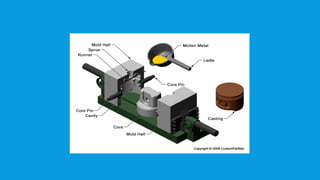

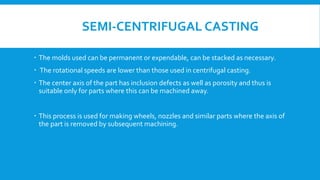

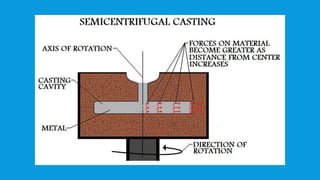

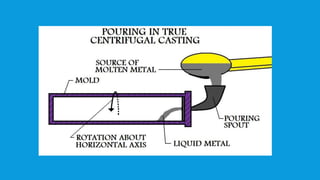

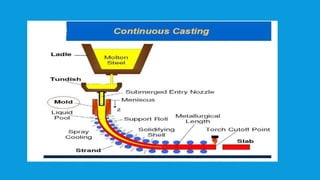

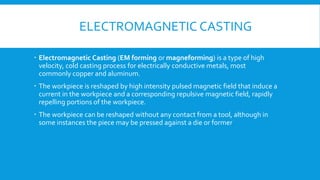

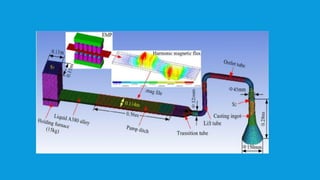

The document provides an overview of various casting processes used in manufacturing, emphasizing techniques like permanent mold casting, die casting, squeeze casting, and centrifugal casting. It discusses the characteristics, typical applications, and advantages of each method, including considerations such as tolerances, part sizes, and material types. Additionally, it covers newer processes like continuous casting and electromagnetic casting, highlighting their specific uses and benefits in producing intricate and defect-free parts.