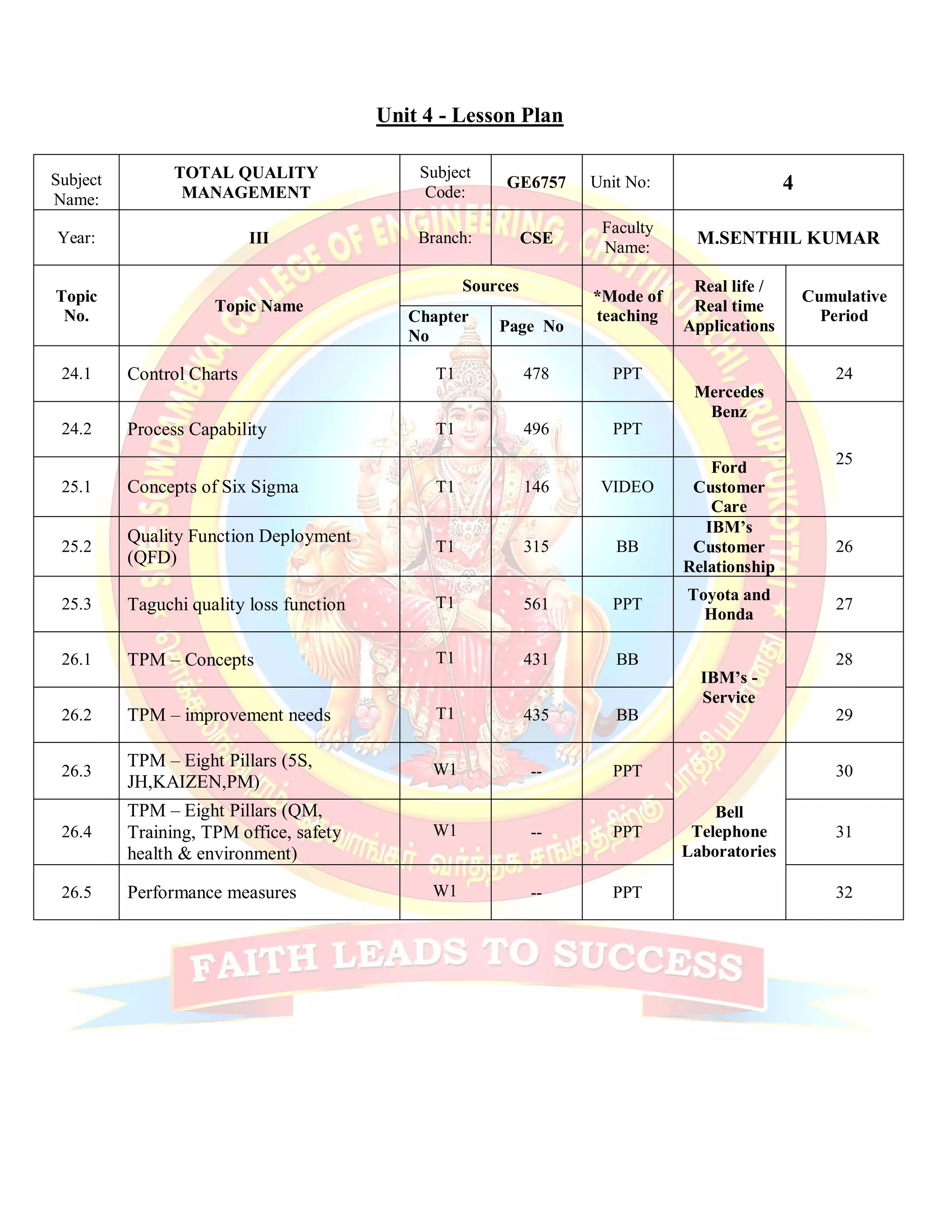

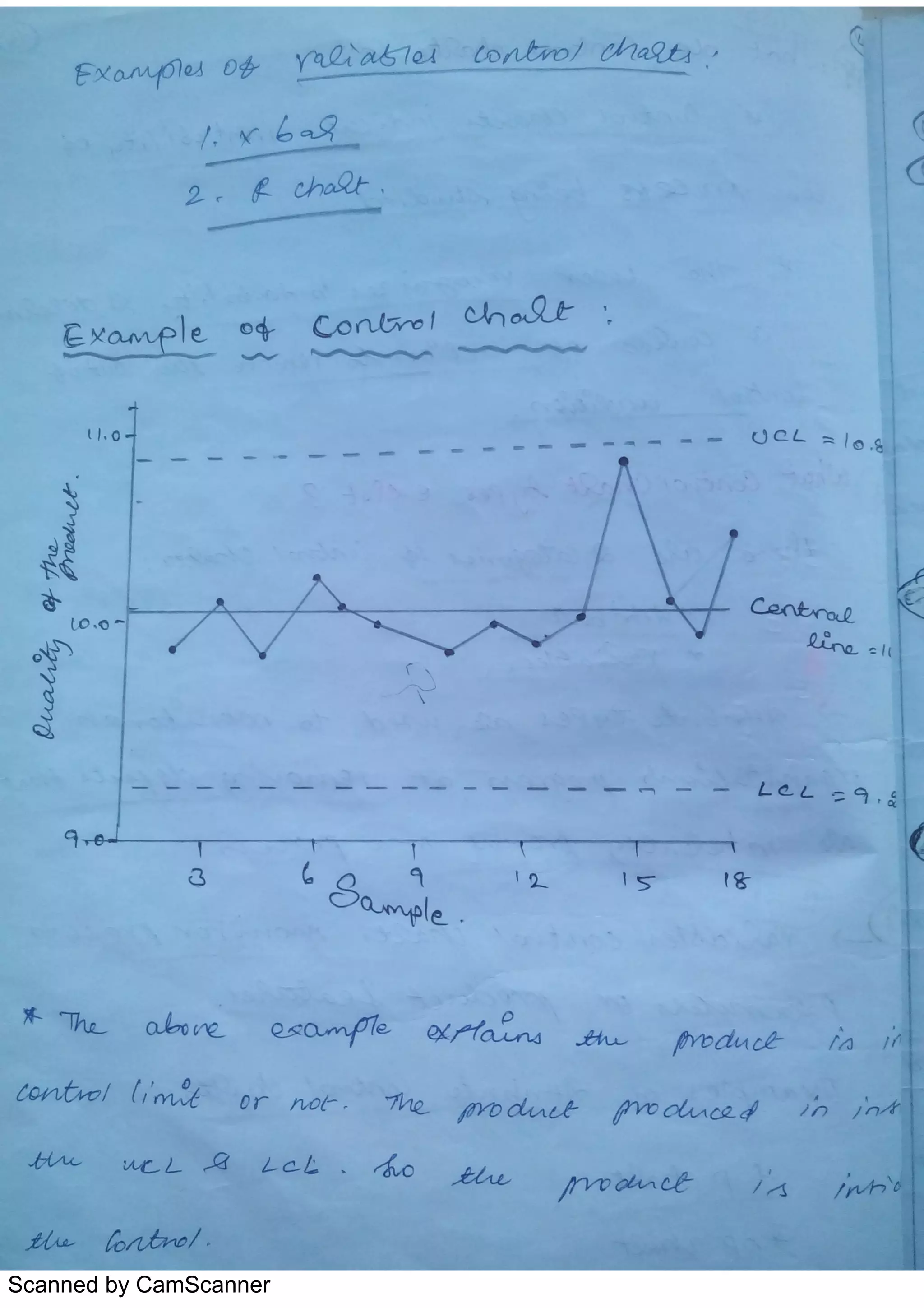

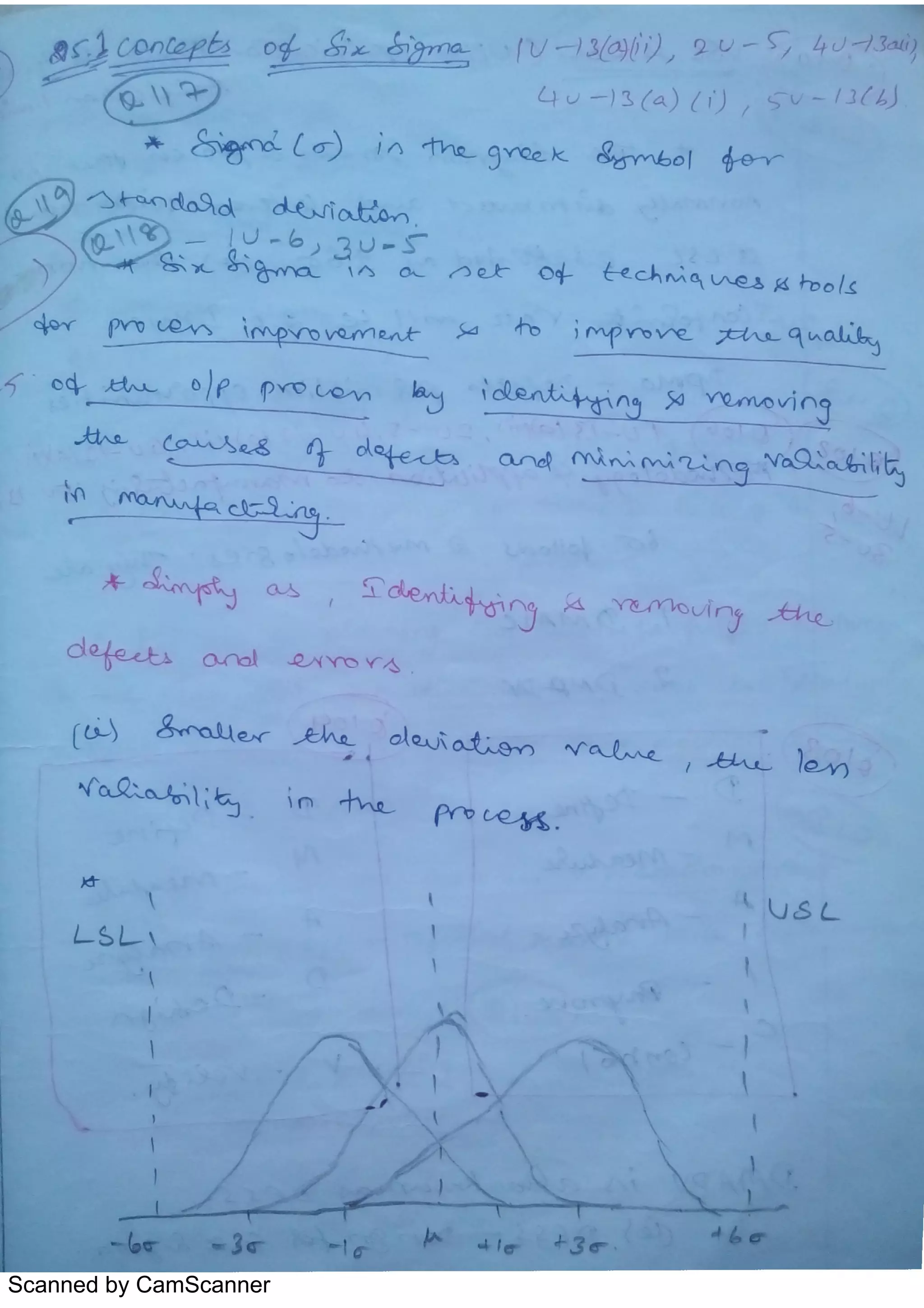

