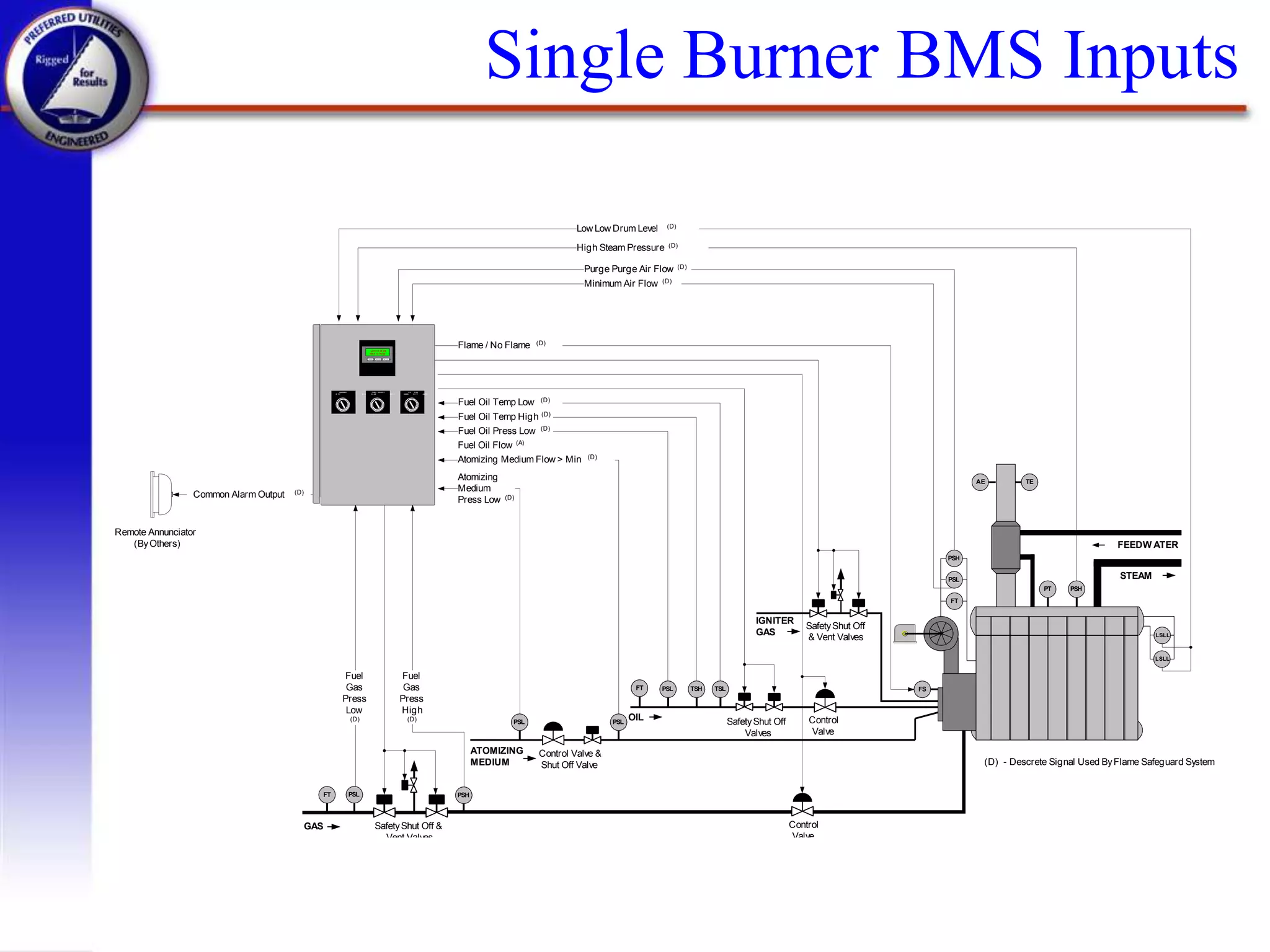

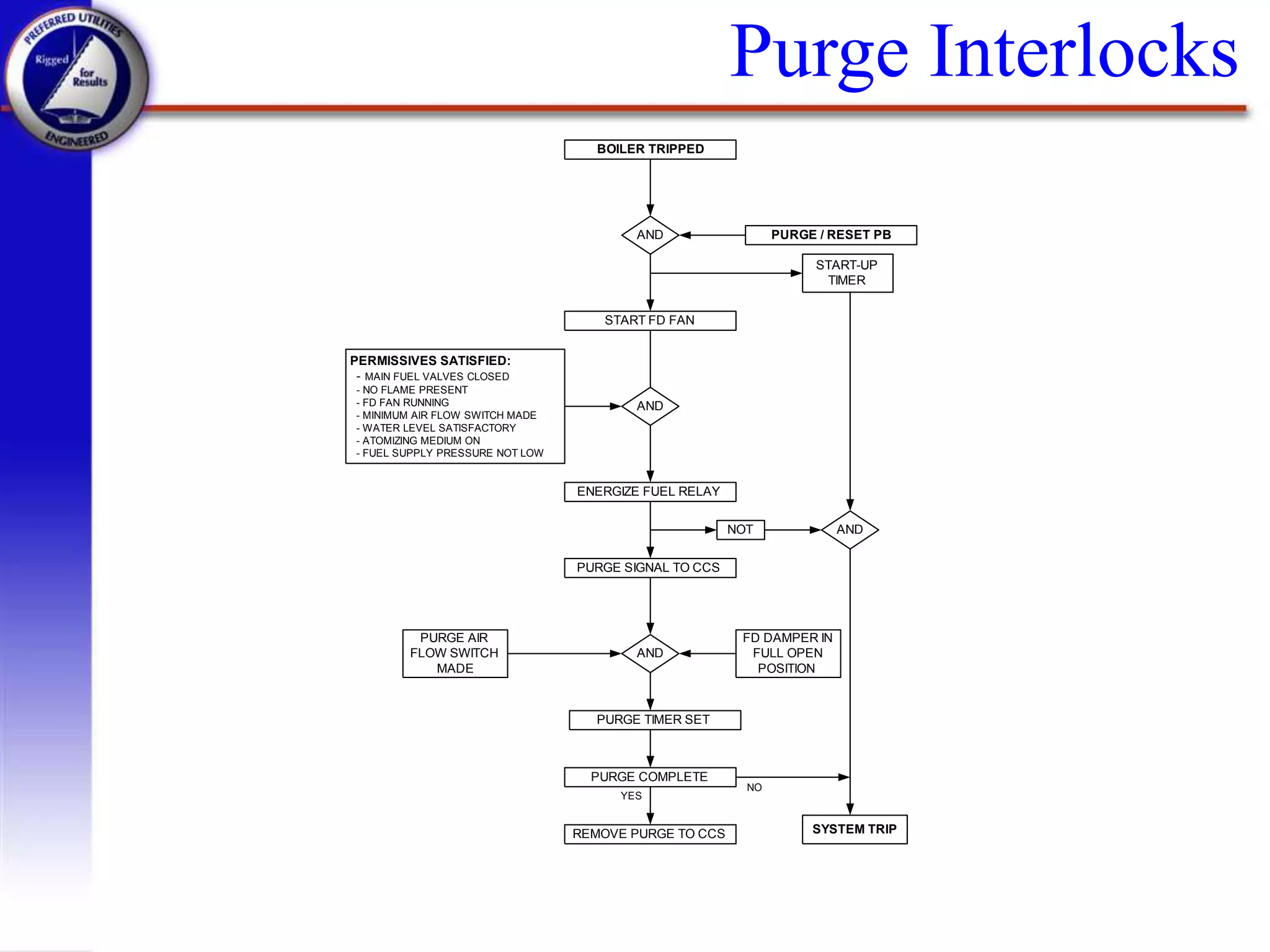

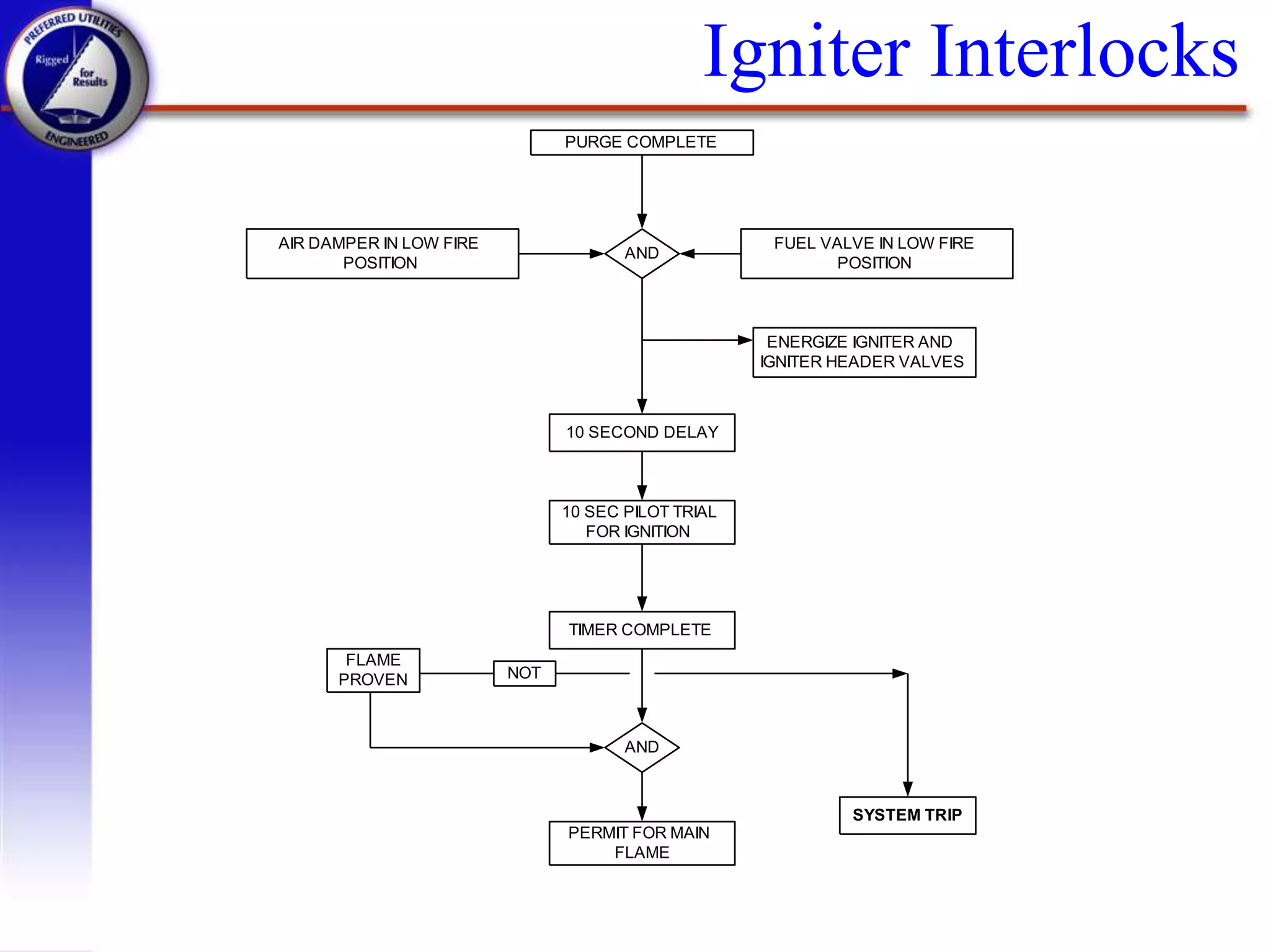

