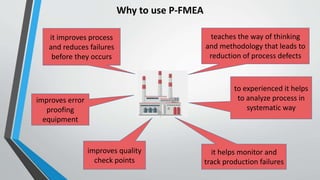

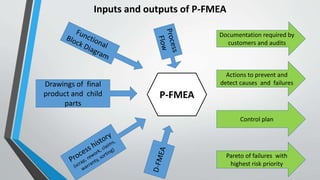

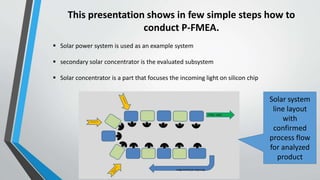

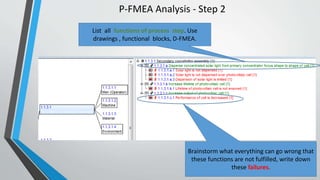

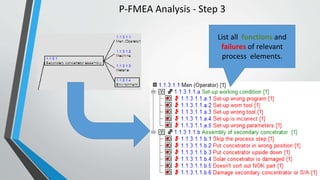

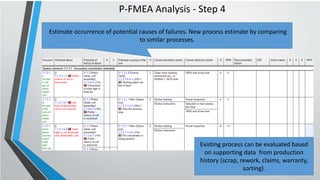

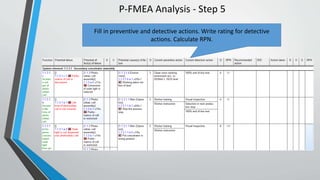

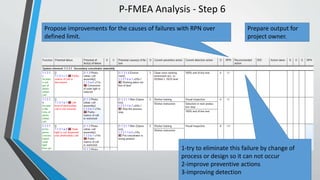

This document provides an overview of conducting a Process Failure Modes and Effects Analysis (P-FMEA). A P-FMEA helps improve processes, reduce failures, monitor production issues, improve quality checks, and teaches systematic analysis. The key steps include: 1) Listing all process steps and potential failures, 2) Estimating the likelihood of failures, 3) Recording prevention and detection actions, 4) Calculating a Risk Priority Number, and 5) Proposing improvements for high priority risks. An example of analyzing a solar concentrator subsystem in a solar power system is provided. The assumptions, inputs/outputs, and 6-step approach to conducting a P-FMEA are outlined.