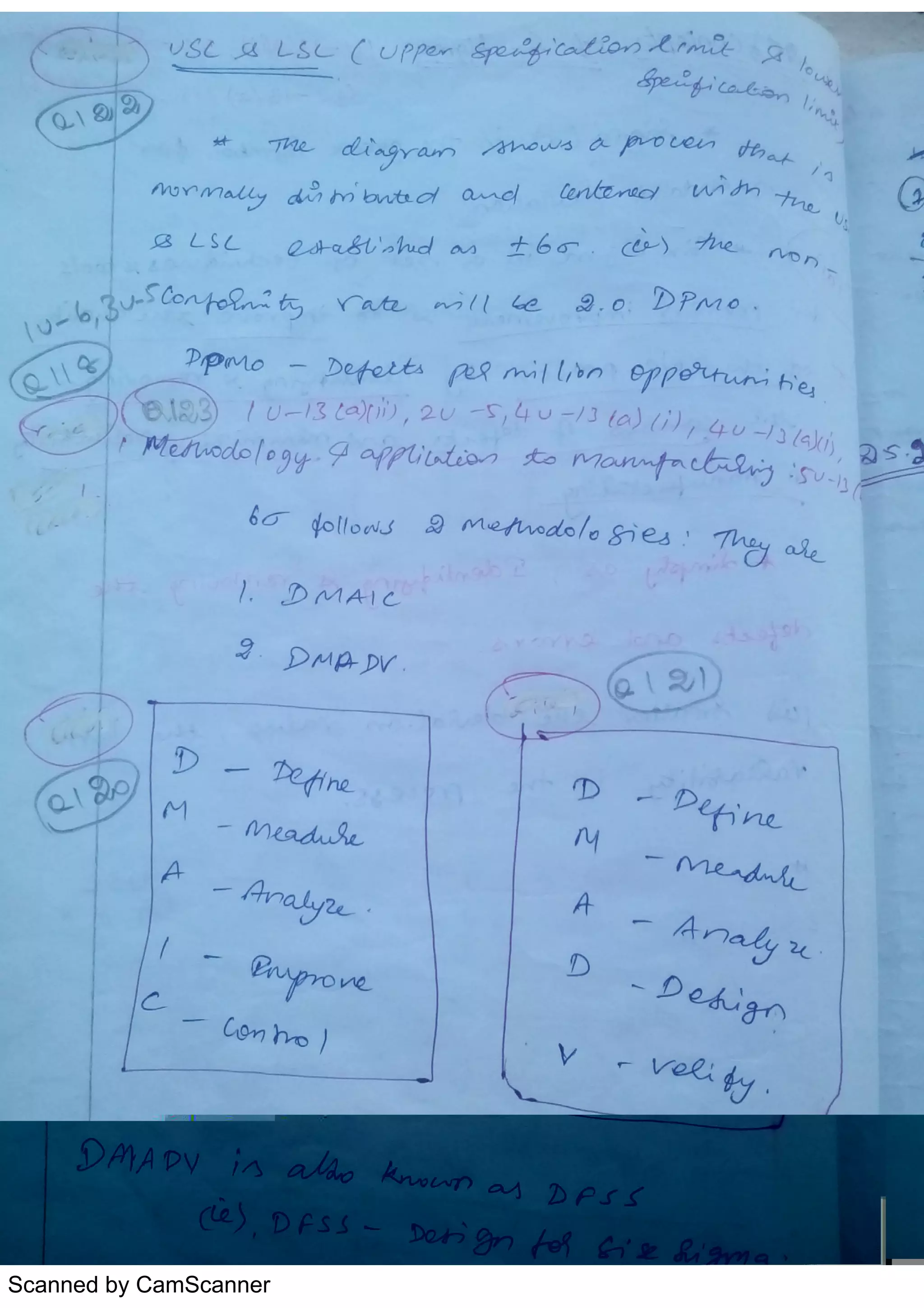

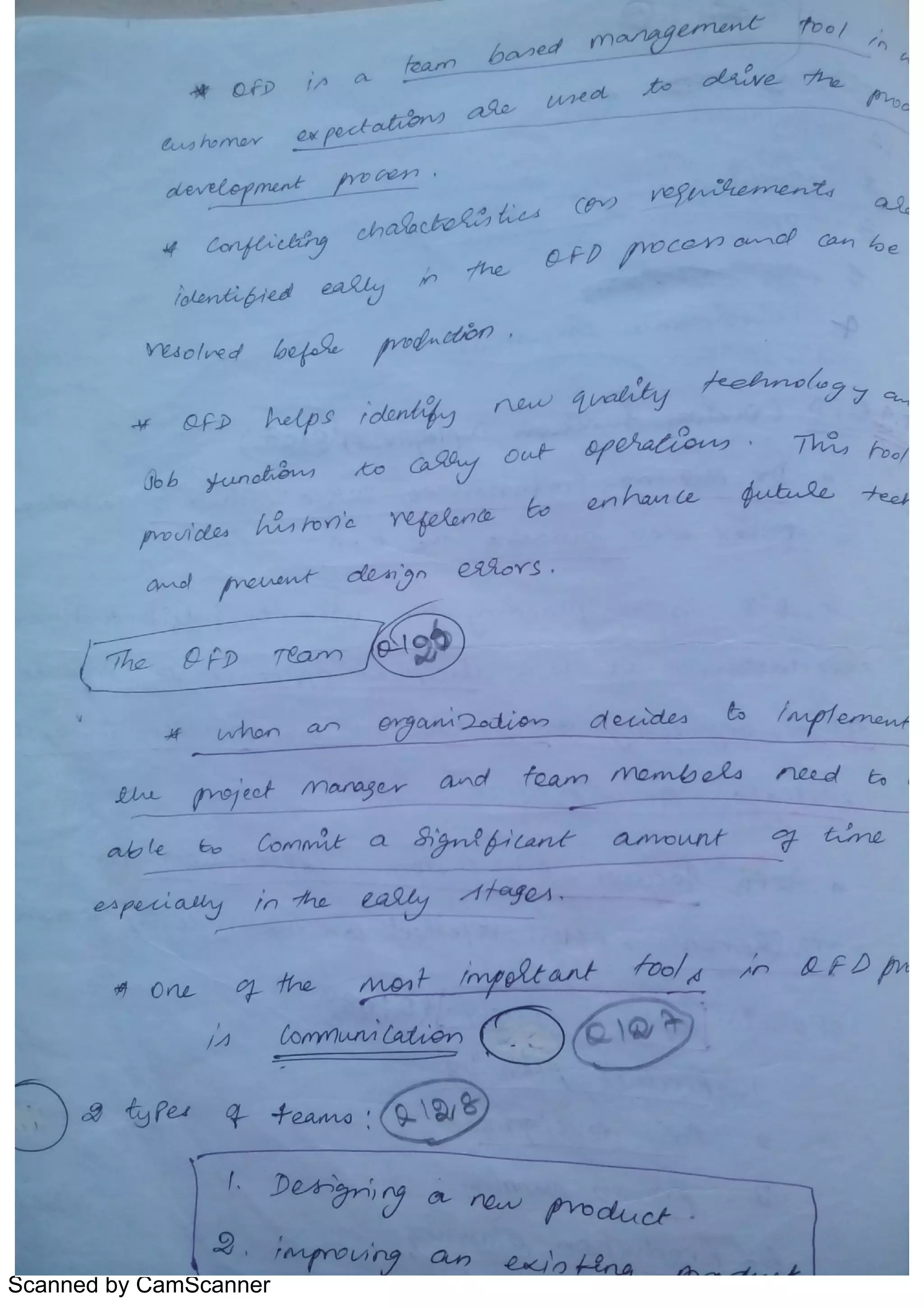

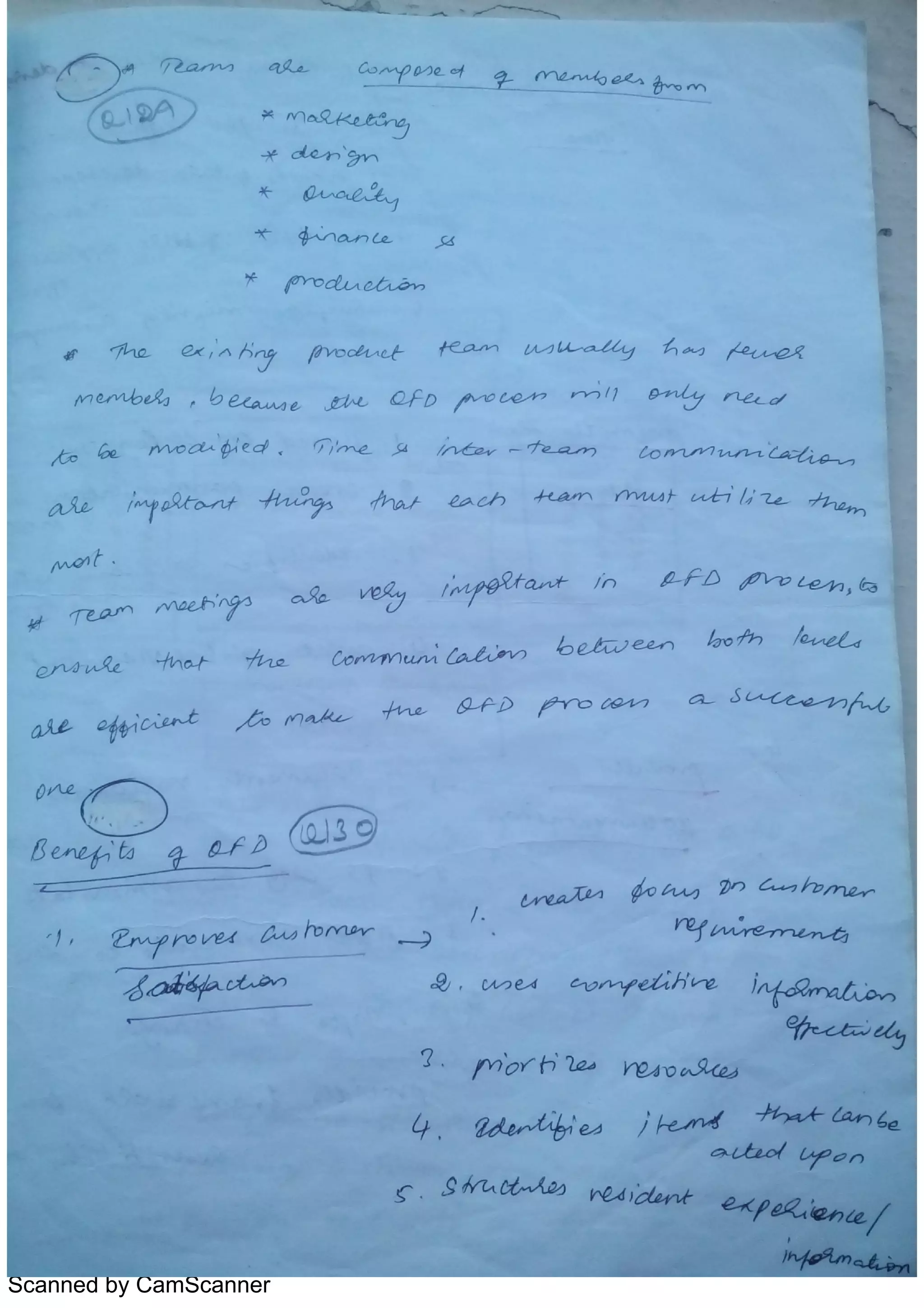

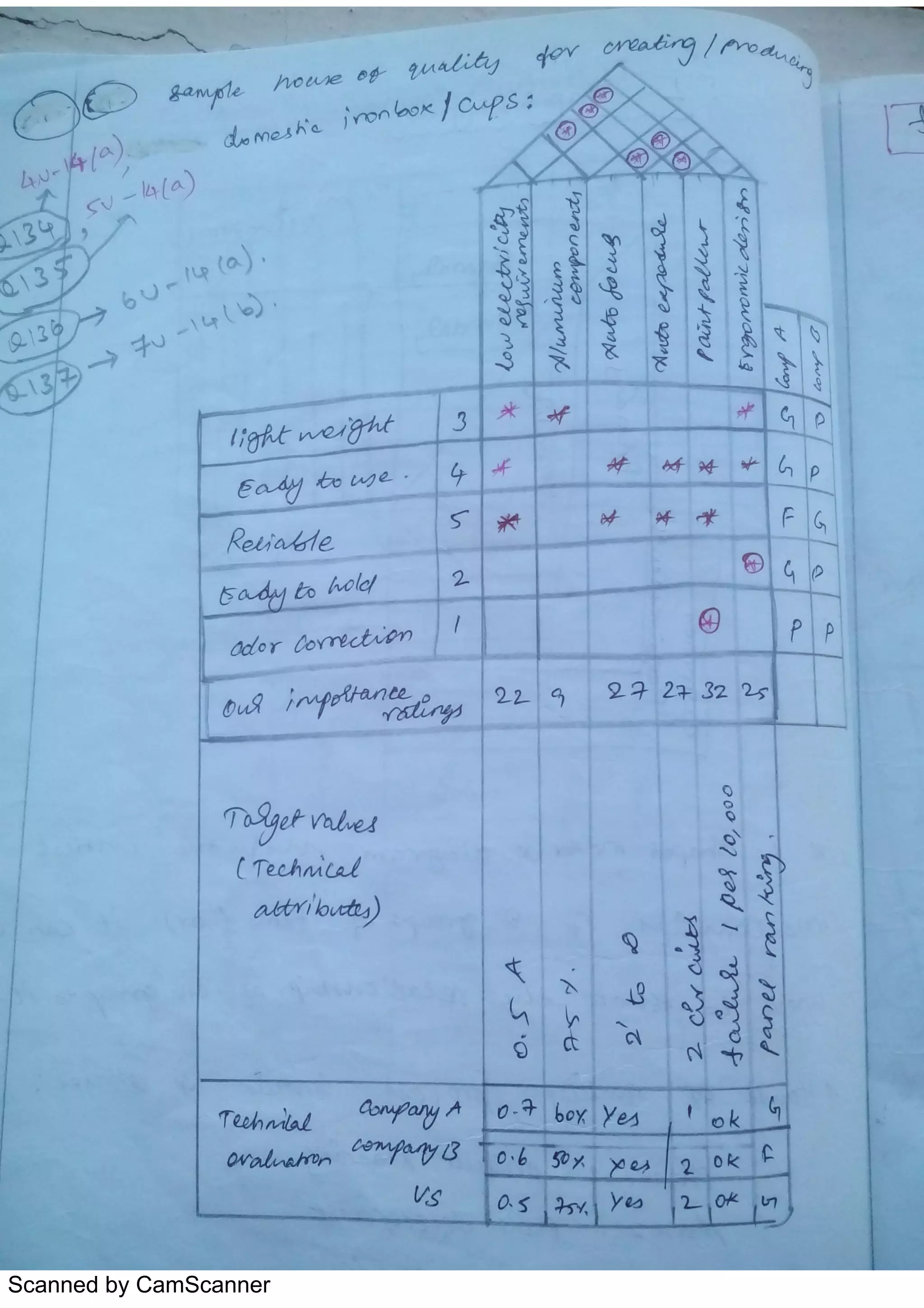

