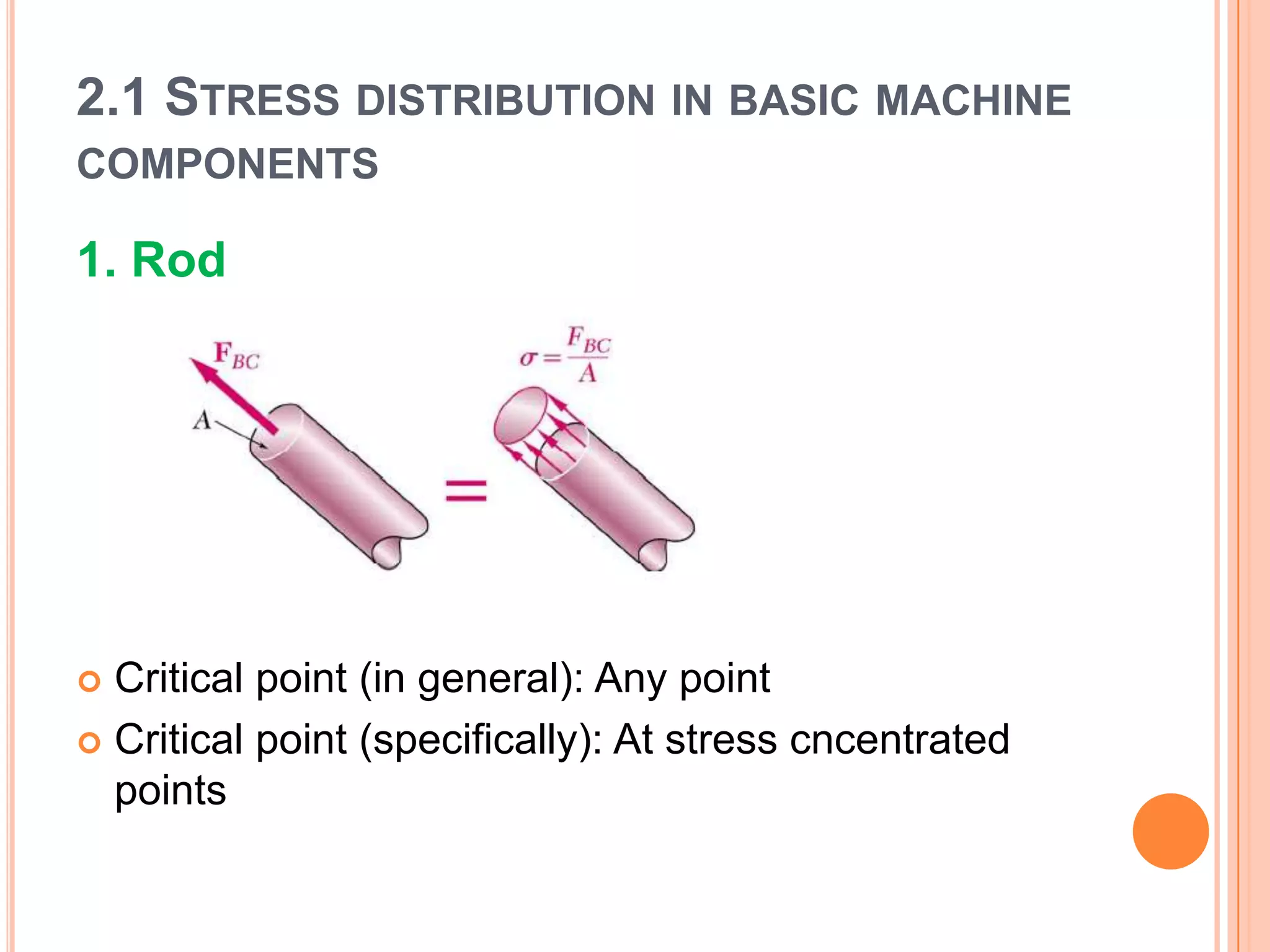

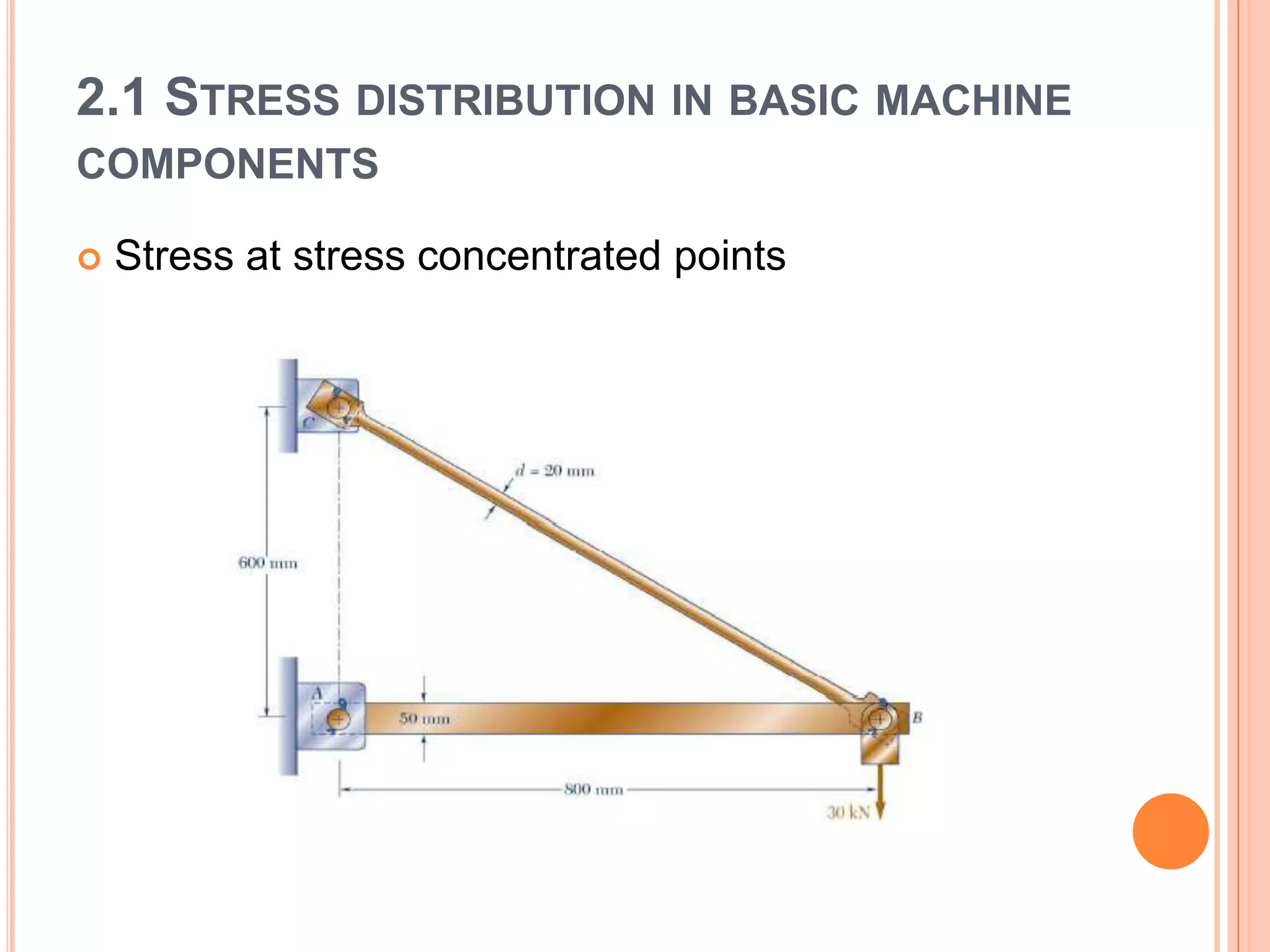

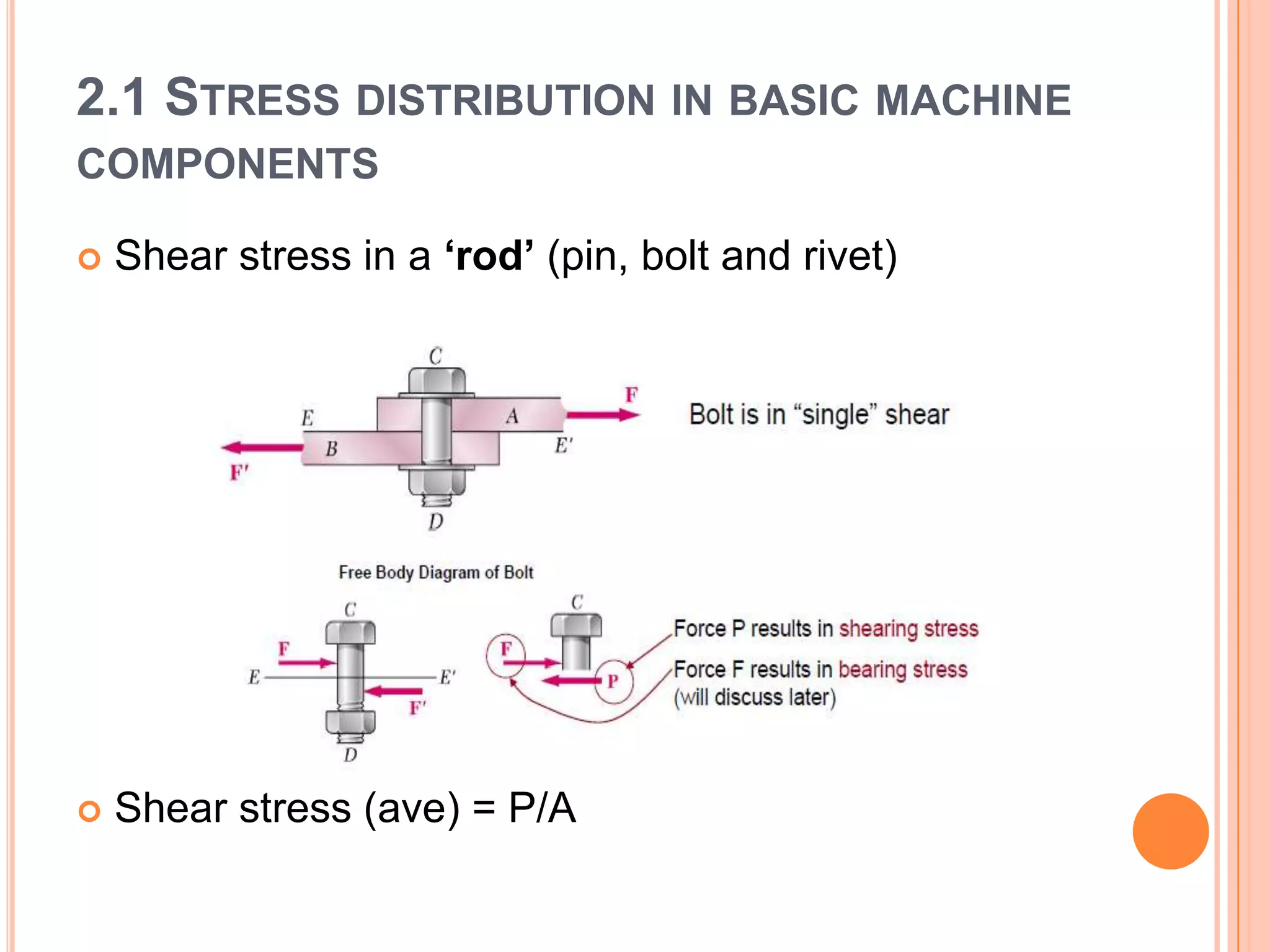

