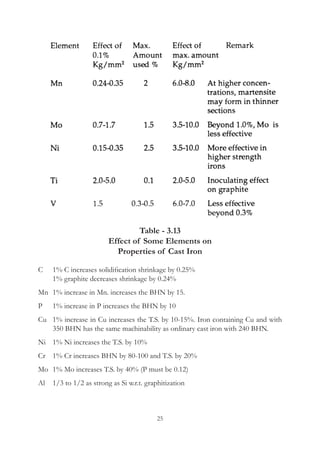

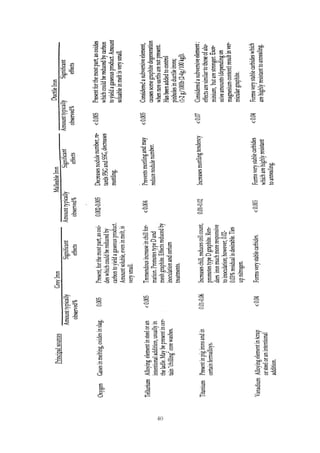

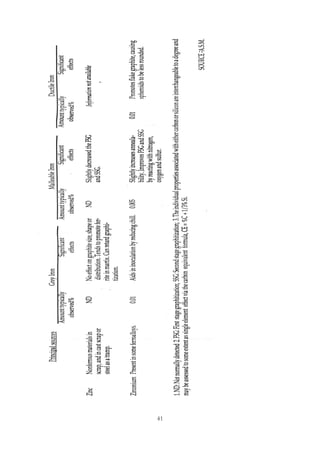

This document provides an overview of alloying elements in cast iron and their effects. Key points:

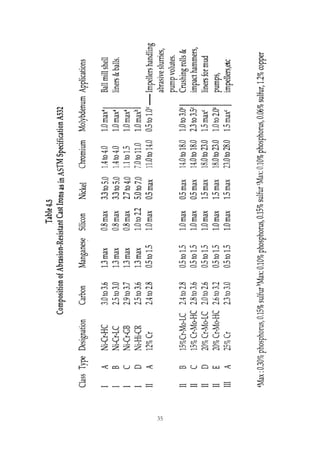

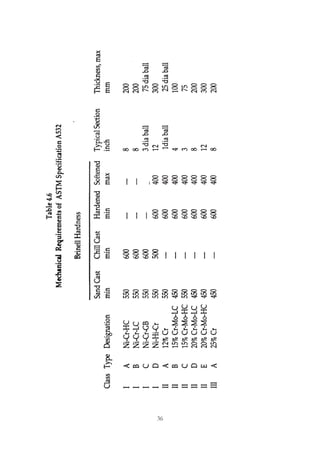

1. Common alloying elements added to cast iron include copper, nickel, chromium, molybdenum, and vanadium. These improve properties like tensile strength, hardness, wear resistance, and creep resistance.

2. Optimal levels are around 1% copper, 1% nickel, 0.4% chromium, 0.5% molybdenum, and 0.2% vanadium. Alloy combinations can have synergistic effects.

3. Nodular irons are commonly alloyed with copper, nickel, molybdenum, and tin. Ferritic nodular

![99

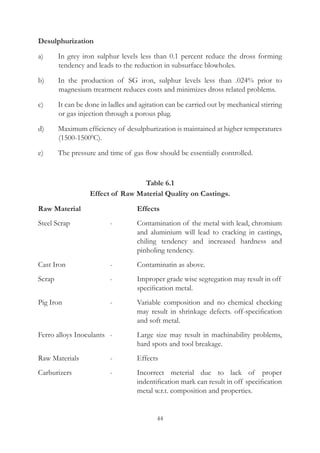

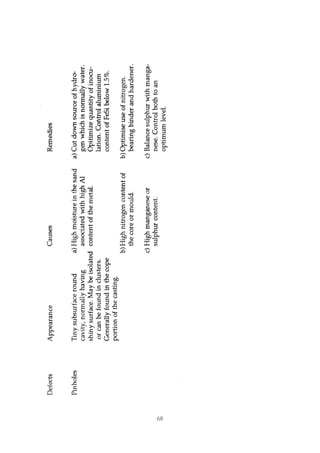

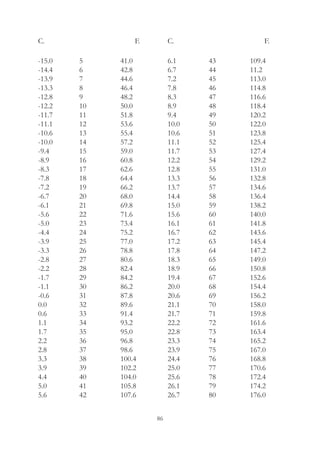

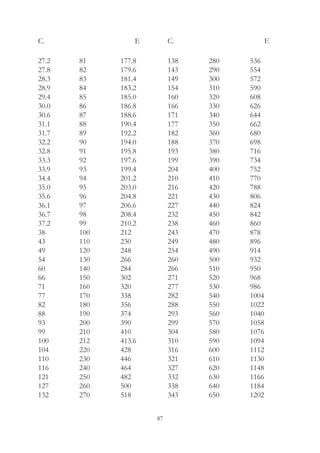

Their mutual relationship are as follows :

1 CC/100 g. of N2

= 0.00125%

= 12.5 ppm

1 CC/100 g. of H2

= 0.00009%

= 0.9 ppm

1 CC/100 g. of O2

= 0.00143%

= 14.3 ppm

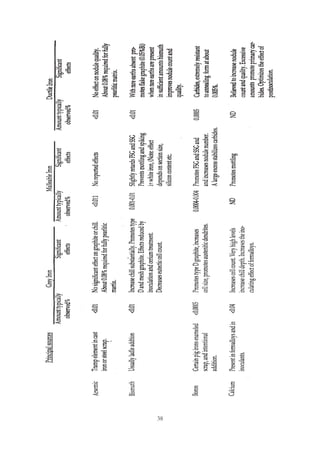

Solubility of gases in molten cast iron :

Nitrogen

Log [n%] = -100/T=0.86-0.06 [Si+S] -0.24 C

-0.15 P + 0.015 Mn + 0.03 Cr

Hydrogen

For the normal compositions and temperatures and at atmospheric pressure :

[H] CC/100g = 25 - 3.5 C - 2Si + 10 Mn - 3 Cr.

However, in hypereutectic cast irons, carbon increases the solubility of H2

due to

adsorption on graphite.

Osygen

Log [%0] = -2975/T - 1.06 -log[%C] + 0.19 [%C]

- 0.5 log [% Si]

Like in the case of hydrogen, the solubility of oxygen in hypereutectic irons also

increases due to adsorption.](https://image.slidesharecdn.com/castiron-210805043635/85/Cast-iron-99-320.jpg)