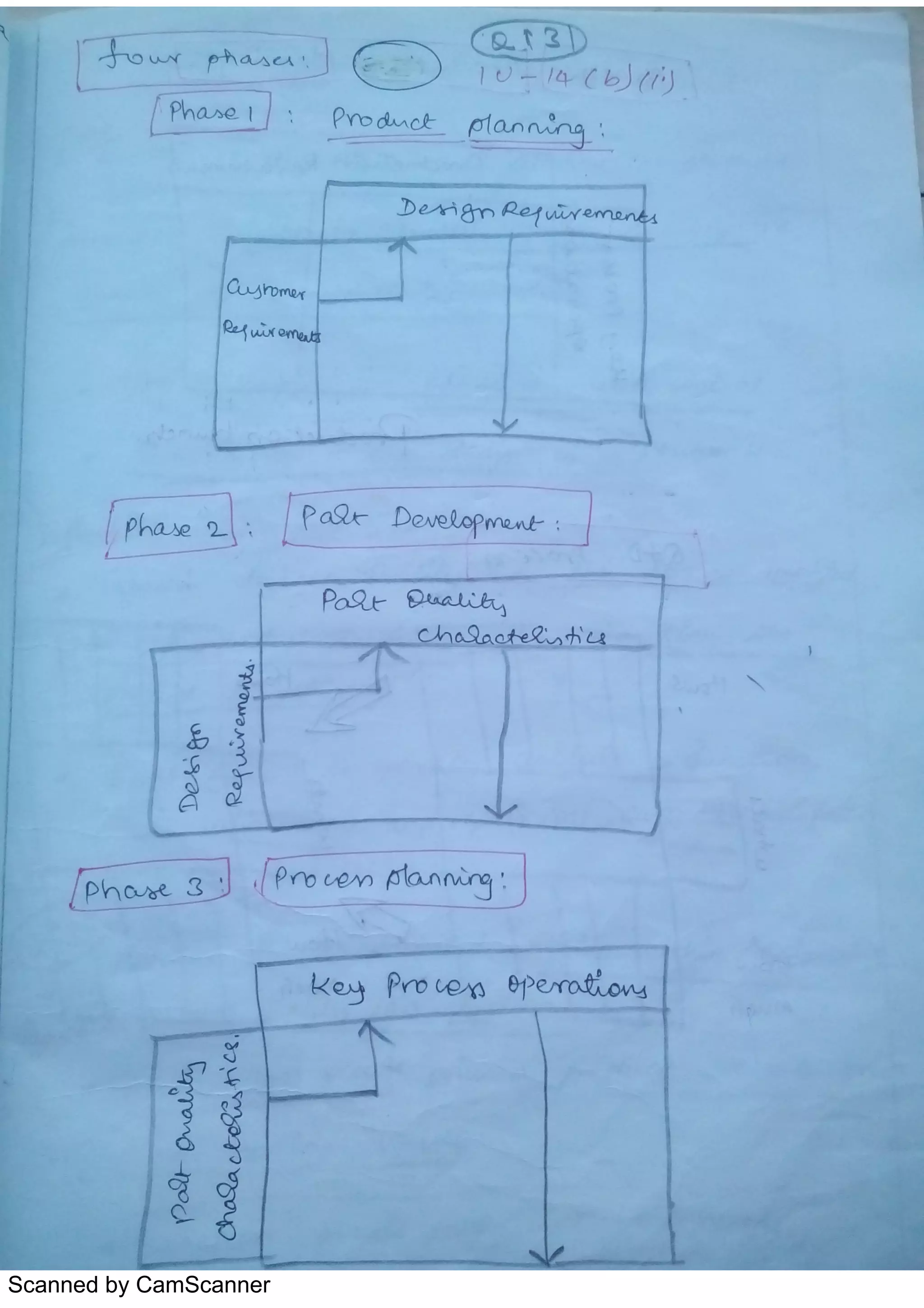

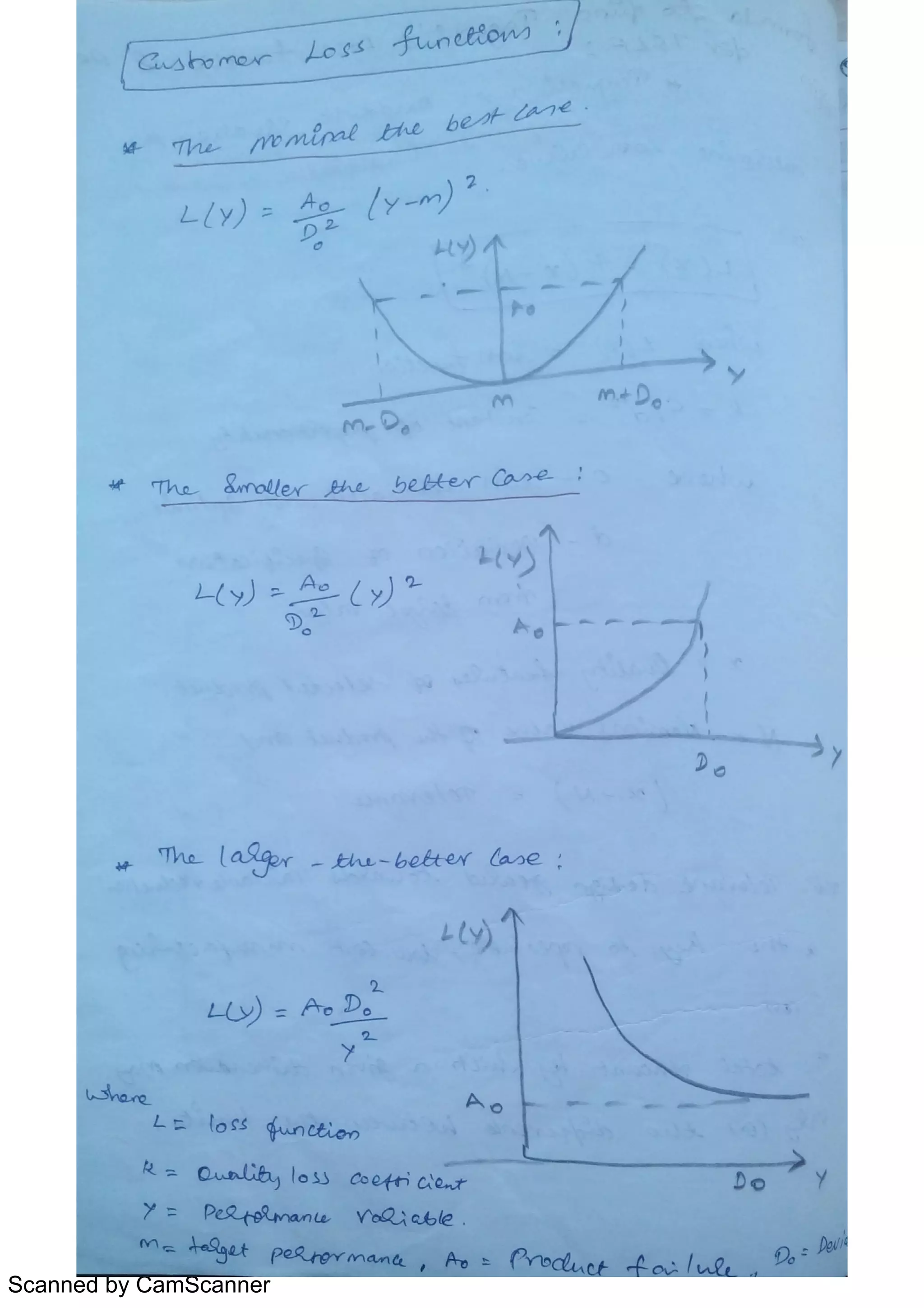

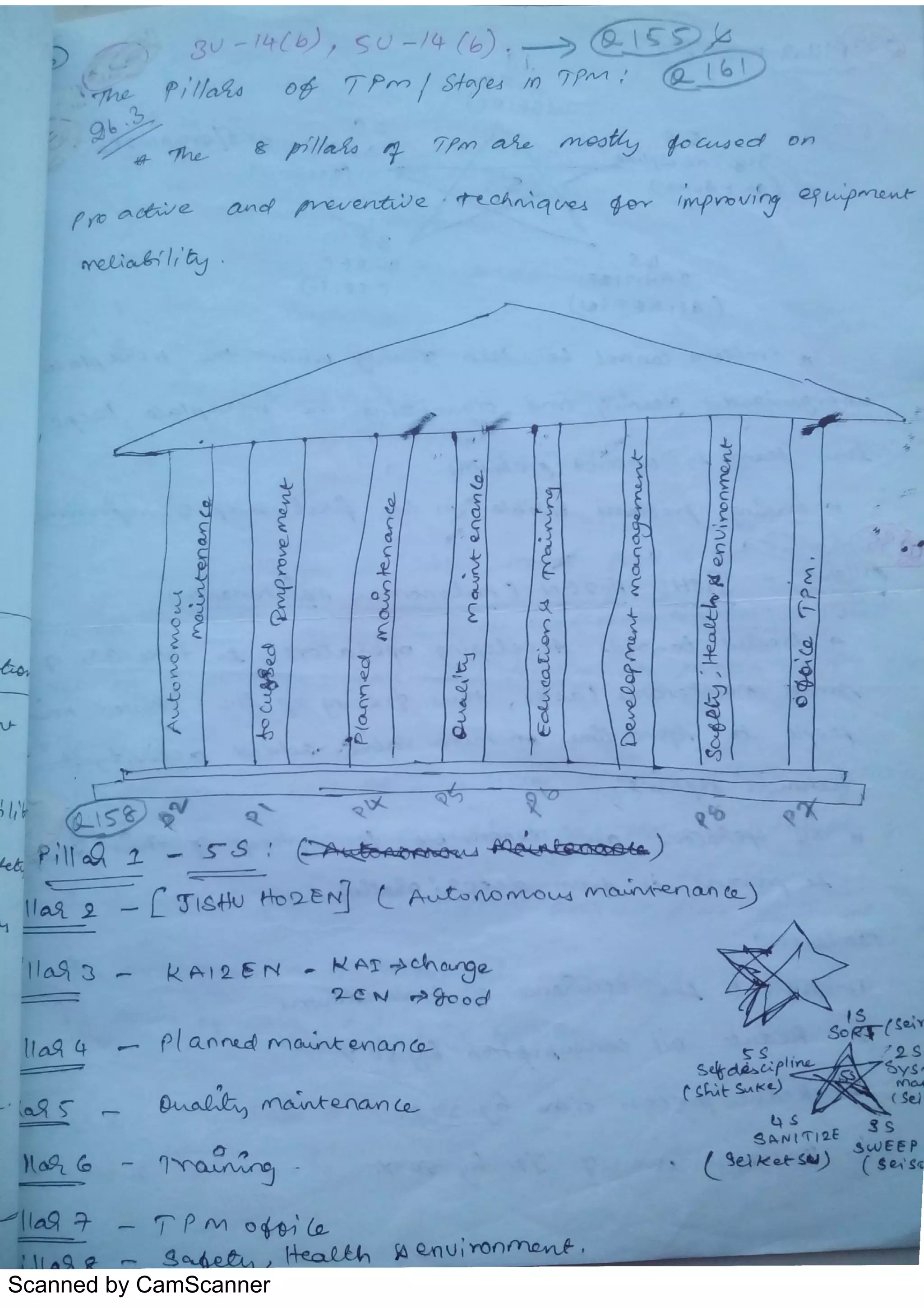