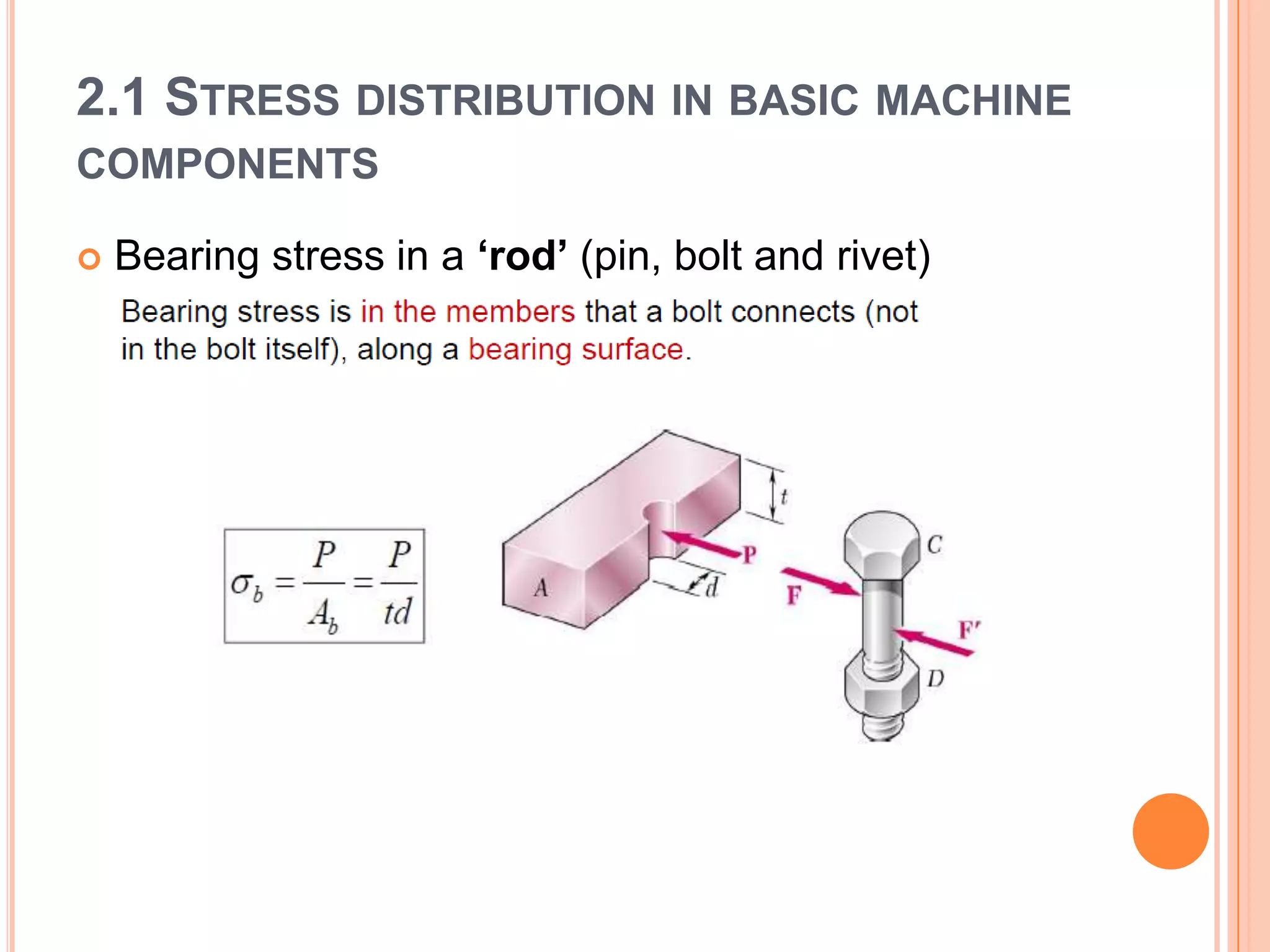

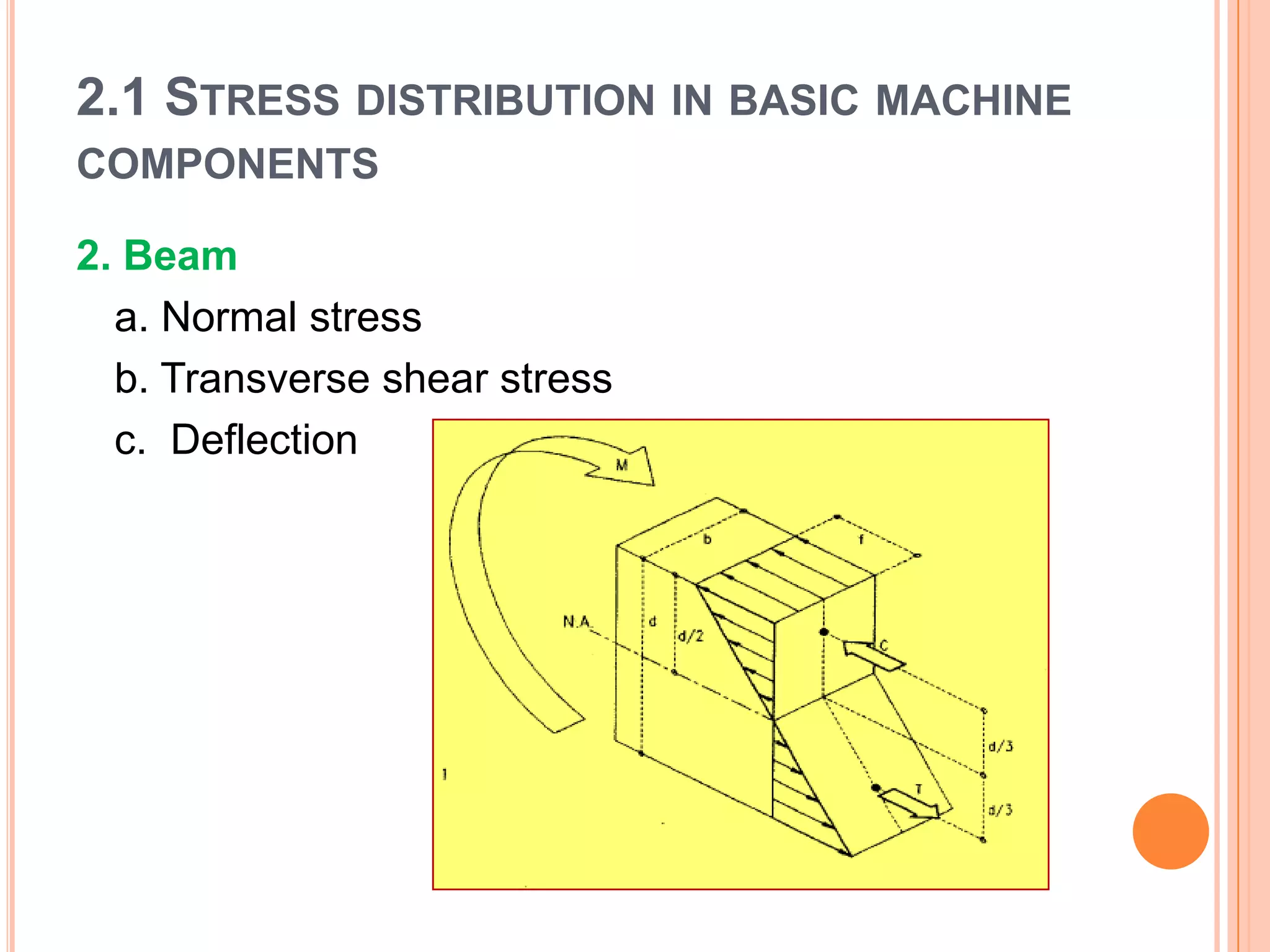

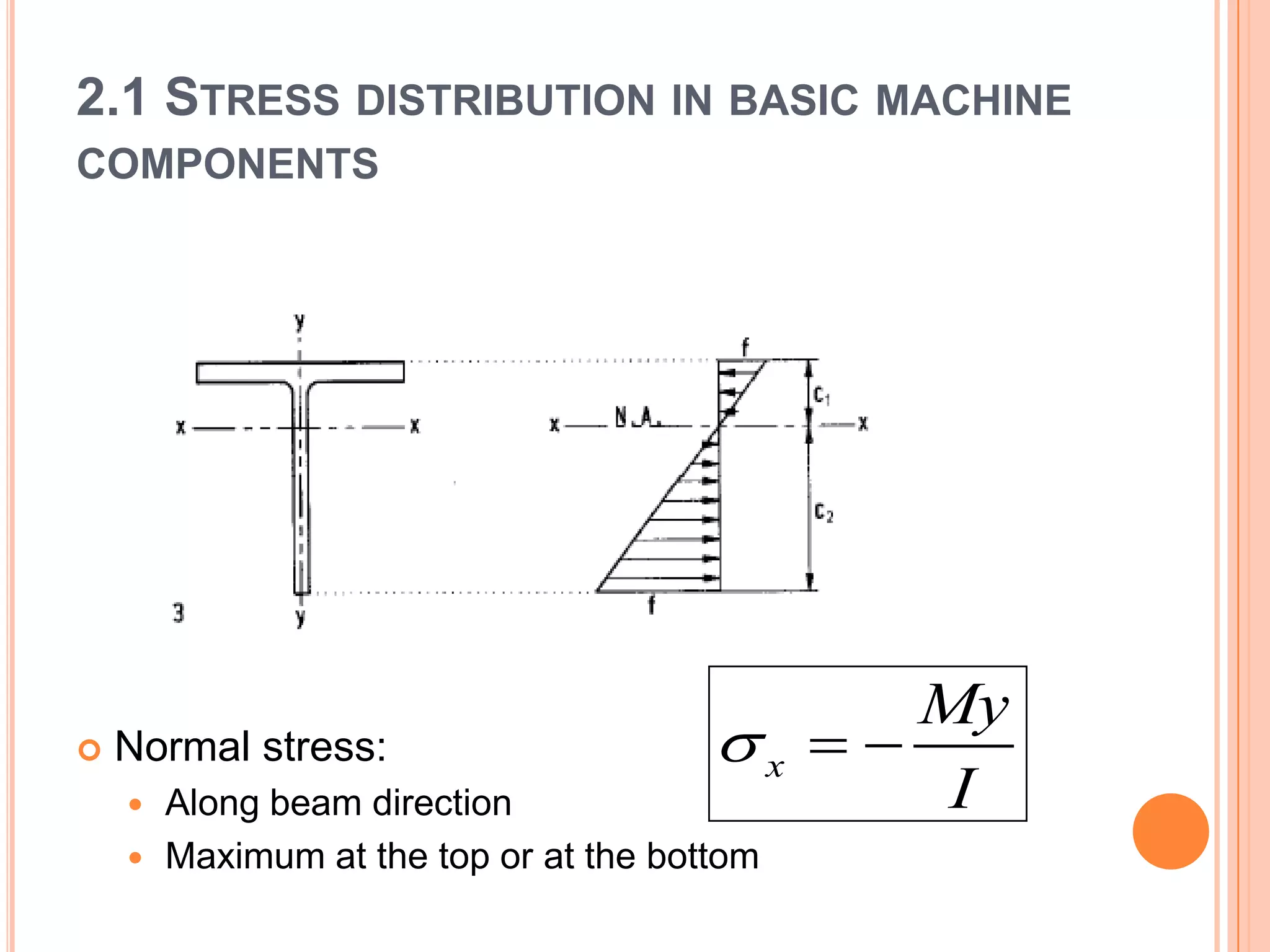

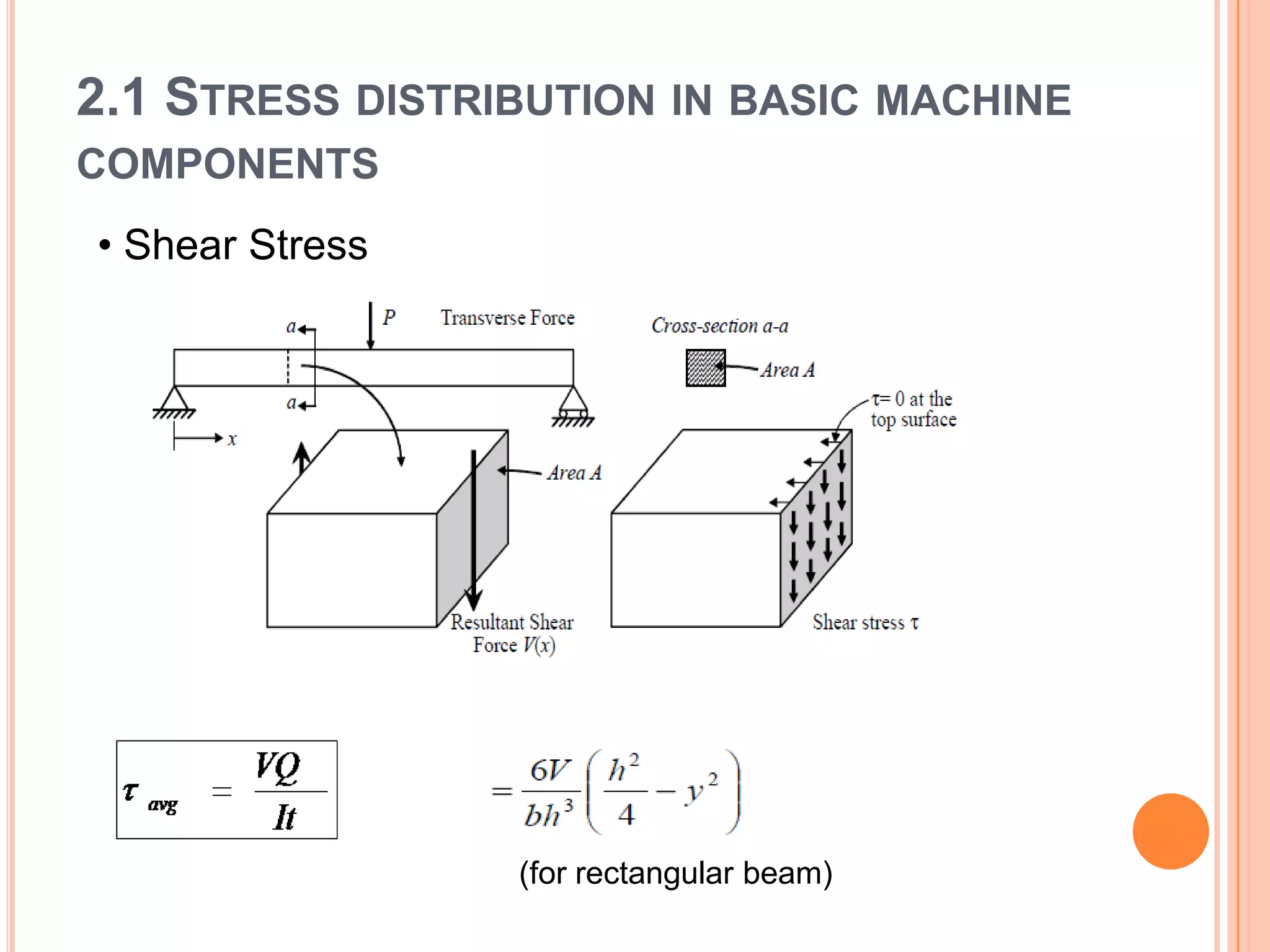

