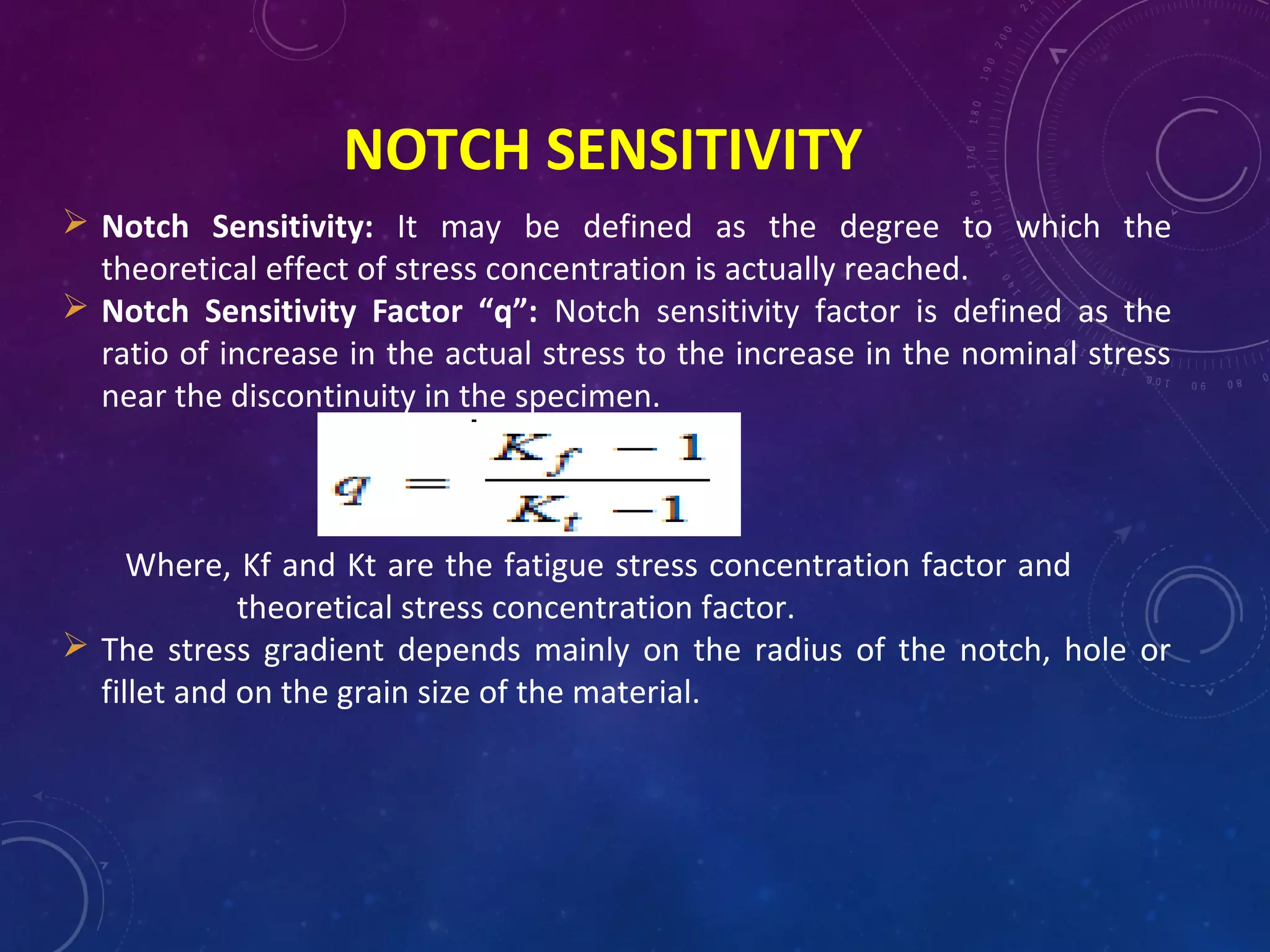