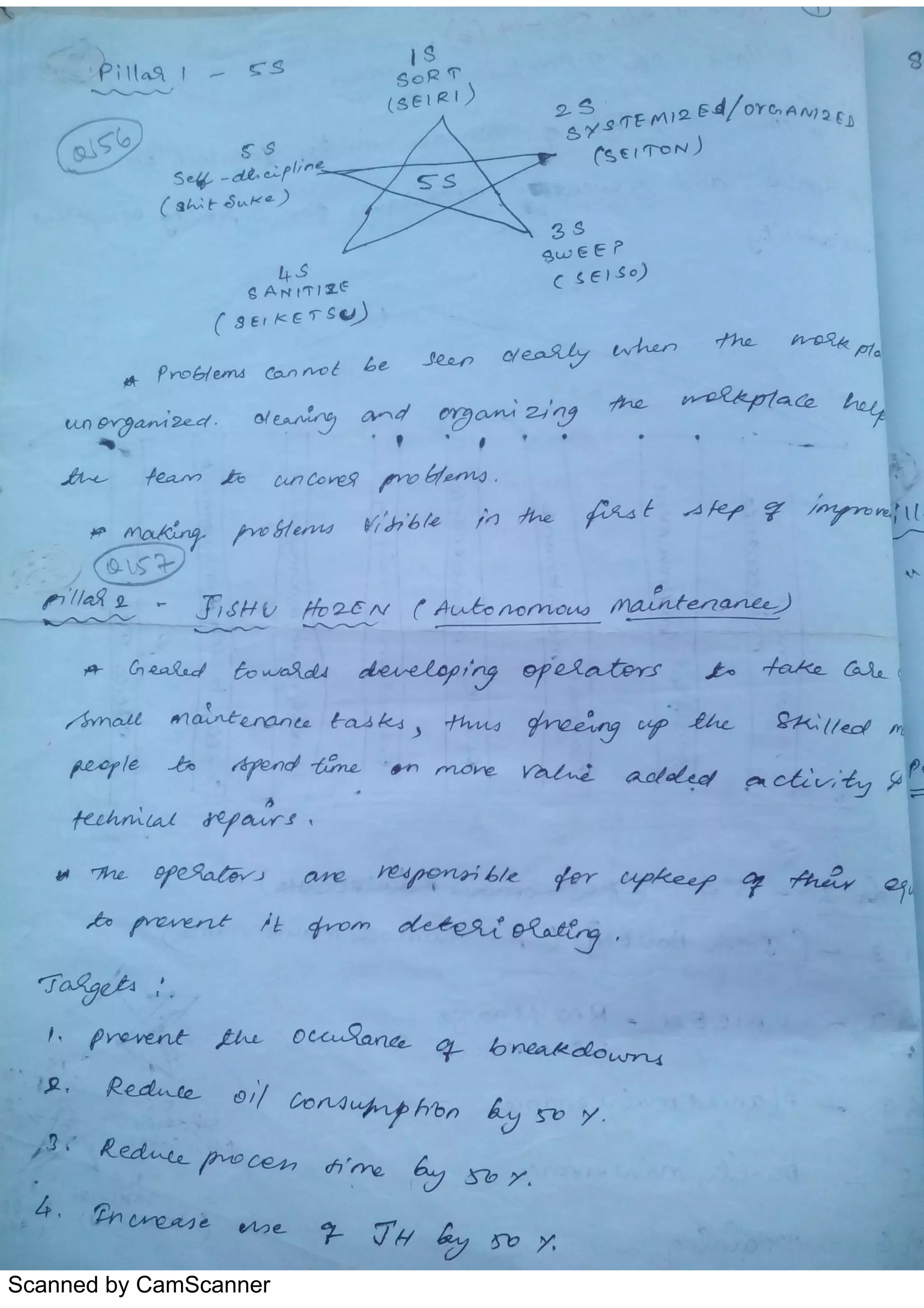

The document is a lesson plan for a course on Total Quality Management. It outlines 32 topics covered across 8 units. For each topic it lists the chapter number from the textbook, sources of information like PowerPoint presentations or videos, examples of real world applications, and the page numbers of relevant material. Some key topics included are control charts, process capability, Six Sigma methodology, Quality Function Deployment, Taguchi's quality loss function, and Total Productive Maintenance including its eight pillars. The lesson plan provides a structured guide for both the instructor and students on the scope and content of the course.