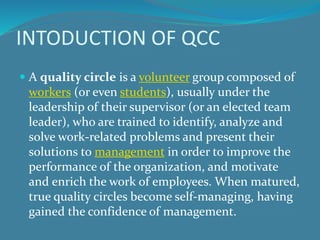

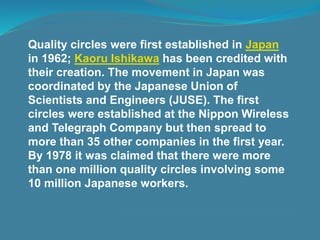

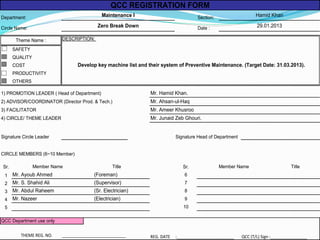

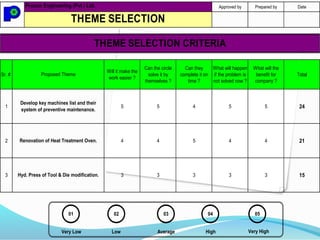

The document discusses quality circles (QCC), which are voluntary groups of workers that work to identify and solve work-related problems in order to improve organizational performance. Quality circles were first established in Japan in 1962 and involved workers volunteering to improve processes. The document then provides an example of a quality circle registration form and theme selection criteria used by Procon Engineering to establish a quality circle focused on preventative maintenance of key machines.

![0 0 0 0

0

0.5

1

Hours

Jan-

13

Feb-

13

Mar-

13

Apr-

13

SERIES21 0 0 0 0

COOLING TOWER #

173605 [HEAVY PRESS

SHOP (GENERAL)]](https://image.slidesharecdn.com/6d001e66-9cad-4a0e-8aad-789103e14024-160222060658/85/QCC-Presentation-29-320.jpg)

![0 0 0 0

0

0.5

1

Hours

Jan-

13

Feb-

13

Mar-

13

Apr-

13

SERIES22 0 0 0 0

HOIST (LIFT) # 178205

[COIL CUTTING

AREA (GENERAL)]](https://image.slidesharecdn.com/6d001e66-9cad-4a0e-8aad-789103e14024-160222060658/85/QCC-Presentation-30-320.jpg)