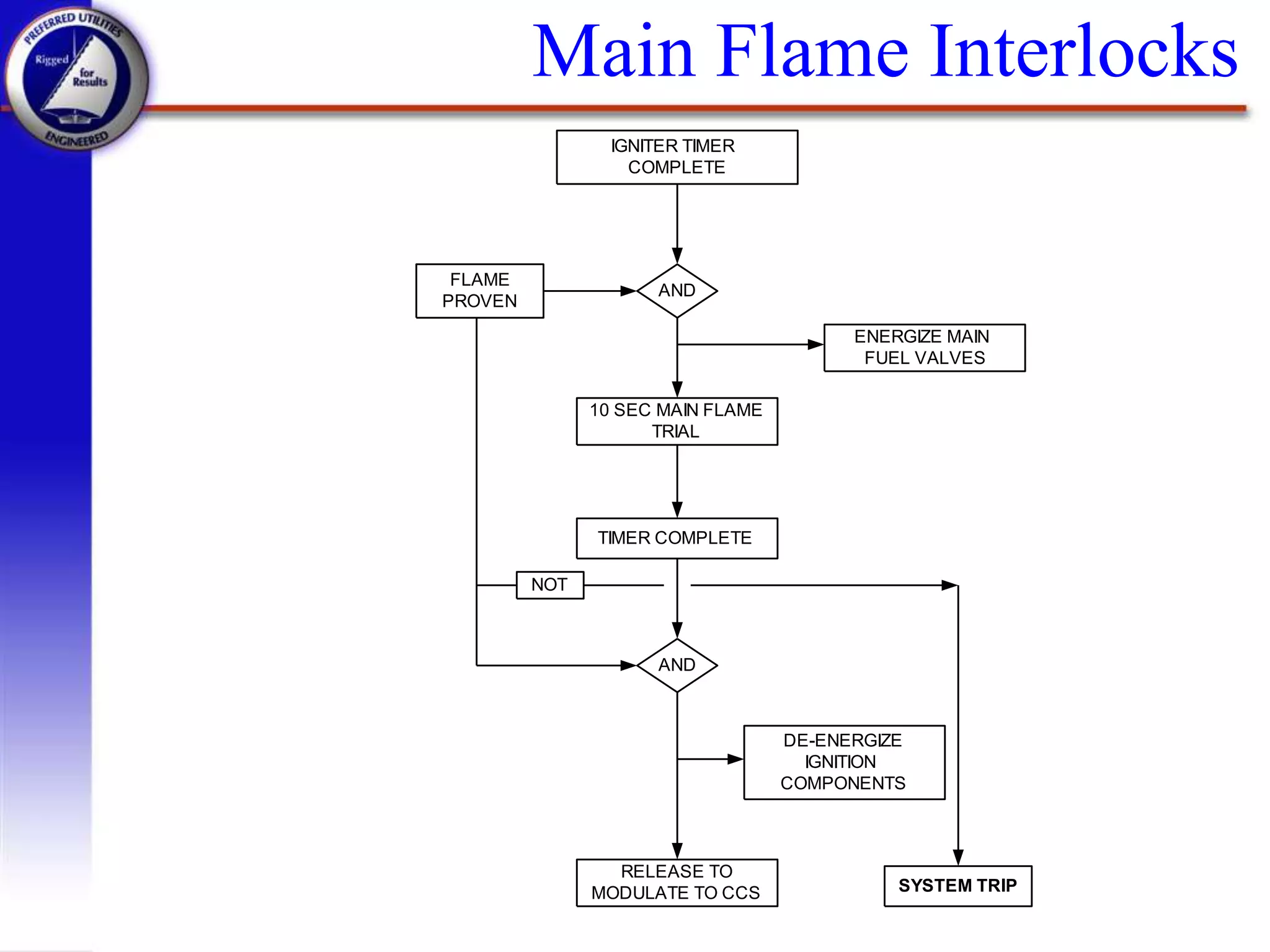

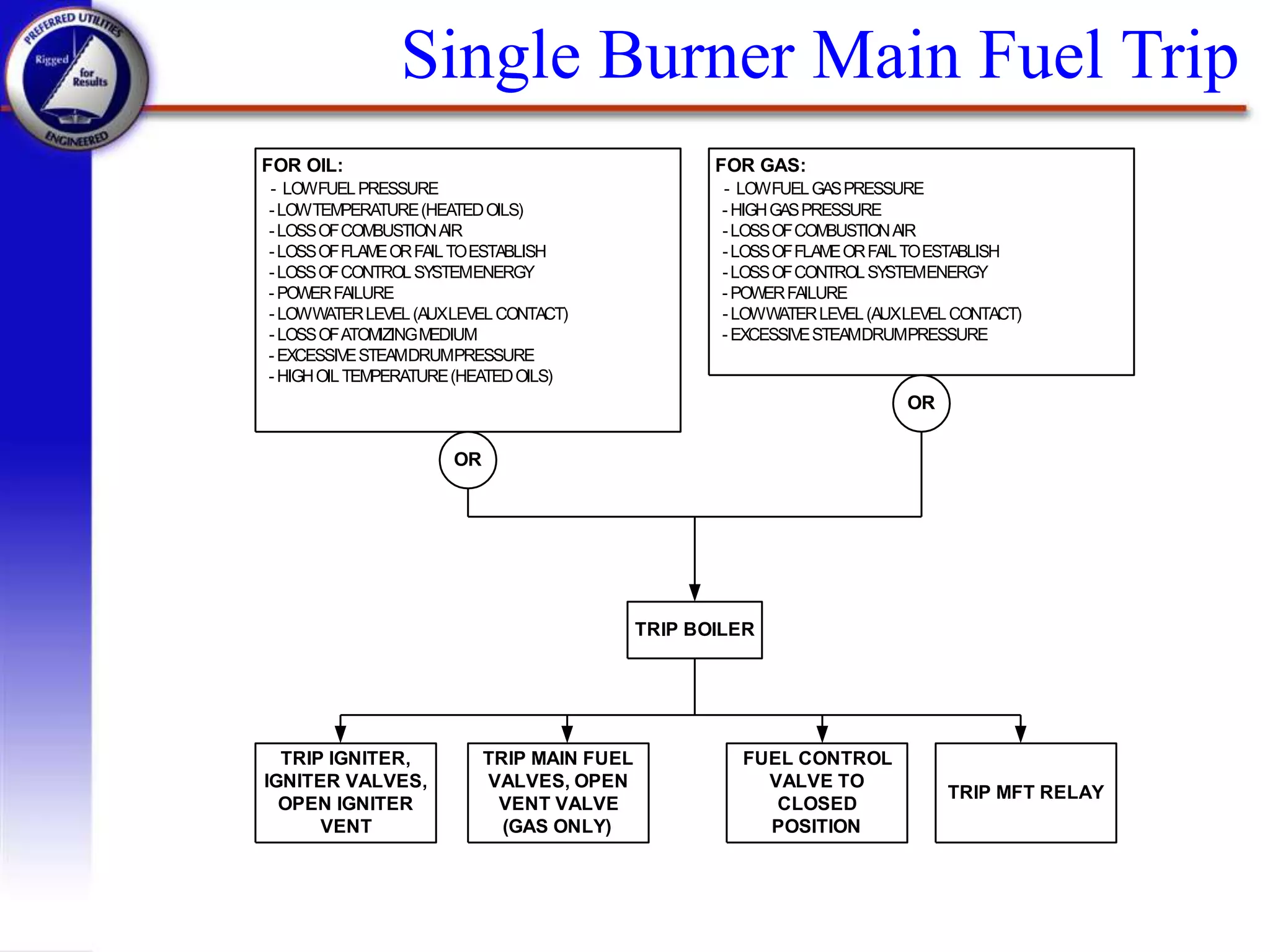

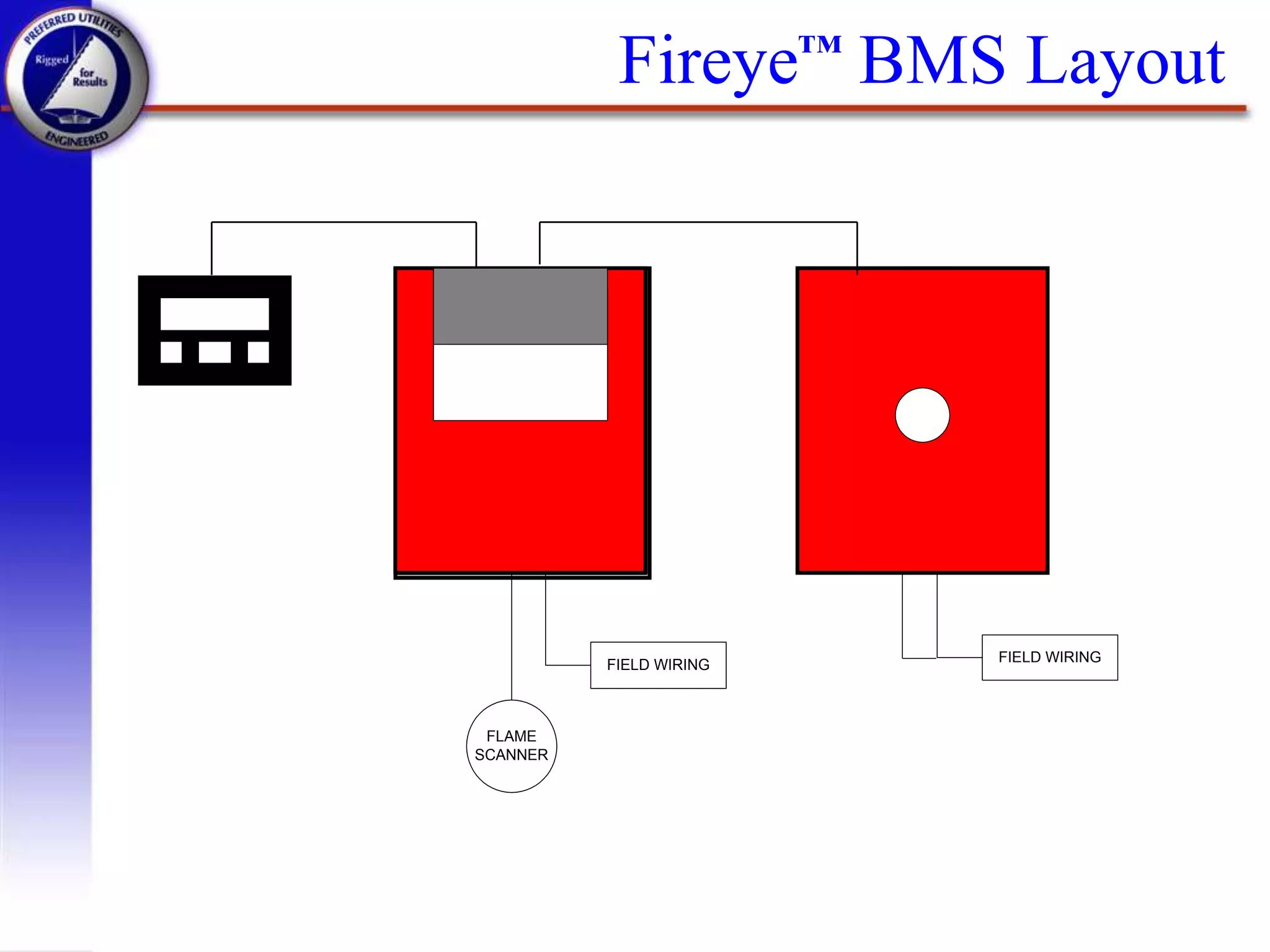

