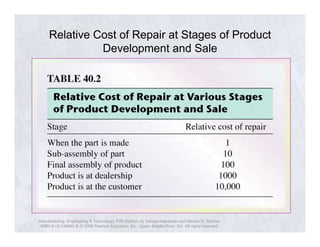

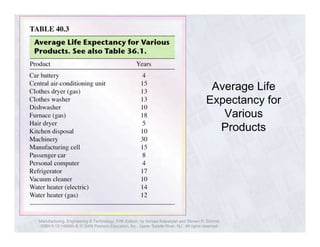

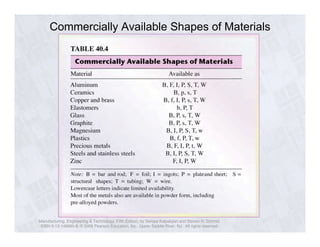

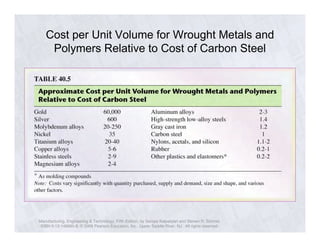

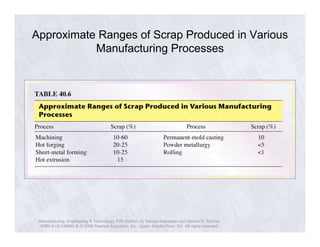

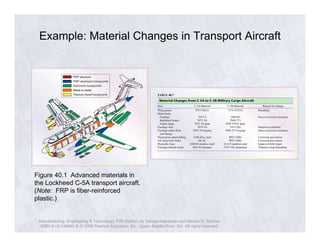

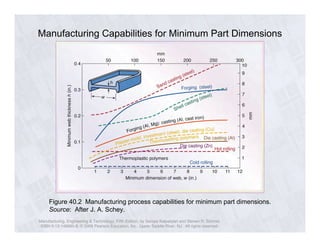

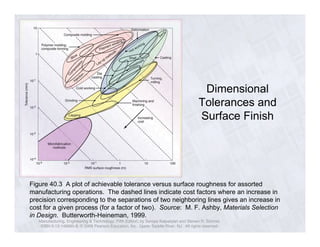

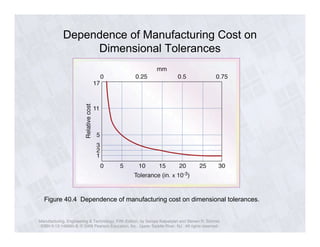

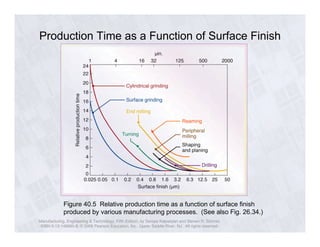

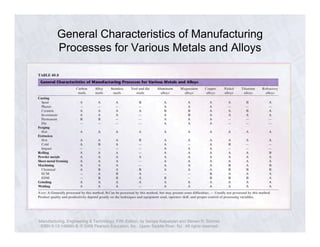

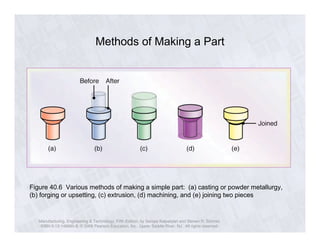

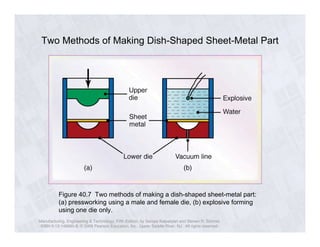

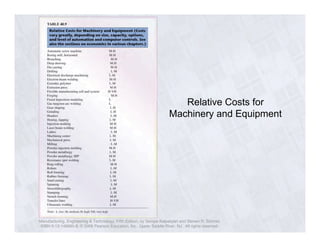

The document contains summaries and figures from the textbook "Manufacturing, Engineering & Technology, Fifth Edition" relating to product design and process selection. It includes information on the relative costs of repair at different product stages, average product lifespans, commercially available material shapes, manufacturing capabilities, tolerances, surface finishes, production times, and costs for different manufacturing processes and machinery.