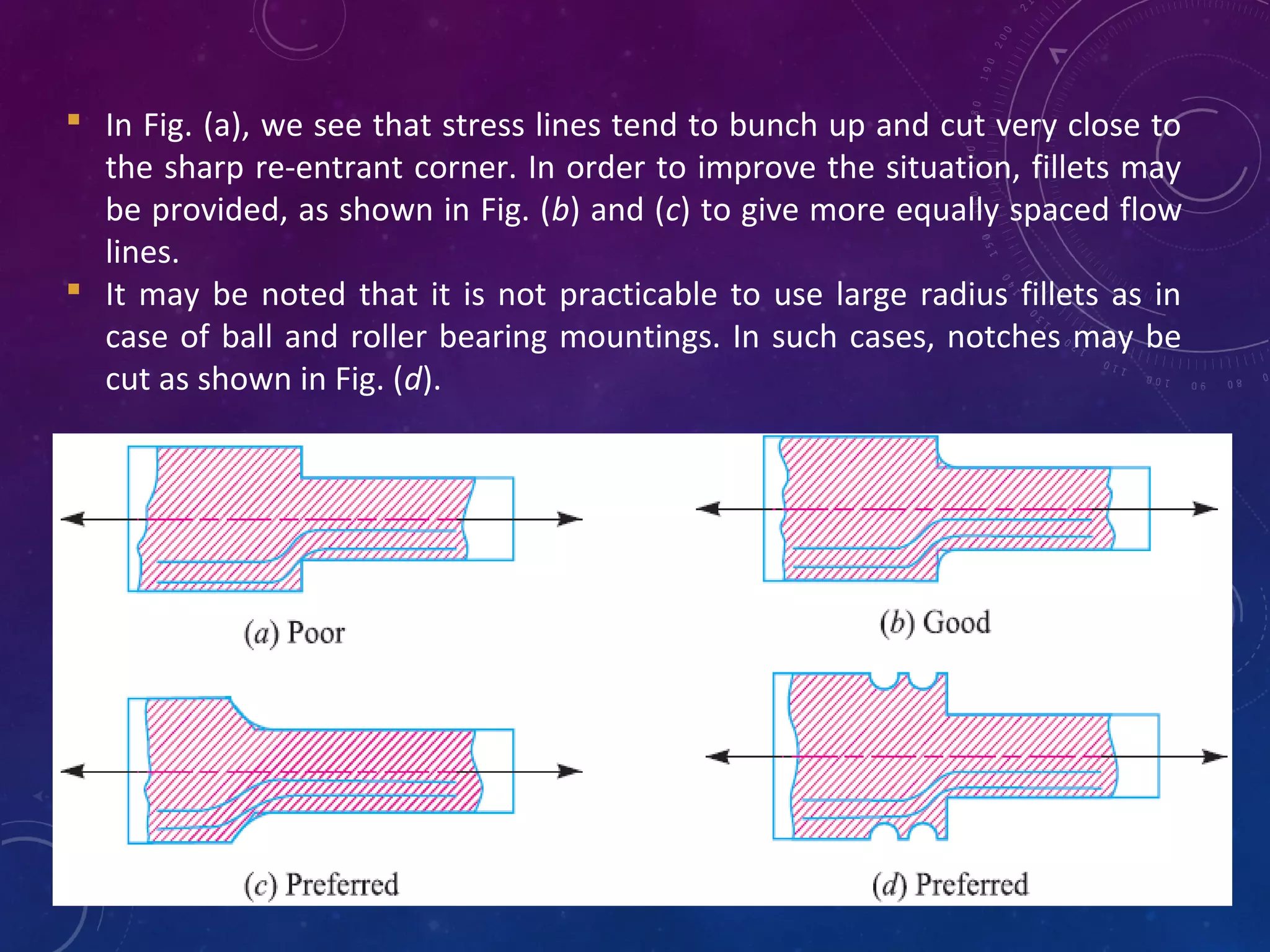