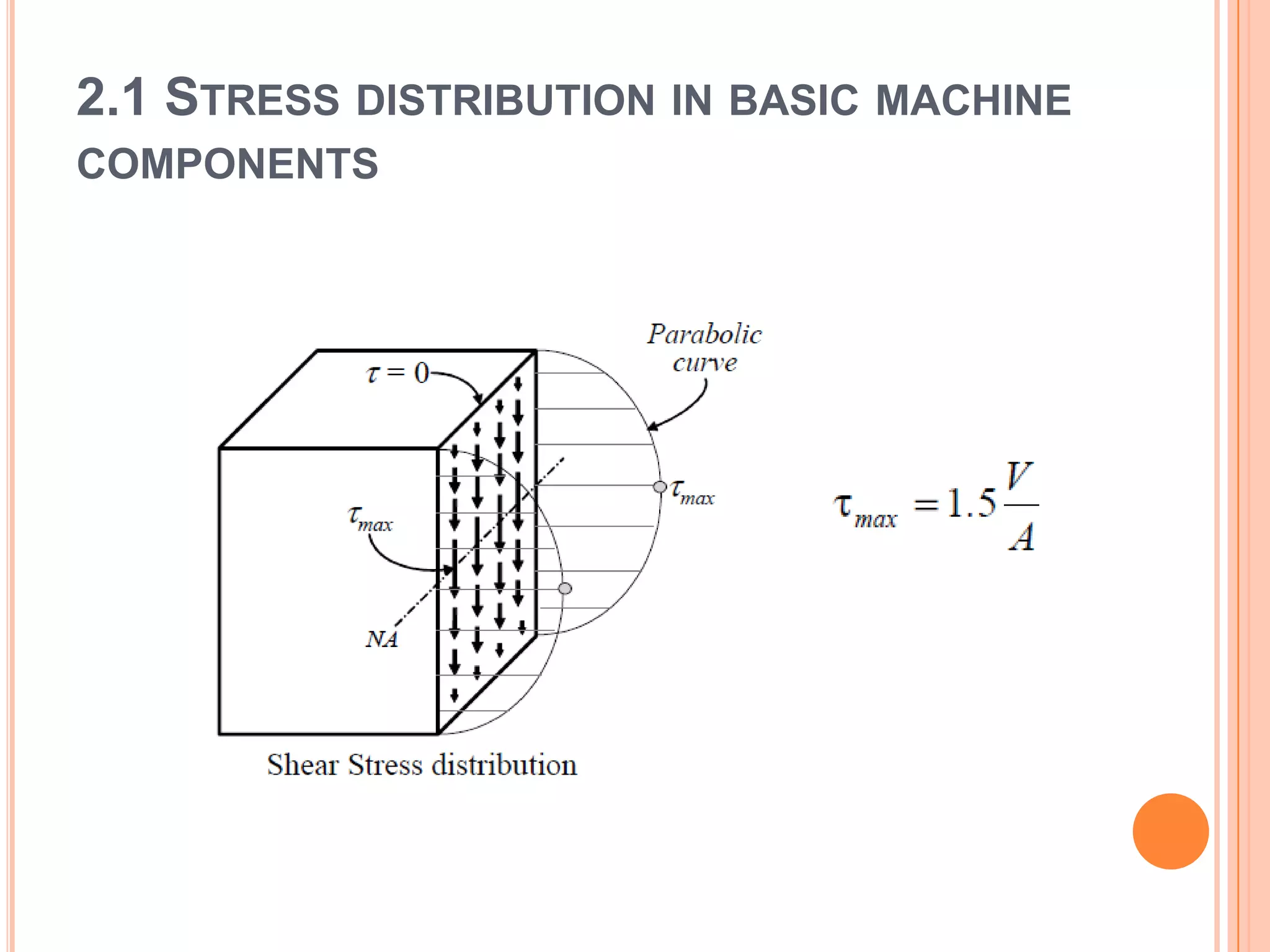

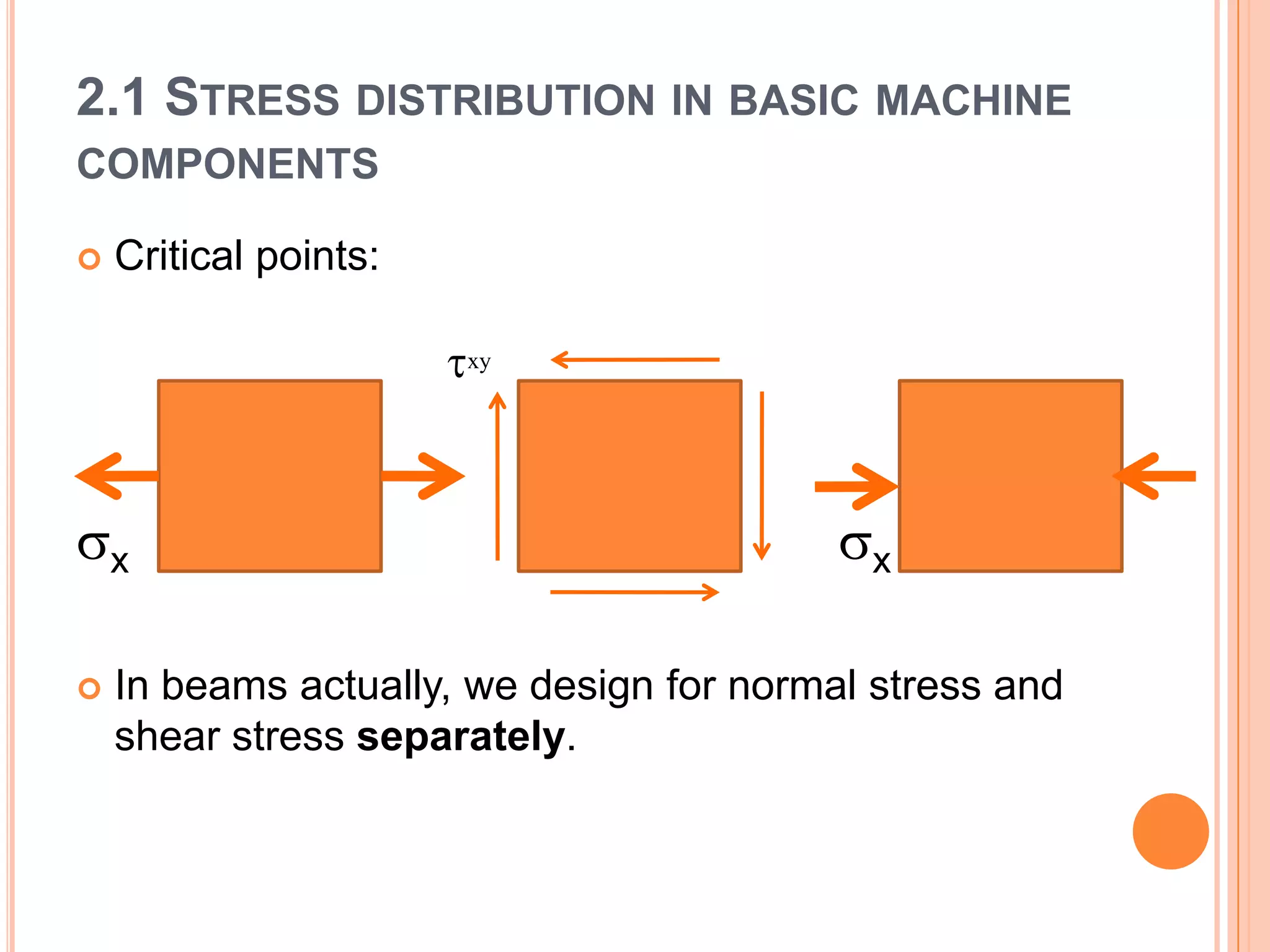

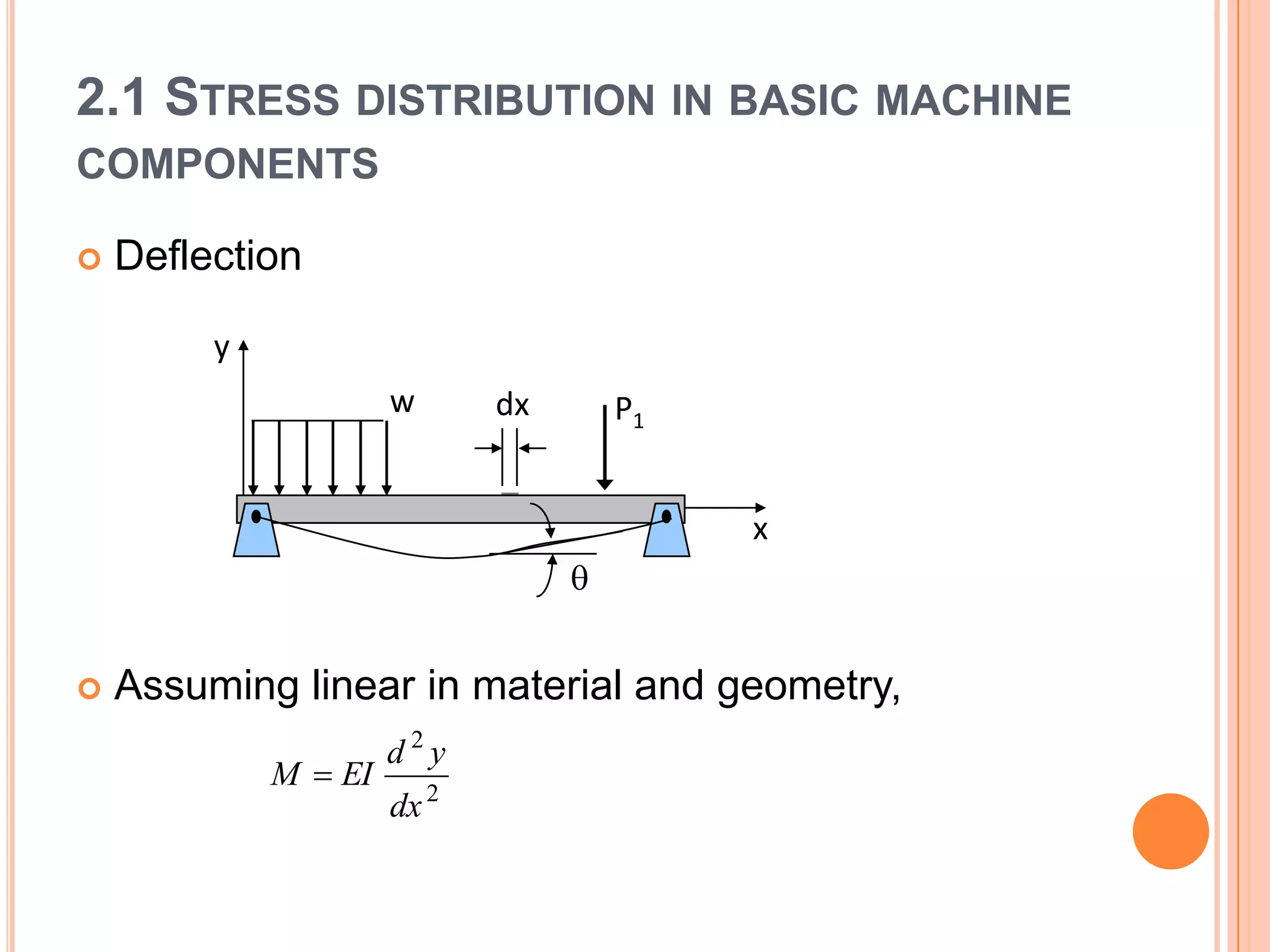

