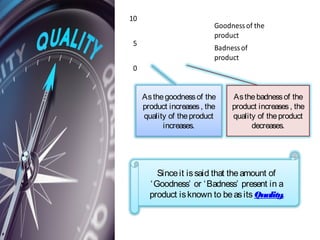

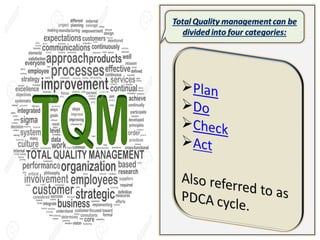

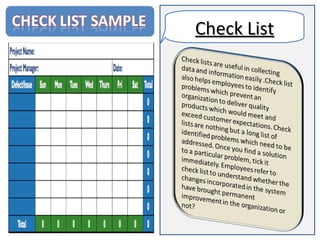

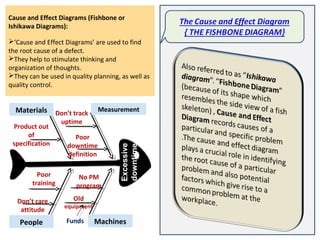

The document discusses total quality management. It explains that TQM aims to ensure long-term customer satisfaction and loyalty through continuous efforts by management and employees. Planning, doing, checking, and acting are the key phases of TQM. Planning involves identifying problems, researching causes, and finding solutions. Doing develops and implements strategies to address issues. Checking analyzes before and after data to measure results. Acting documents outcomes and prepares for future problems. TQM tools like cause-and-effect diagrams help organizations design high-quality products that meet customer needs. This leads to increased revenues, productivity, and reduced waste.