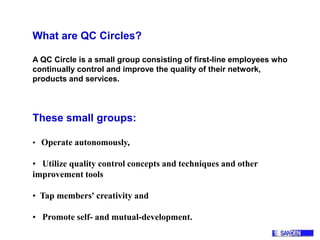

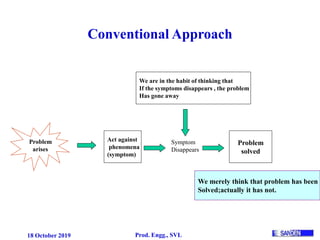

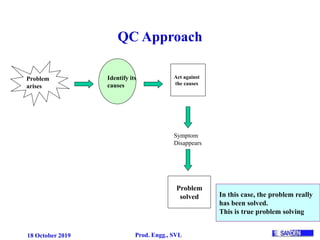

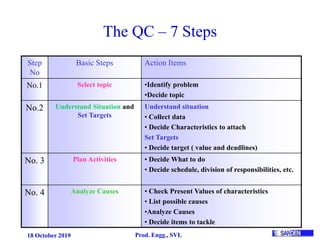

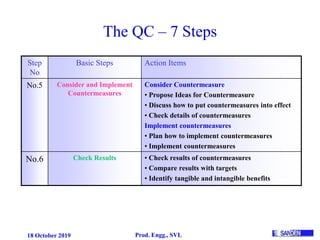

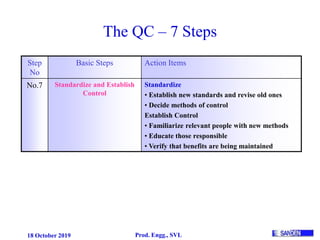

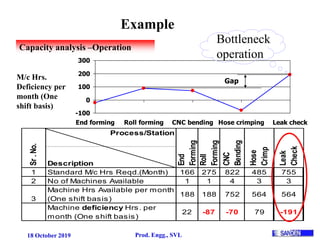

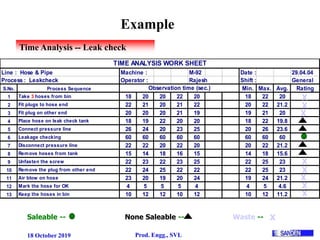

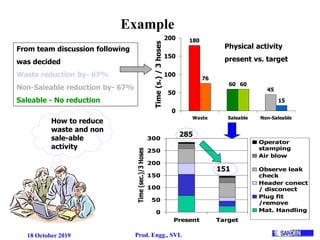

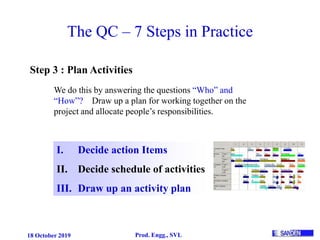

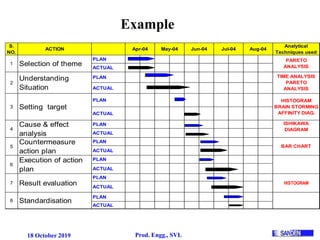

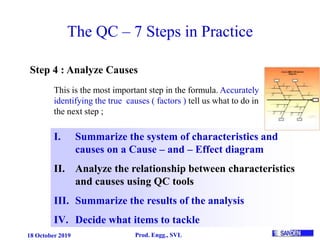

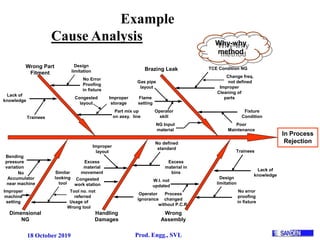

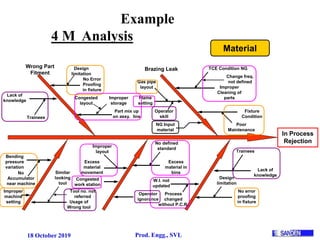

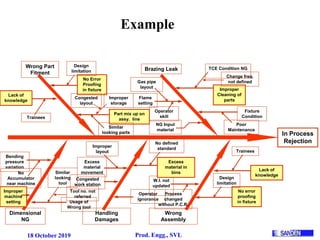

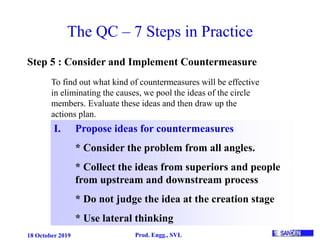

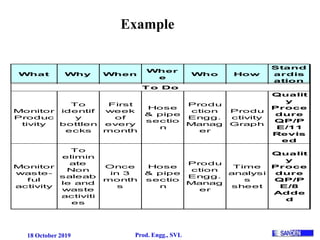

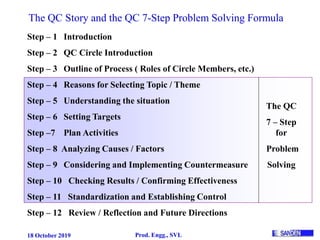

The document discusses quality control (QC) circles and the seven-step problem solving approach. It begins by defining QC circles as small groups of frontline employees who work to continually improve quality. It then outlines the seven steps of the problem solving approach: 1) select topic, 2) understand situation and set targets, 3) plan activities, 4) analyze causes, 5) consider and implement countermeasures, 6) check results, and 7) standardize and establish control. The document provides examples and details for applying each step of the seven-step approach to problem solving.