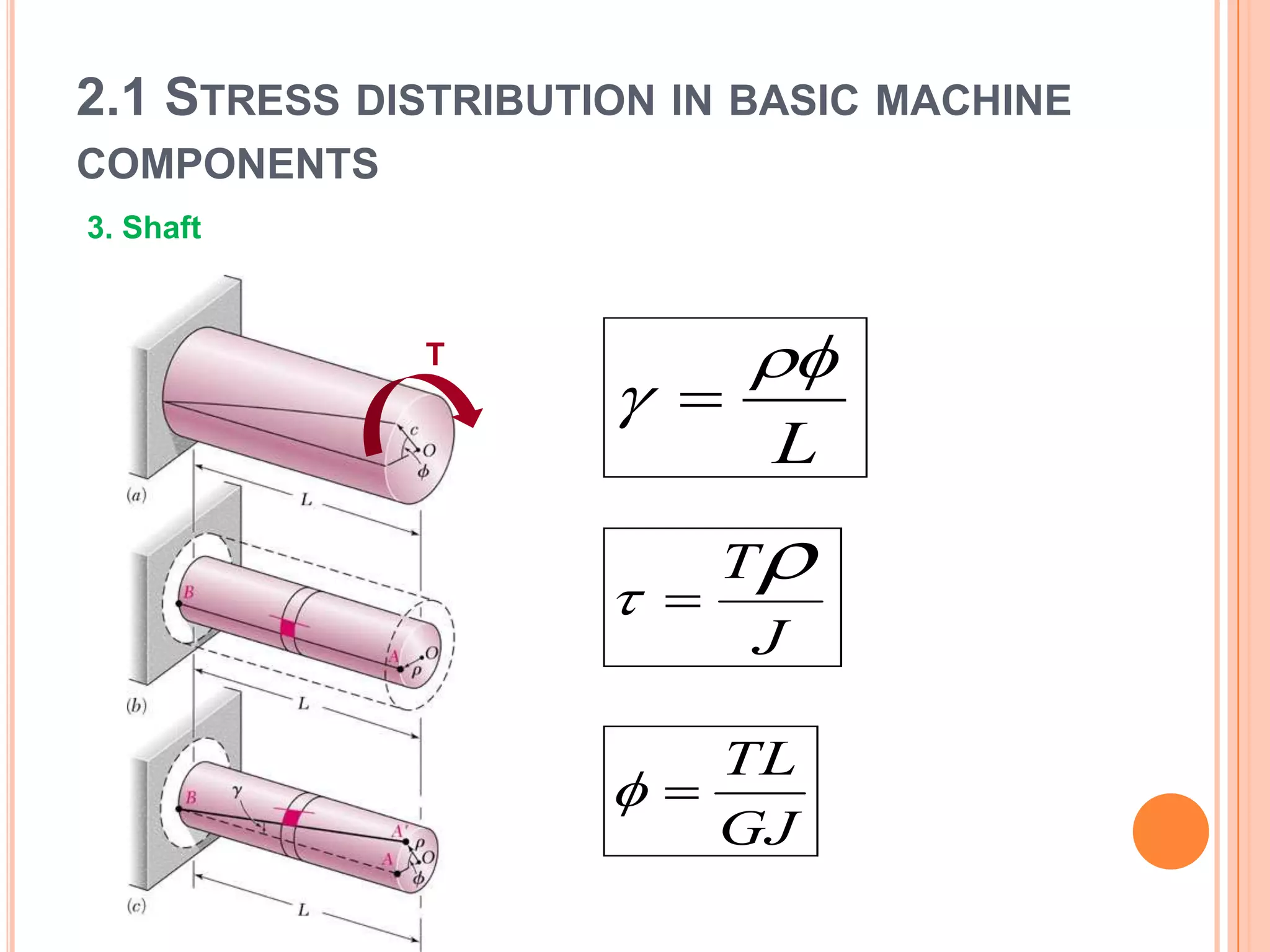

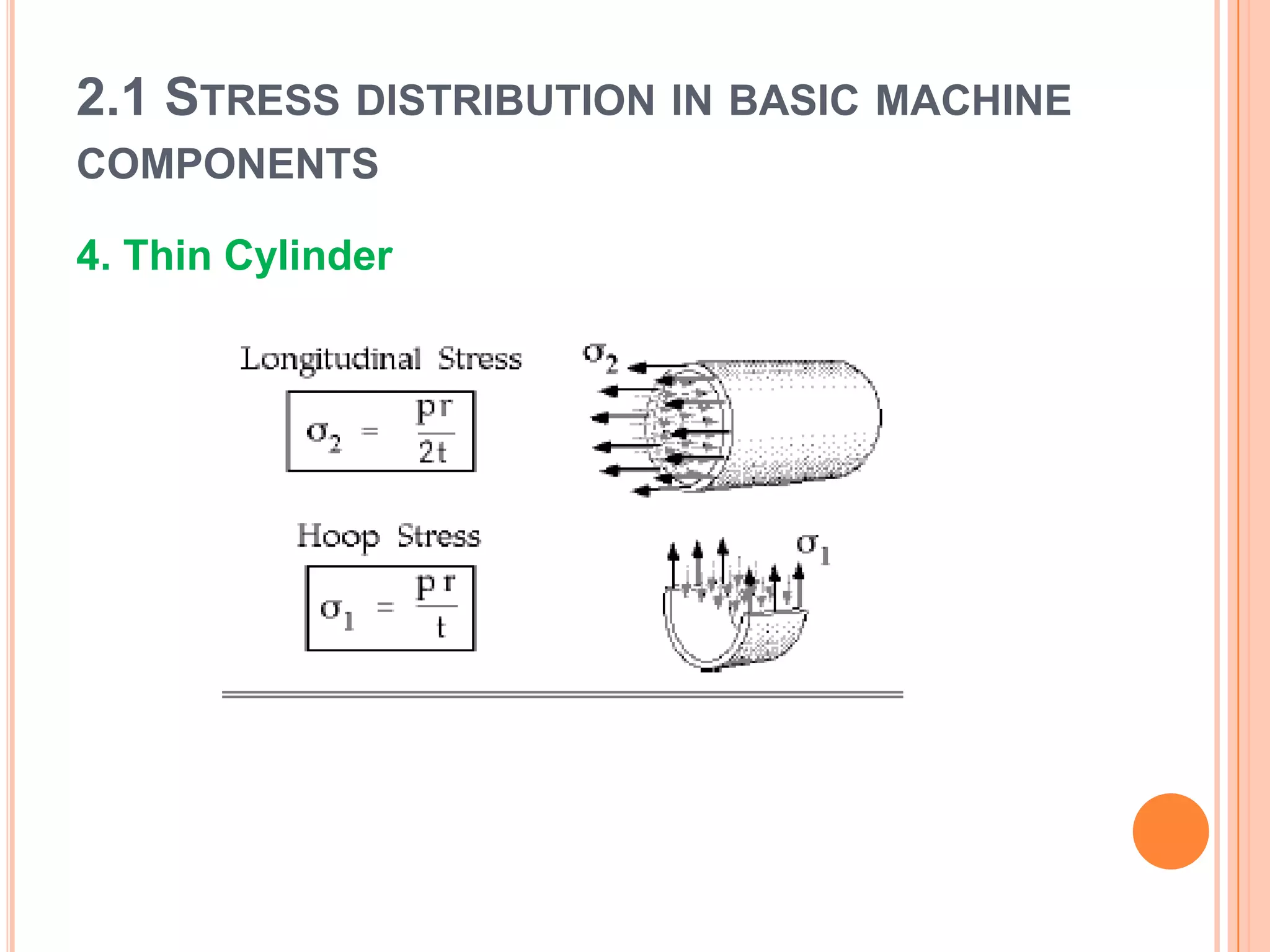

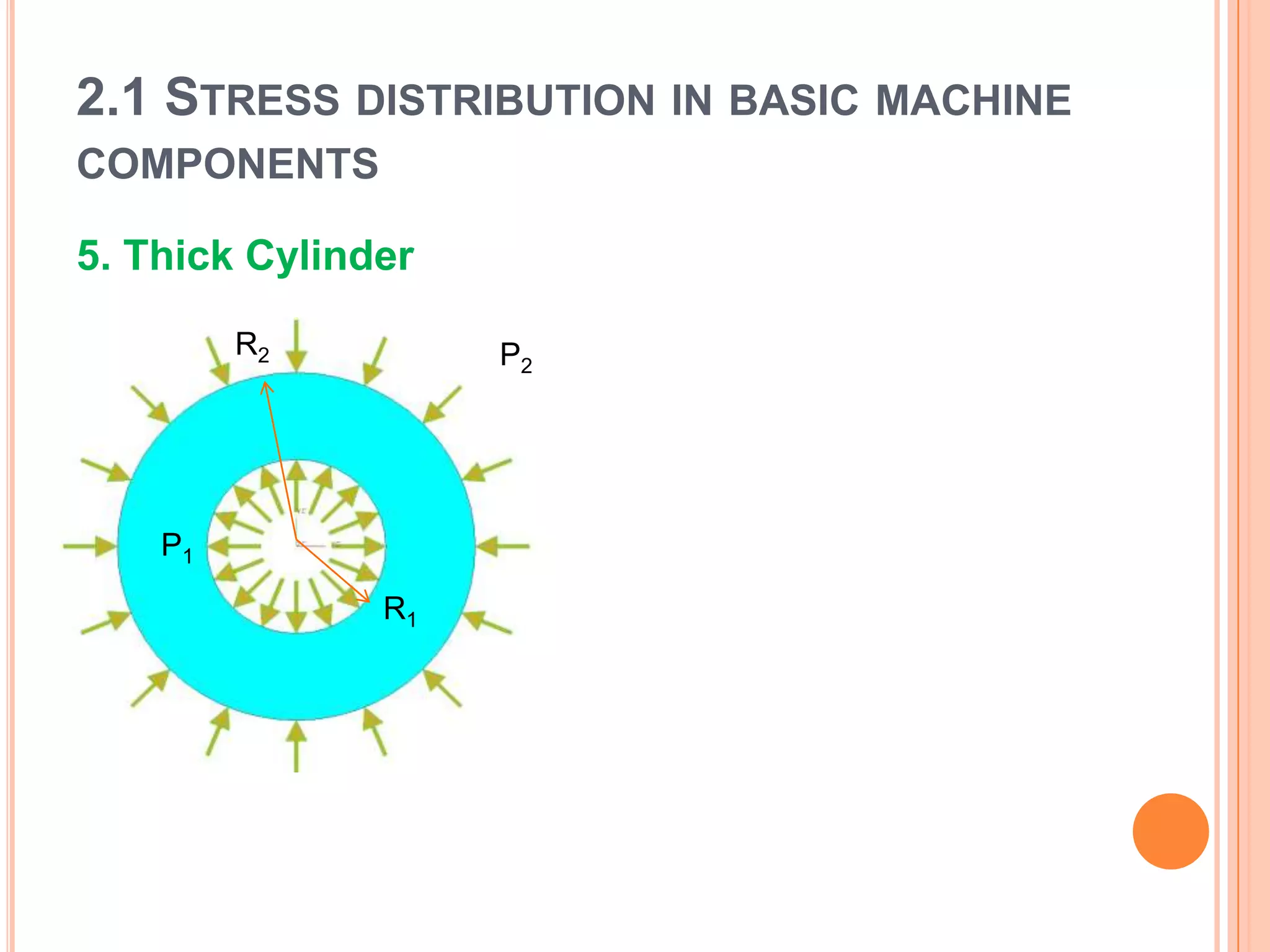

