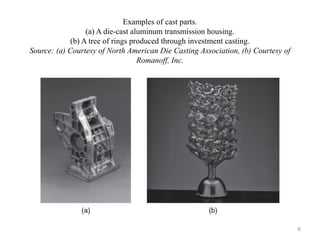

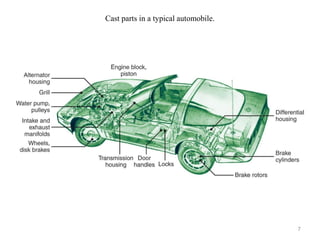

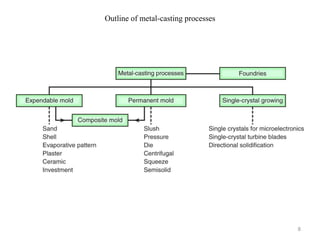

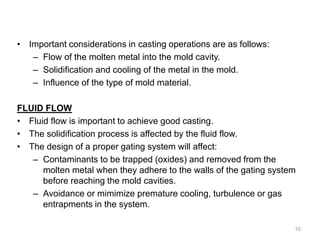

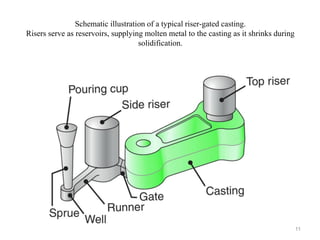

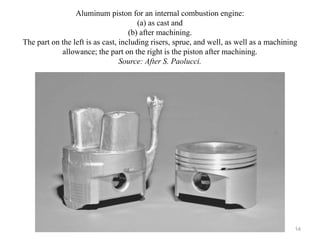

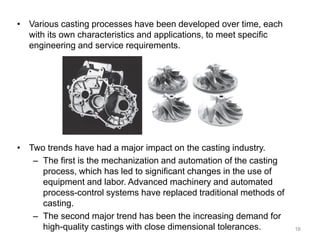

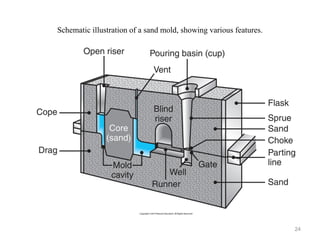

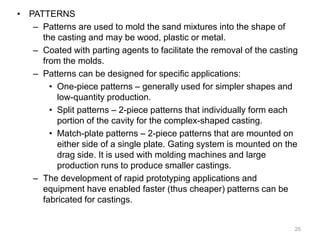

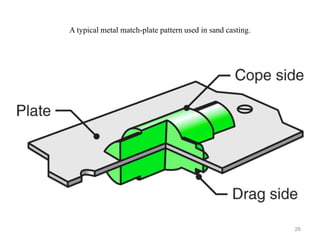

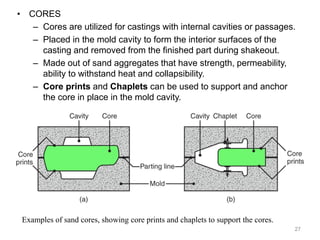

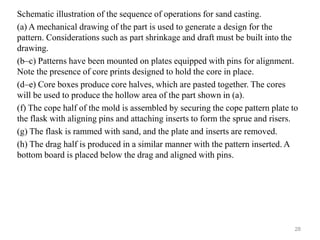

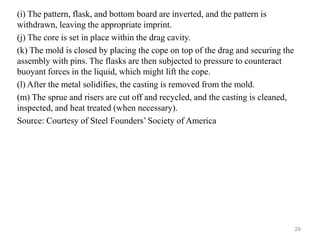

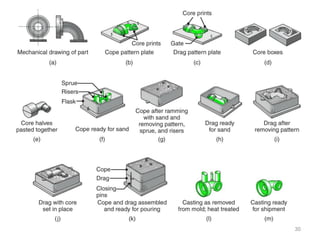

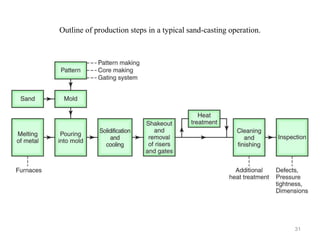

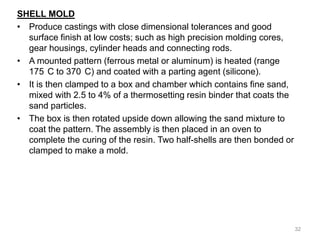

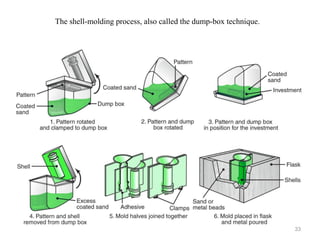

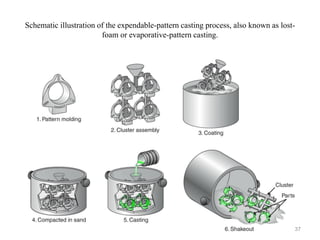

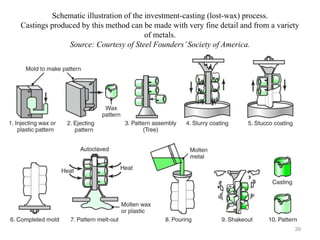

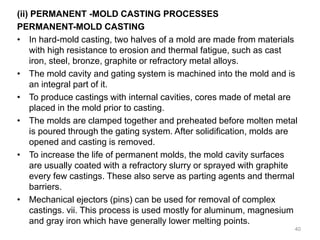

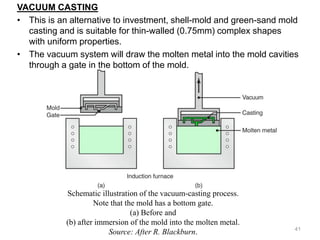

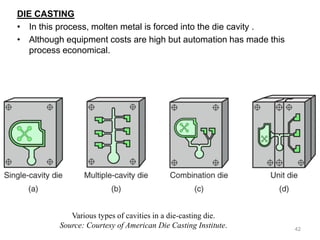

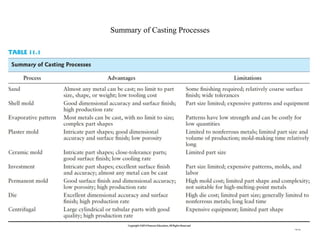

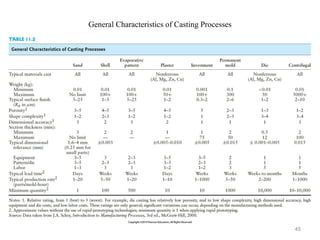

This document provides an overview of casting processes and techniques. It begins with learning outcomes and syllabus details for a workshop technology course. The document then covers fundamentals of metal casting including fluid flow, fluidity, heat transfer and solidification. It discusses various casting processes like sand casting, shell mold casting, plaster mold casting, permanent mold casting, investment casting, lost foam casting and vacuum casting. For each process, it provides details on mold materials, production steps, advantages and applications. Diagrams and figures are included to illustrate key aspects of different casting methods.

![EME3016

WORKSHOP TECHNOLOGY

TRIMESTER2 (2013/2014)

CHAPTER 2: Casting

[TEXTBOOK CHAPTER 10 & 11]

1](https://image.slidesharecdn.com/c2casting-150507160759-lva1-app6892/75/C2-casting-1-2048.jpg)