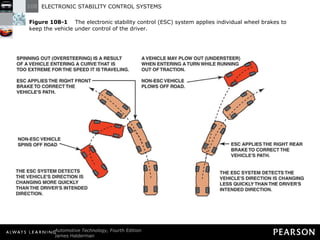

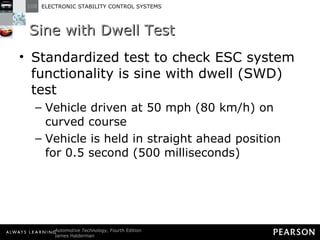

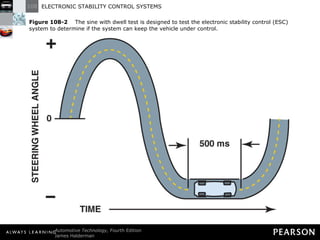

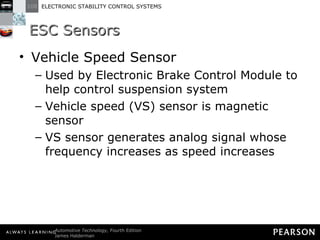

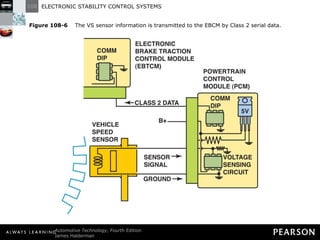

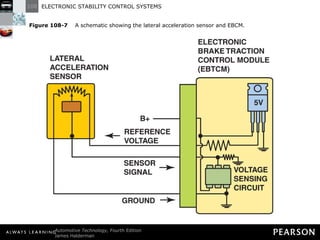

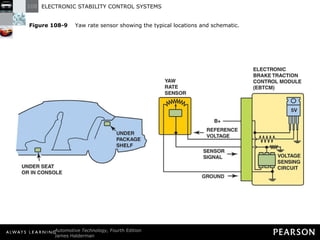

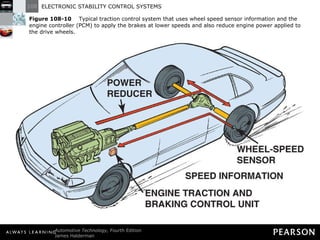

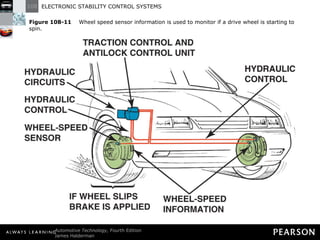

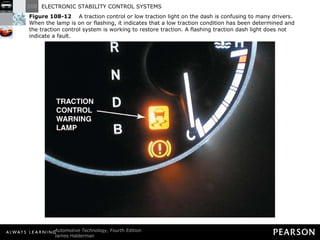

The document discusses electronic stability control (ESC) systems. ESC uses sensors and individual wheel braking to help drivers maintain control of their vehicle during maneuvers like sharp turns or on slippery roads. It works by applying brakes when it detects loss of traction or if the vehicle is not following the driver's intended path. Traction control is similar but focuses on preventing wheel spin during acceleration. Both systems use wheel speed, steering, lateral acceleration and yaw rate sensors along with anti-lock braking to keep the vehicle stable.