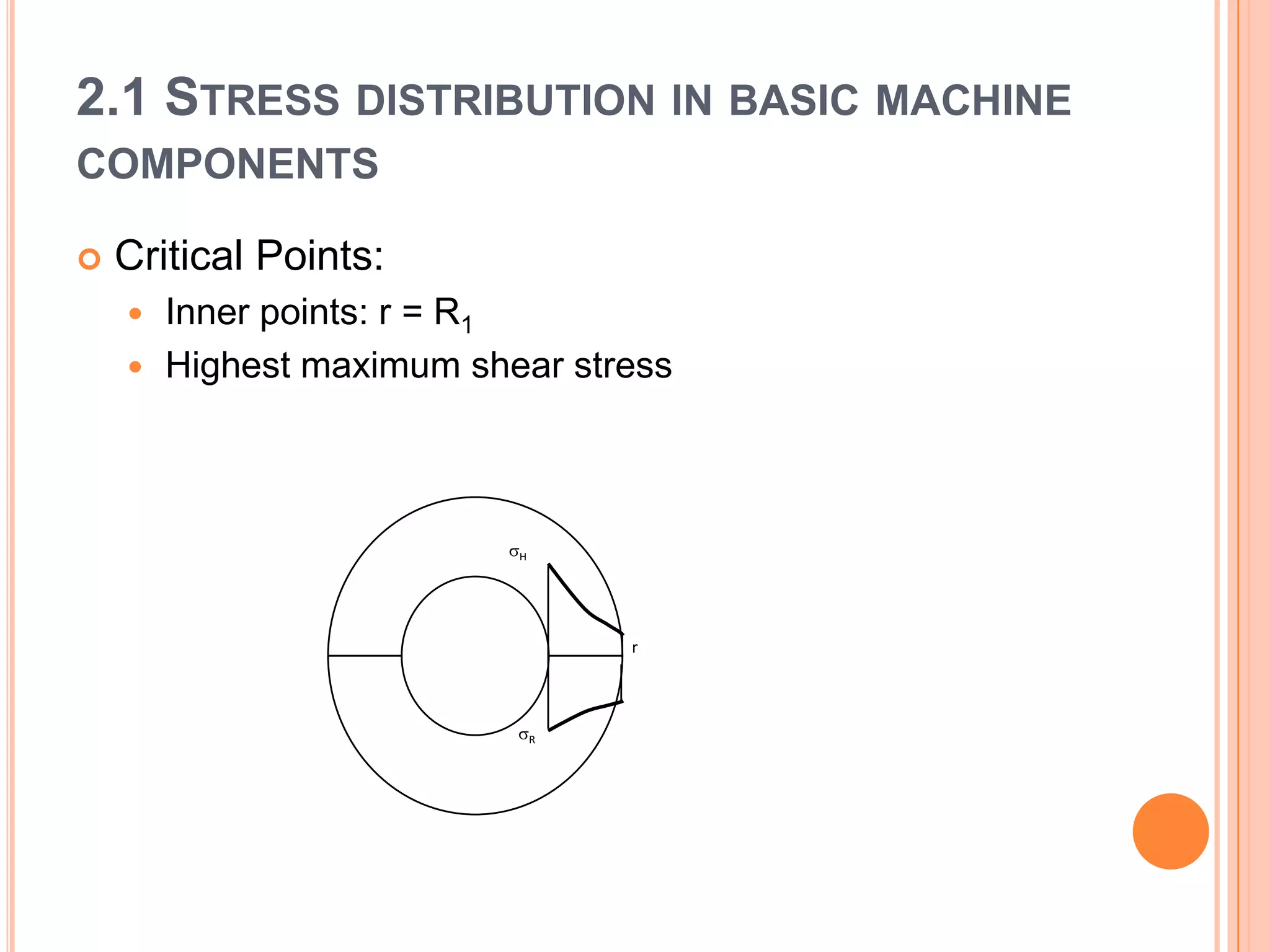

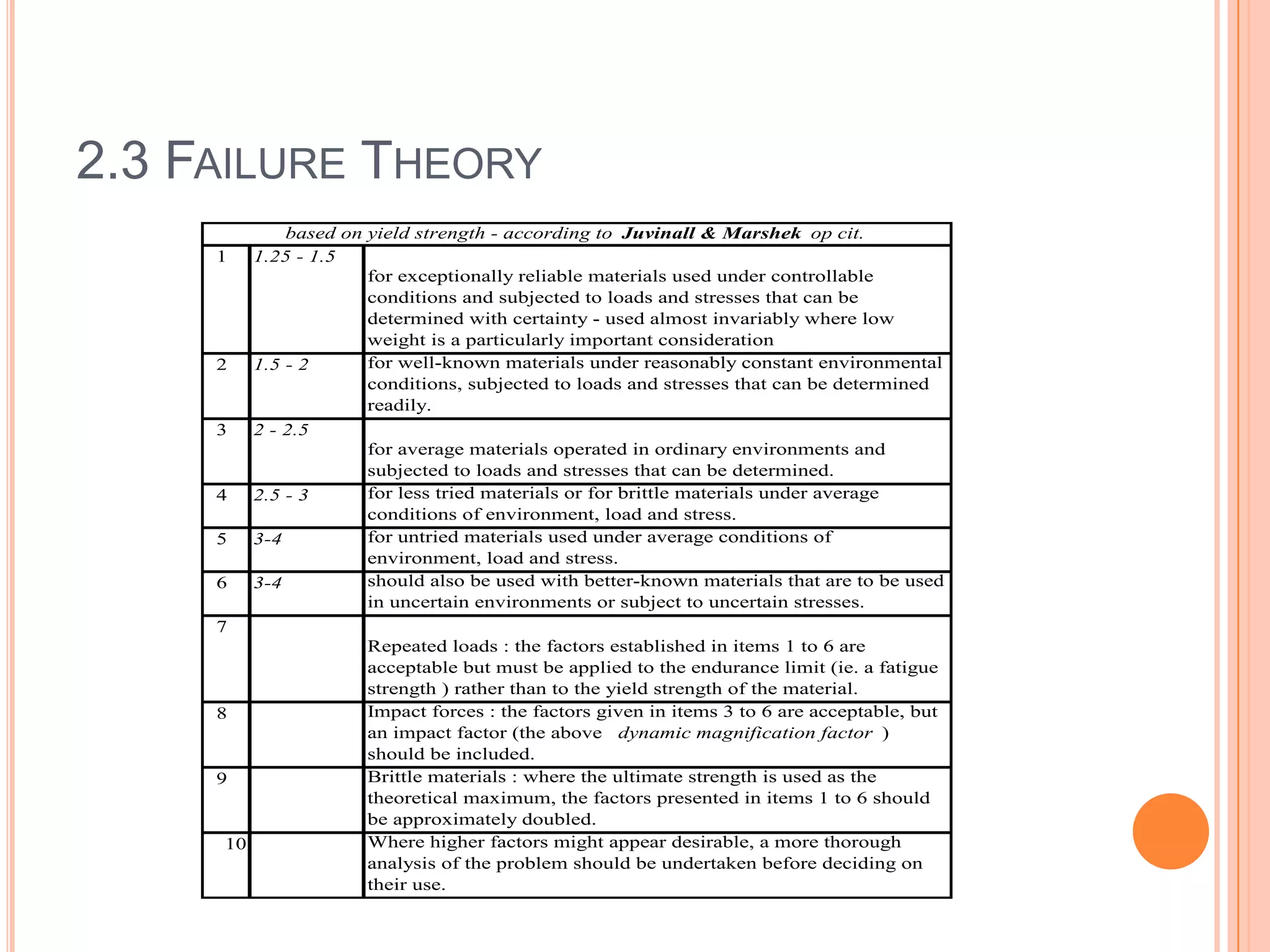

The document discusses stress distribution in basic machine components such as rods, beams, shafts, thin cylinders, and thick cylinders. It describes the different types of stresses that act on these components, including normal stress, shear stress, bearing stress, and deflection. The key points covered are the stress concentration at critical points, the formulas used to calculate stresses, and the factors considered in the design of these components for both stress and strength.