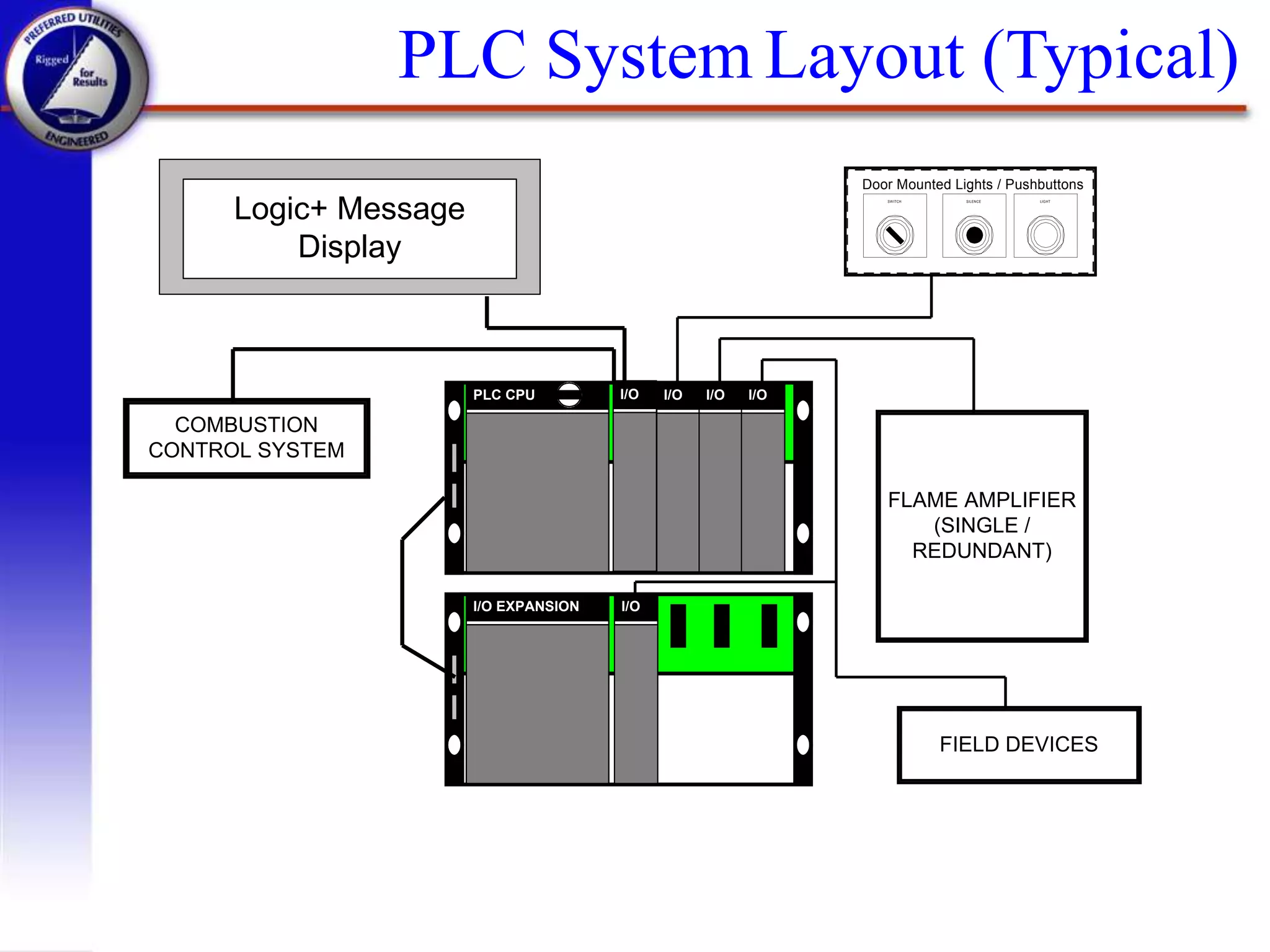

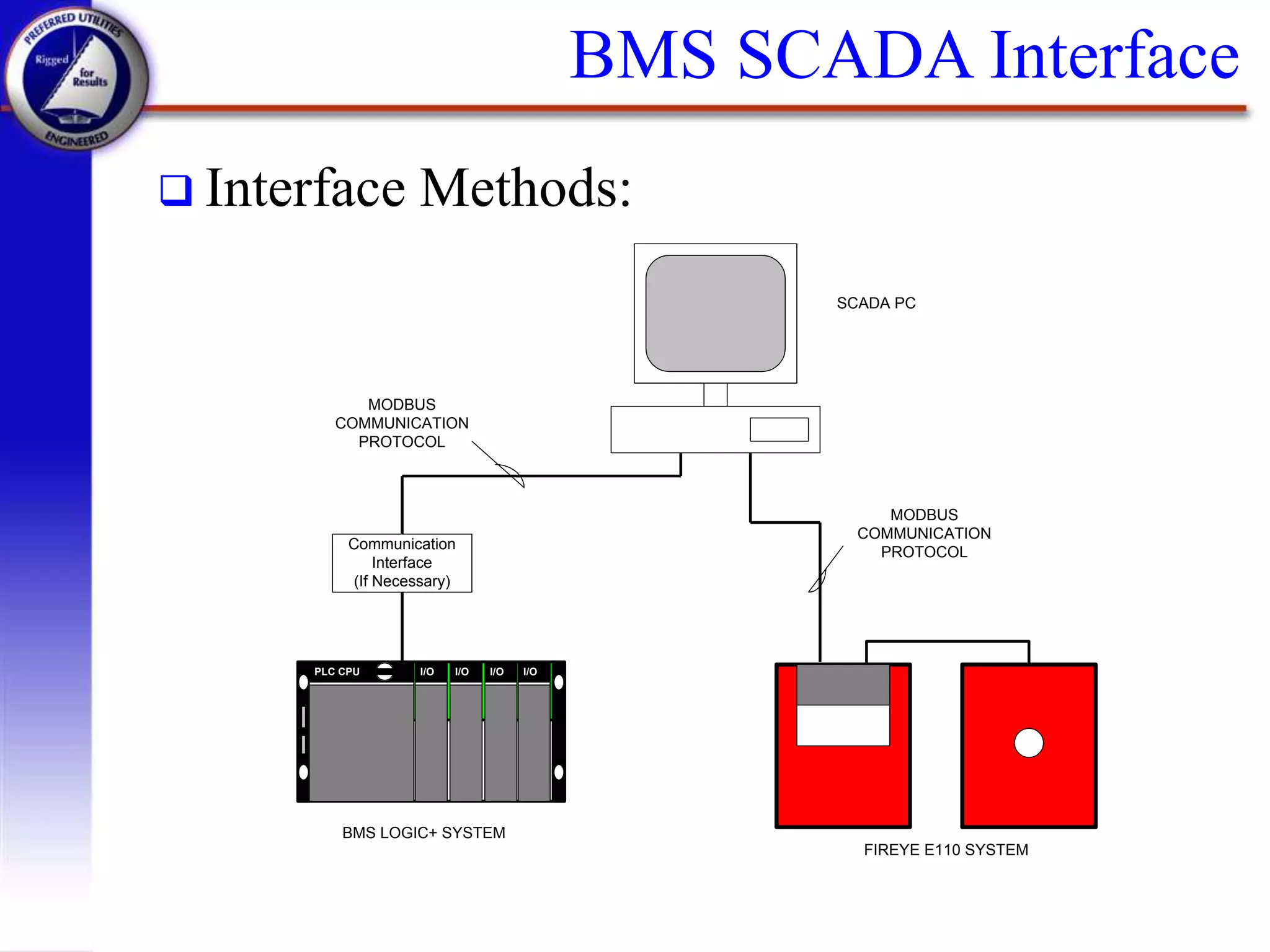

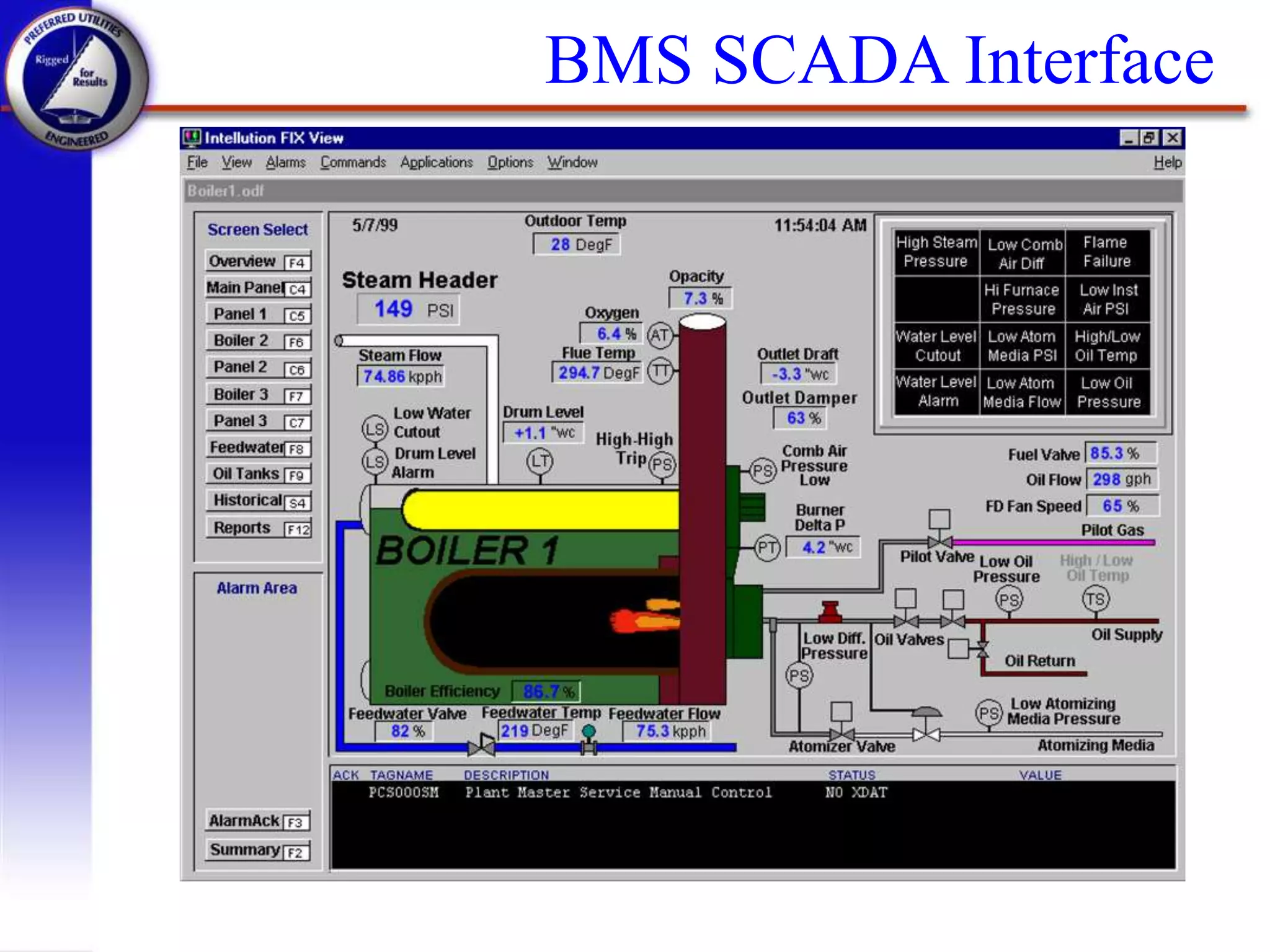

This document discusses burner management systems (BMS), including their objectives, design standards, logic, types, and interface with SCADA systems. A BMS is defined as a control system dedicated to boiler safety during startup, operation, and shutdown. The document outlines BMS logic including purge, igniter, and main flame interlocks. It describes early hardwired and solid state systems, as well as modern microprocessor-based and PLC-based BMS. PLC systems offer flexibility, redundancy, and integration with SCADA. In summary, the document provides an overview of BMS design, functionality, and system types.