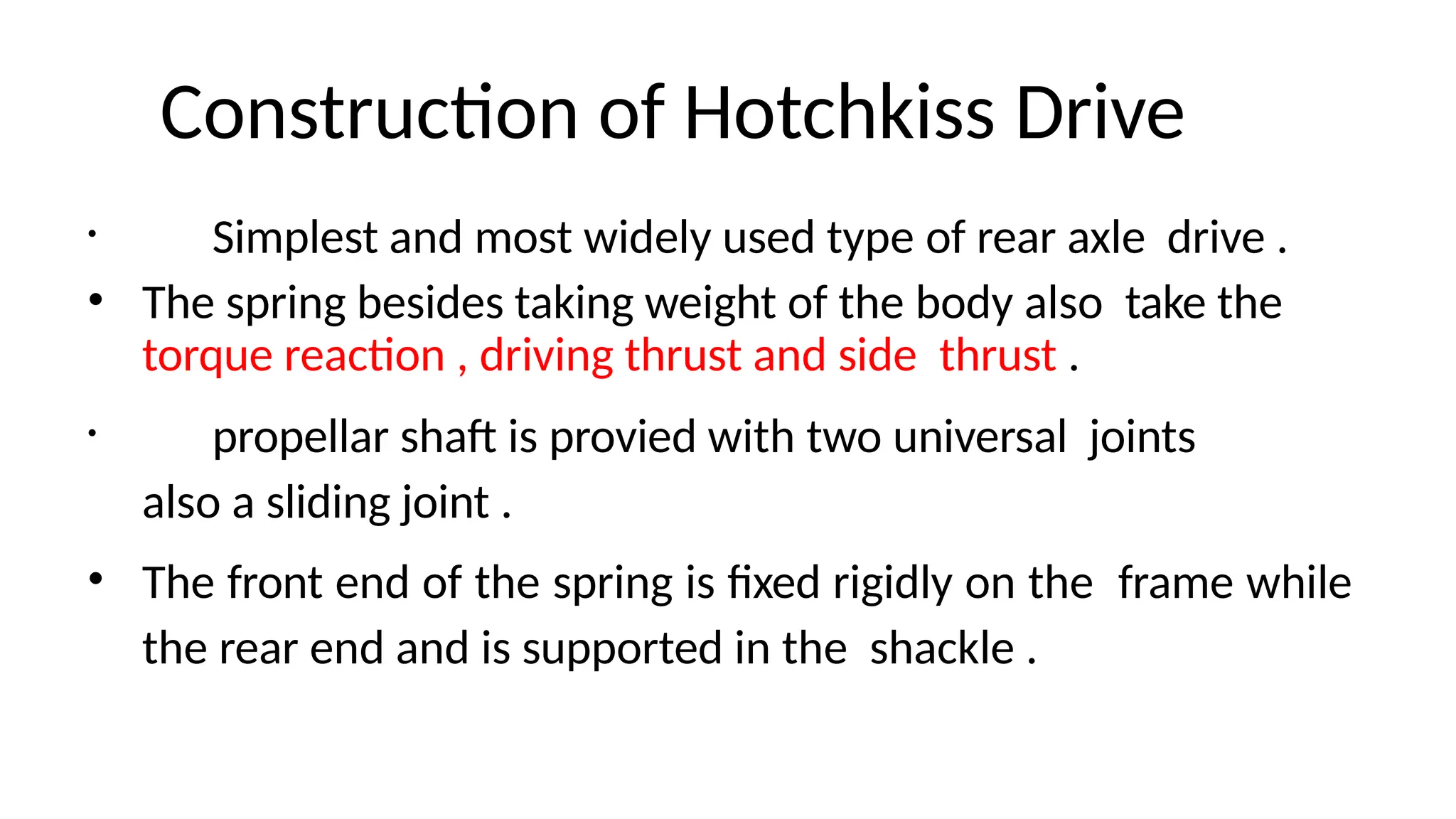

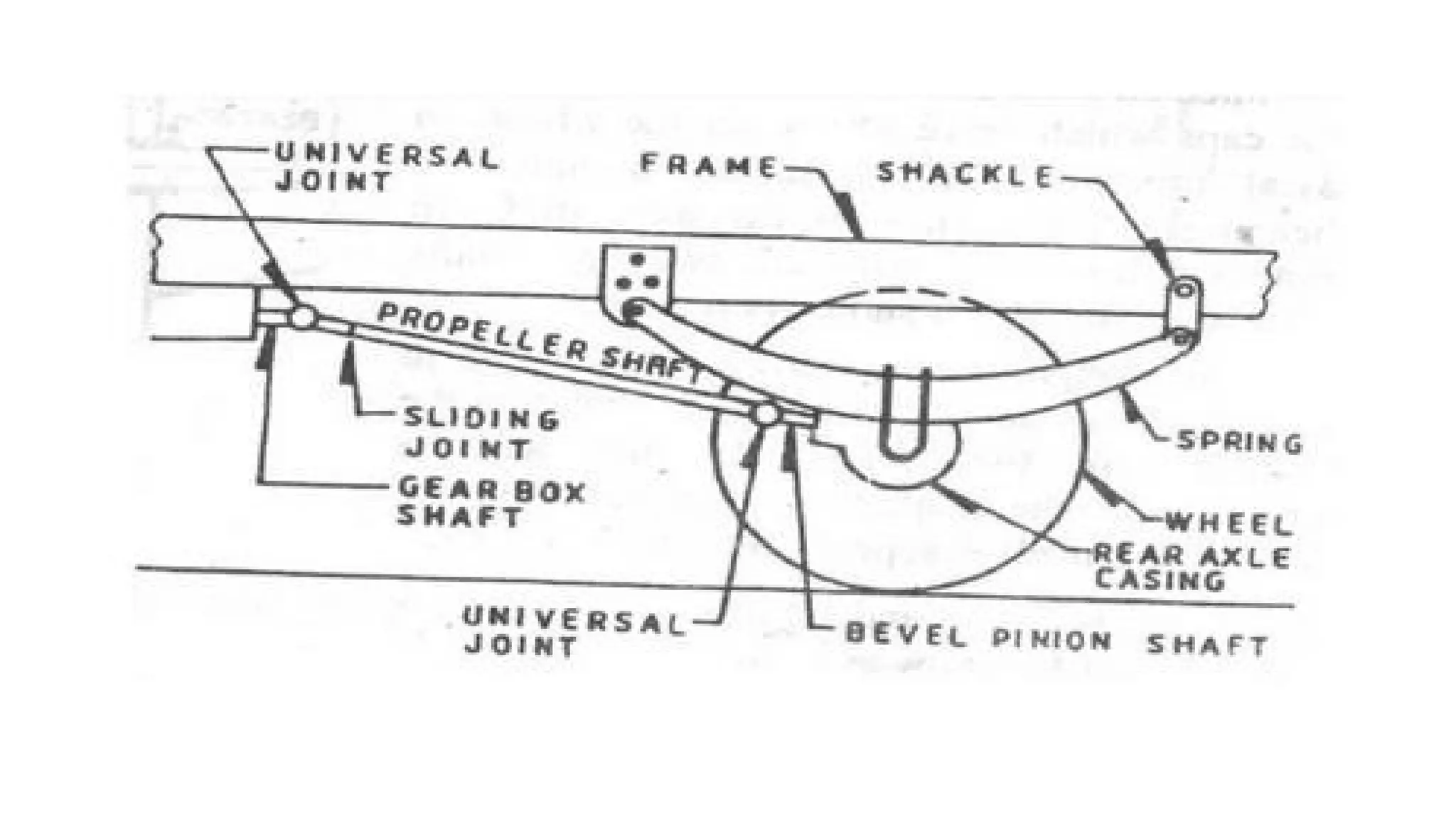

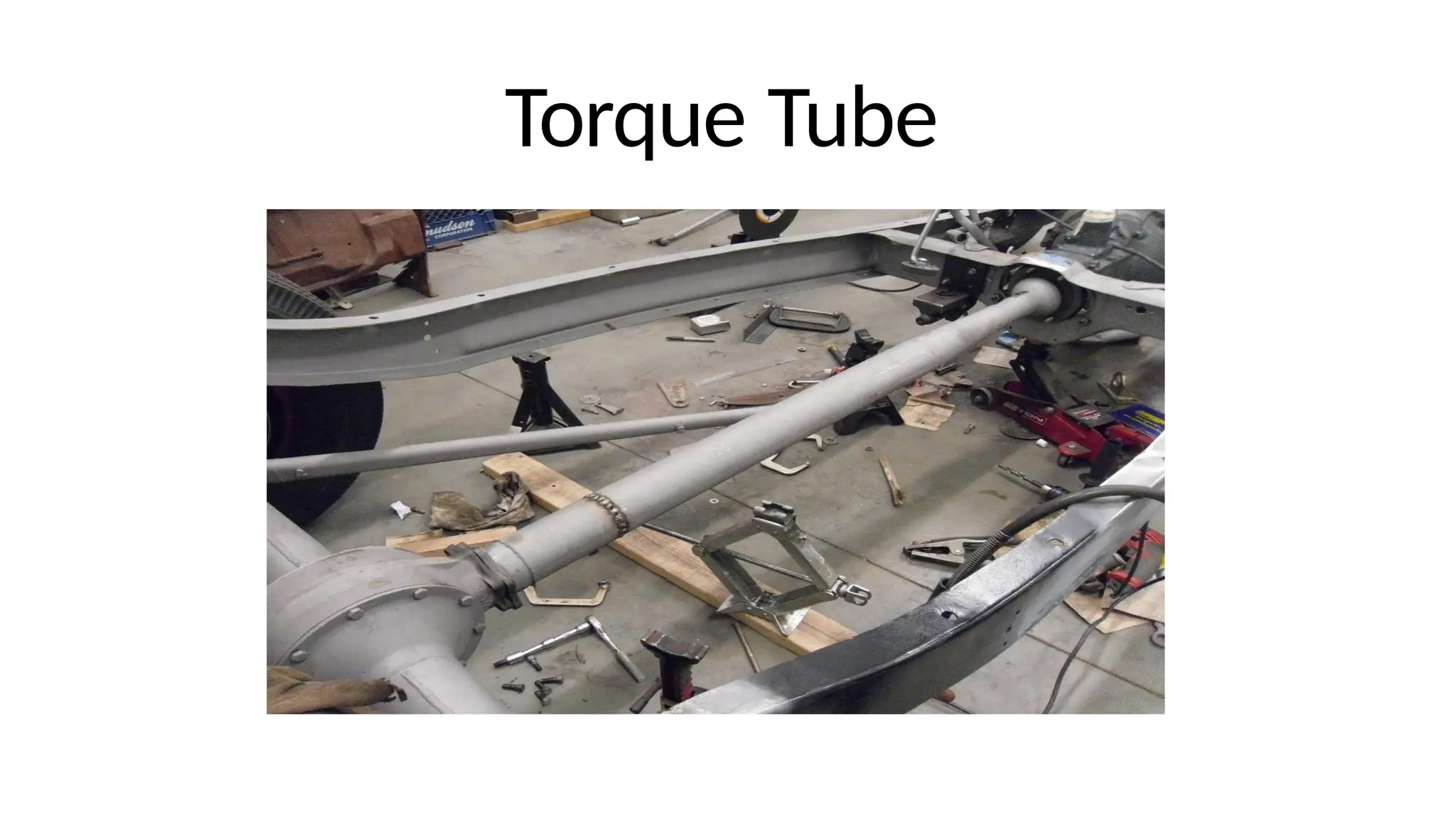

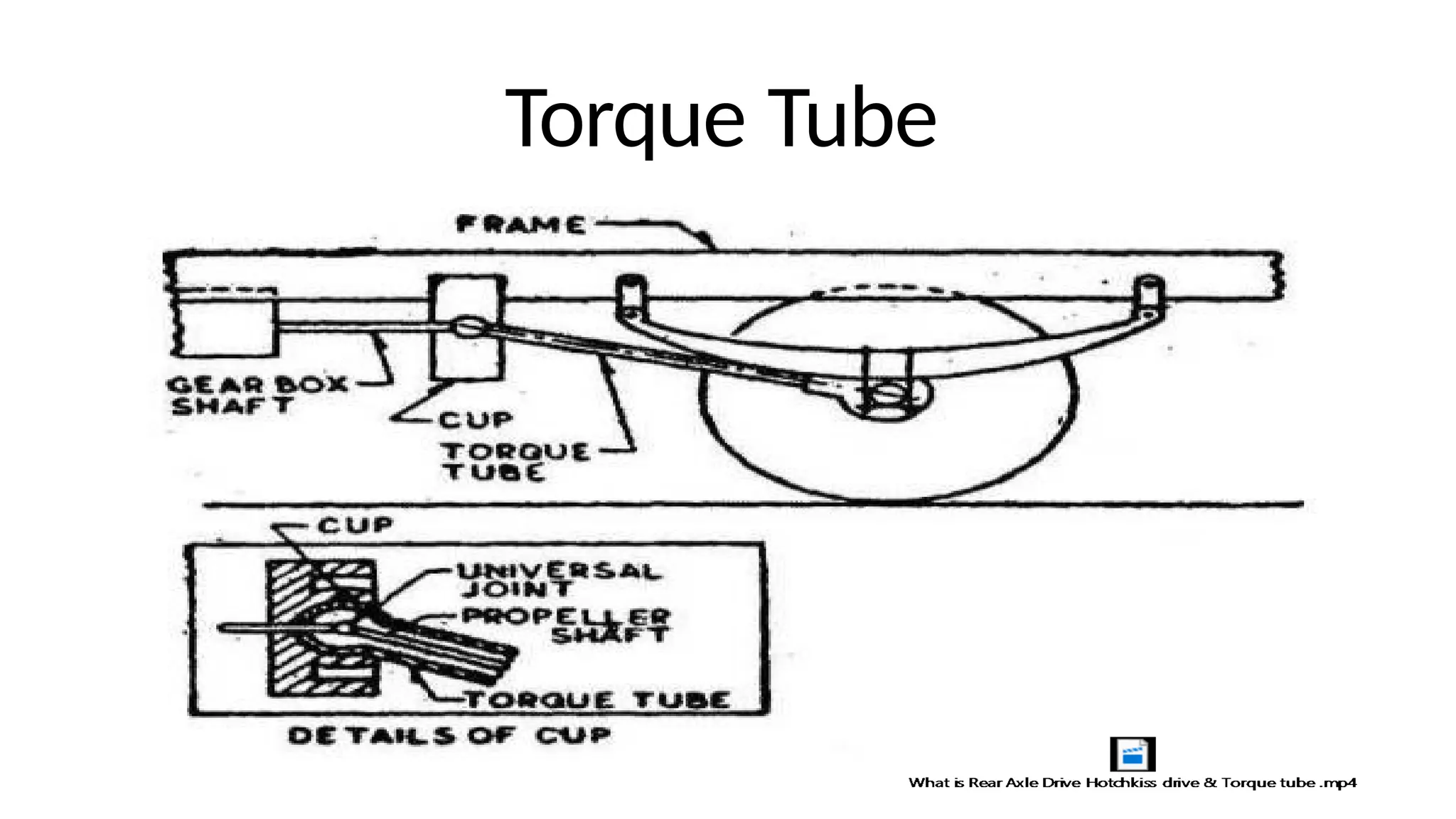

