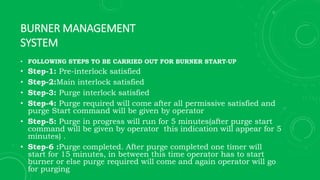

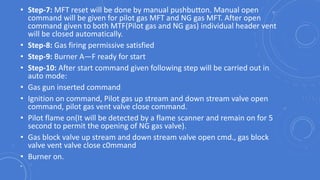

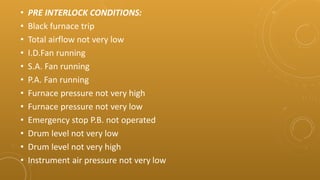

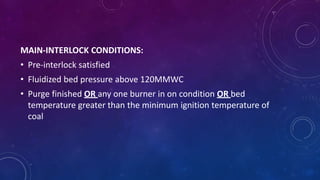

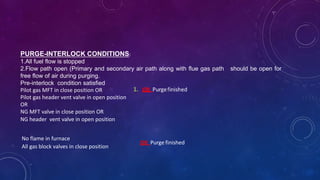

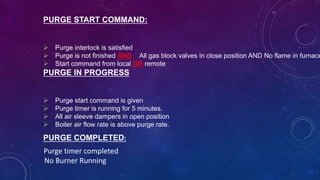

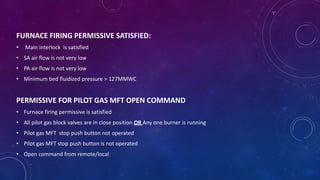

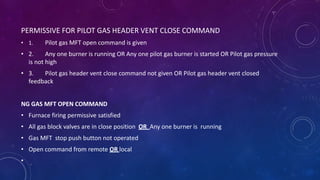

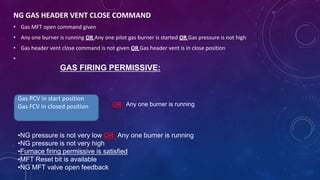

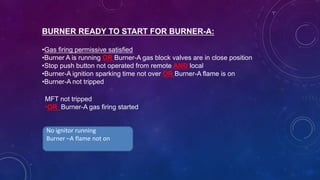

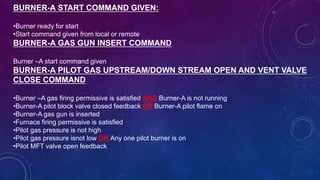

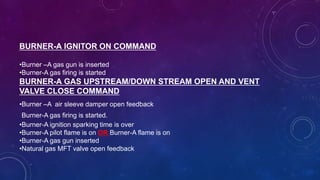

The document outlines the startup sequence for a CFBC burner. It involves 14 steps: 1) satisfying pre-interlocks, 2) satisfying main interlocks, 3) satisfying purge interlocks, 4) starting purge for 5 minutes, 5) purge completing, 6) resetting MFTs, 7) satisfying gas firing permissives, 8) burners becoming ready for start, 9) starting burner A through 10 automatic commands, and 10) burner A gas firing starting. It provides details on the conditions that must be met at each step.