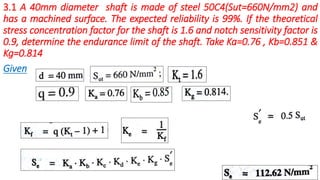

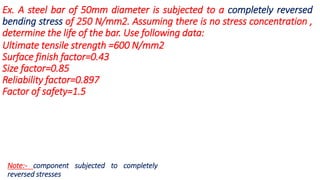

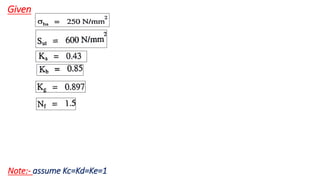

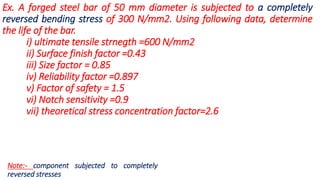

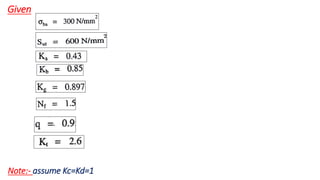

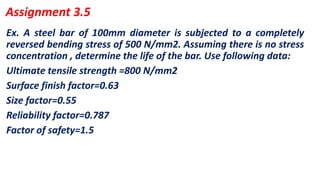

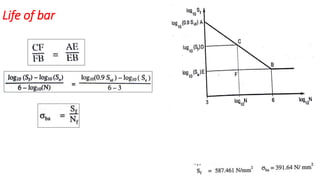

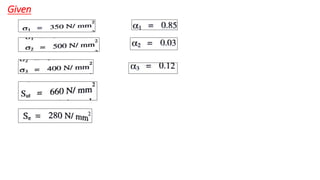

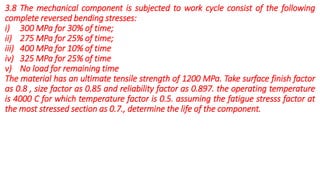

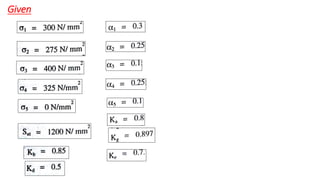

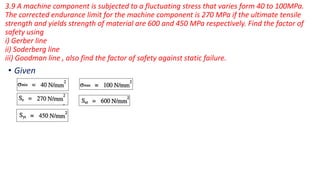

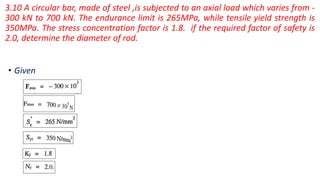

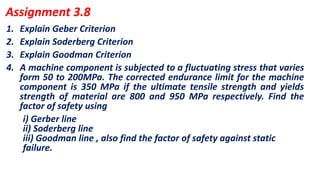

Given:

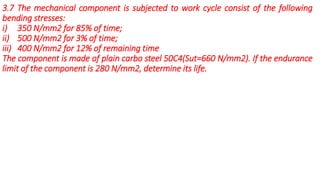

Stresses:

i) 350 N/mm2 for 85% of time

ii) 500 N/mm2 for 3% of time

iii) 400 N/mm2 for 12% of remaining time

Material: Plain carbon steel 50C

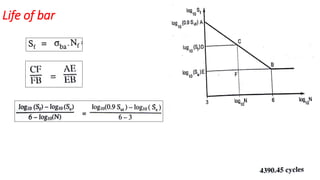

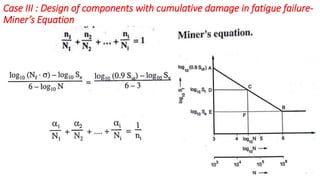

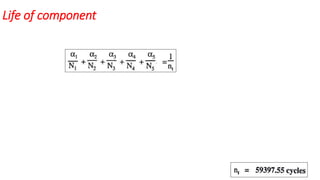

Using Miner's rule:

For stress i)

N1/Nf1 = 0.85

Where, N1 is no. of cycles component can withstand at stress 350 N/mm2

Nf1 is no. of cycles to failure at stress 350 N/mm2

Similarly, for other stresses:

N2/Nf2 = 0.03

N3/Nf3 = 0.12

Equ

![Unit 3

Design against fluctuating load

Prepared By

Prof. M.C. Shinde[9970160753]

Mech. Engg. Dept., JSCOE, Hadapsar](https://image.slidesharecdn.com/unit3r1-210628092728/75/Unit-3-Design-of-Fluctuating-Loads-1-2048.jpg)