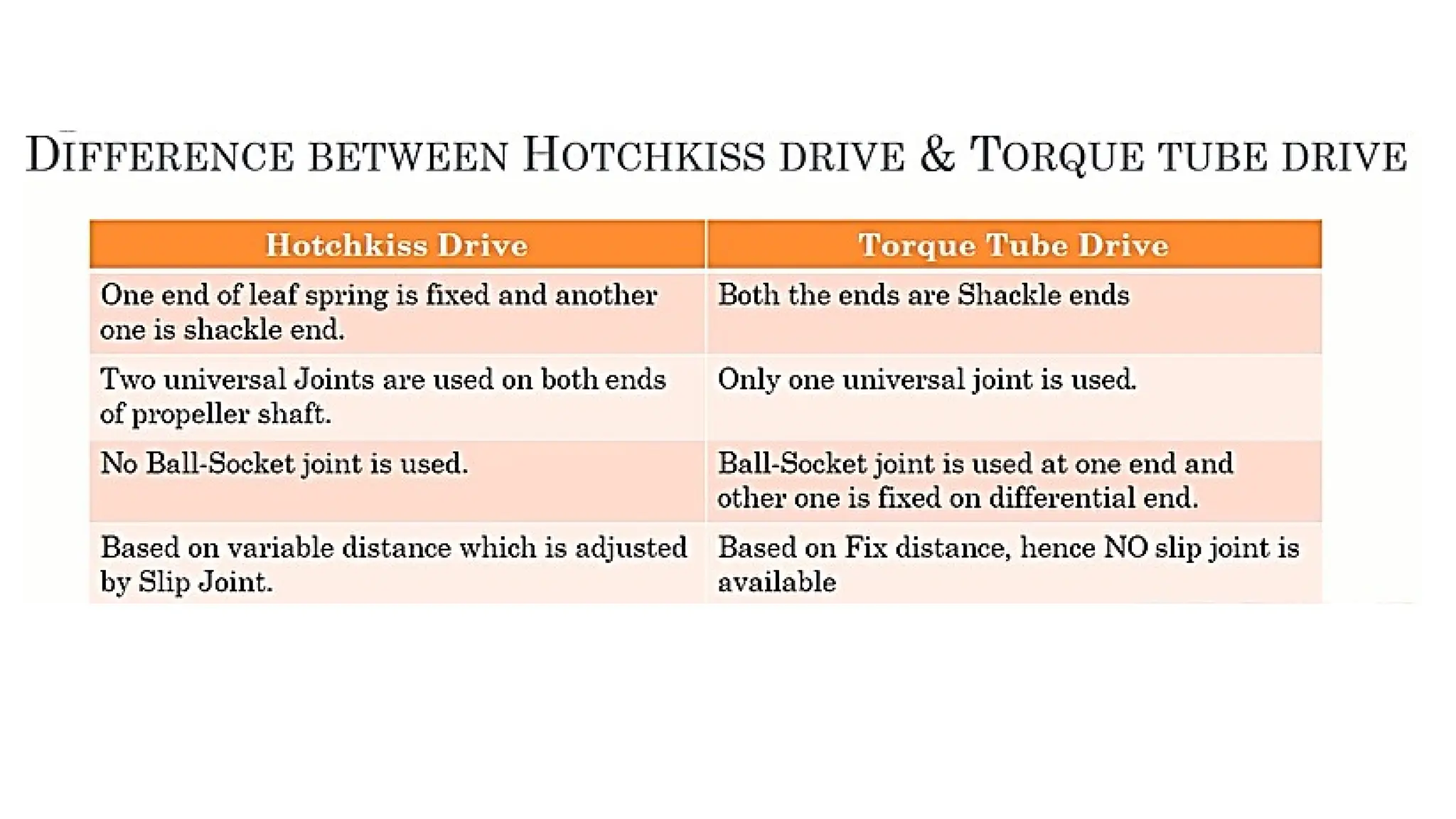

The document provides an overview of overdrive systems in vehicles, explaining its function as a mechanism that allows the propeller shaft to turn faster than the main transmission shaft, enhancing engine efficiency during high-speed operation. It details the construction of the overdrive, including its epicyclic gear train and the role of various components such as the universal joint, propeller shaft, and differential. Additionally, it highlights the Hotchkiss drive system, a historical method of power transmission used in front-engine, rear-wheel-drive cars.