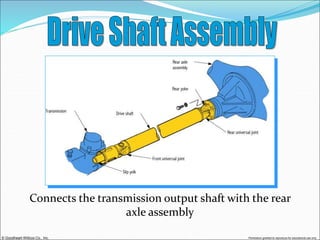

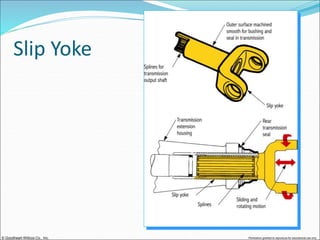

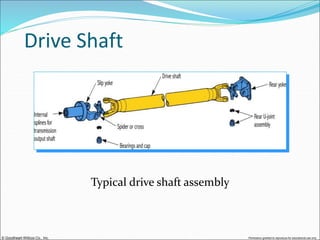

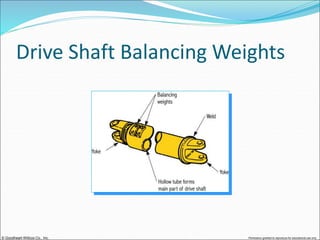

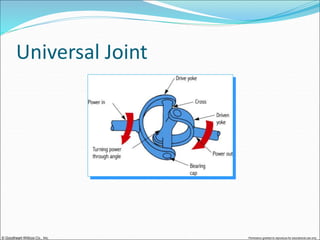

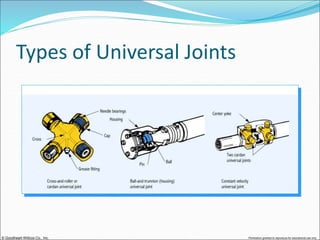

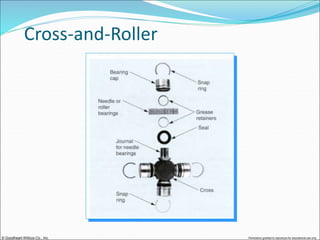

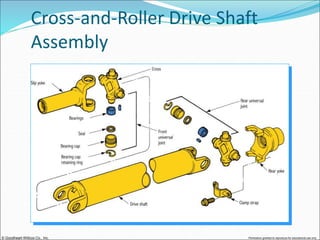

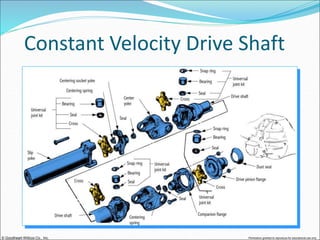

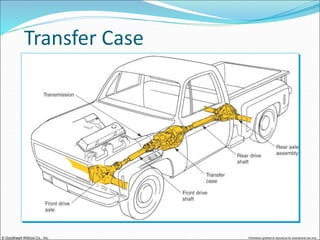

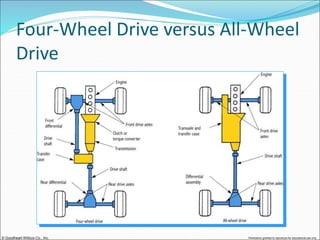

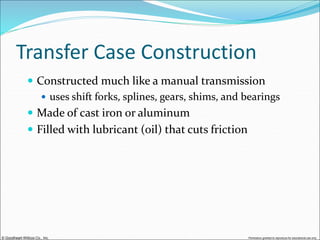

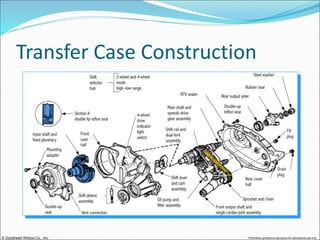

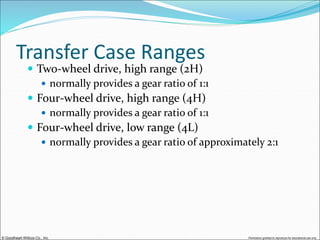

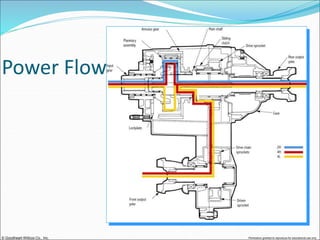

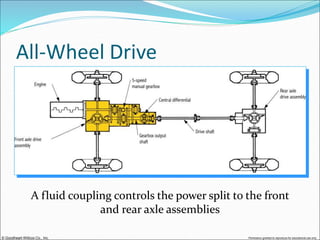

The drive shaft connects the transmission output shaft to the rear axle assembly. It consists of a slip yoke, universal joints, and drive shaft. The universal joints allow the drive shaft to flex and transfer power smoothly as the rear axle moves up and down. The drive shaft must be balanced to reduce vibration during high speeds. A transfer case splits power between front and rear axles for four-wheel drive vehicles. It has different ranges like 2H, 4H, and 4L to provide different gear ratios for various terrain.