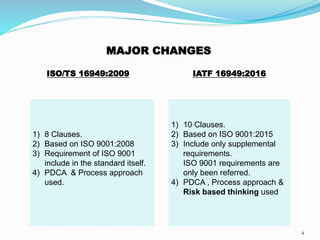

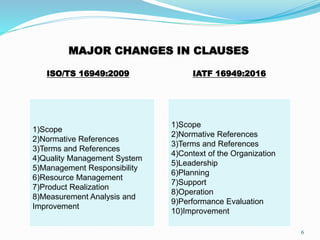

The document compares IATF 16949:2016 and ISO/TS 16949:2009 quality management standards. Some key differences include:

- IATF 16949:2016 has 8 clauses while ISO/TS 16949:2009 has 10 clauses.

- IATF 16949:2016 is based on ISO 9001:2008 and includes ISO 9001 requirements directly, while ISO/TS 16949:2009 is based on ISO 9001:2015 and only refers to ISO 9001 requirements.

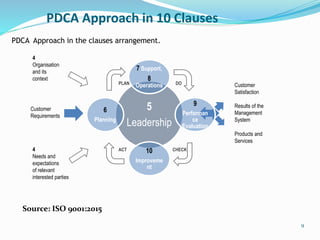

- IATF 16949:2016 uses a PDCA approach across its 8 clauses, while ISO/TS 16949:2009 uses PDCA, process approach, and risk-based thinking across its 10