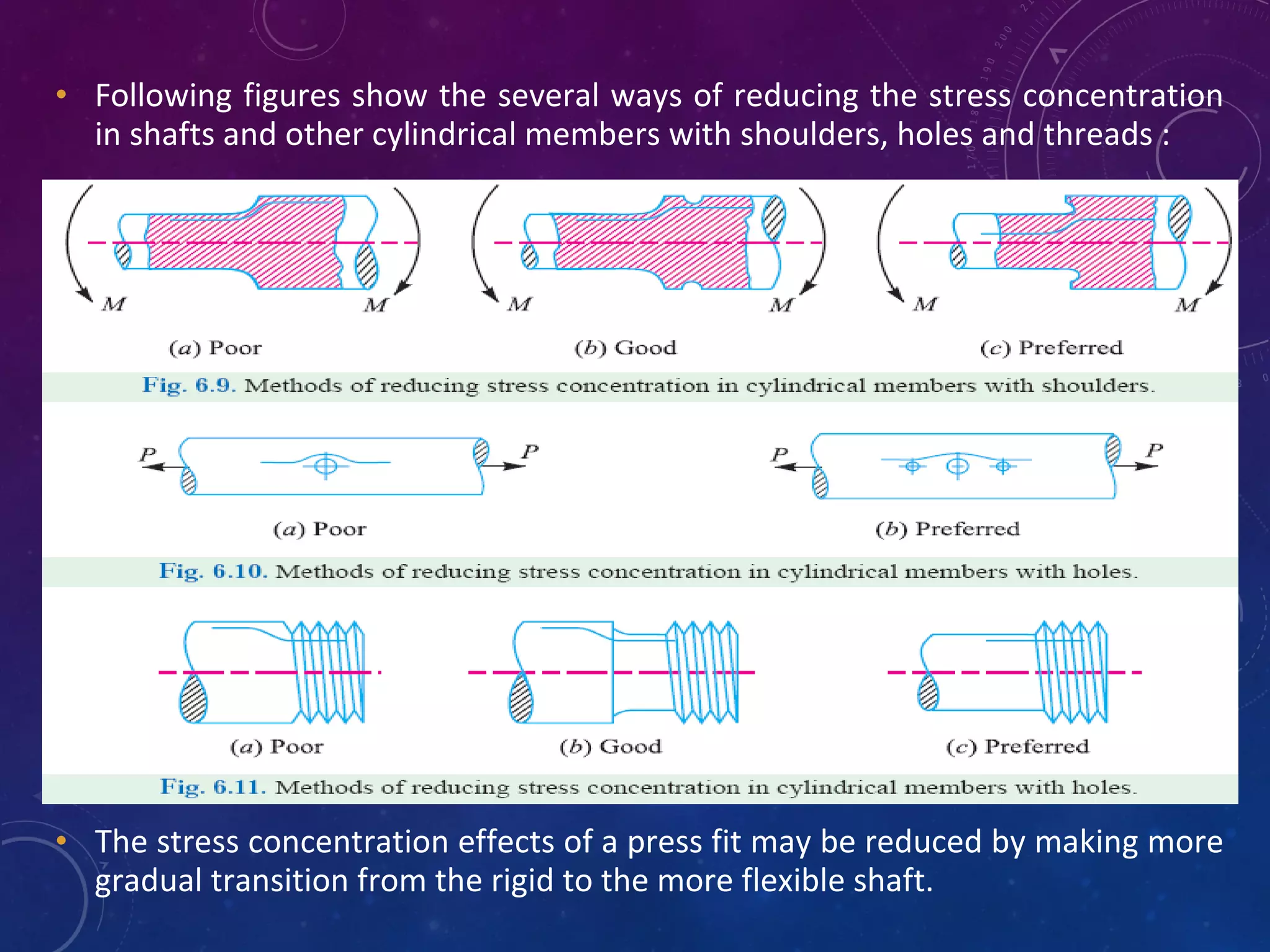

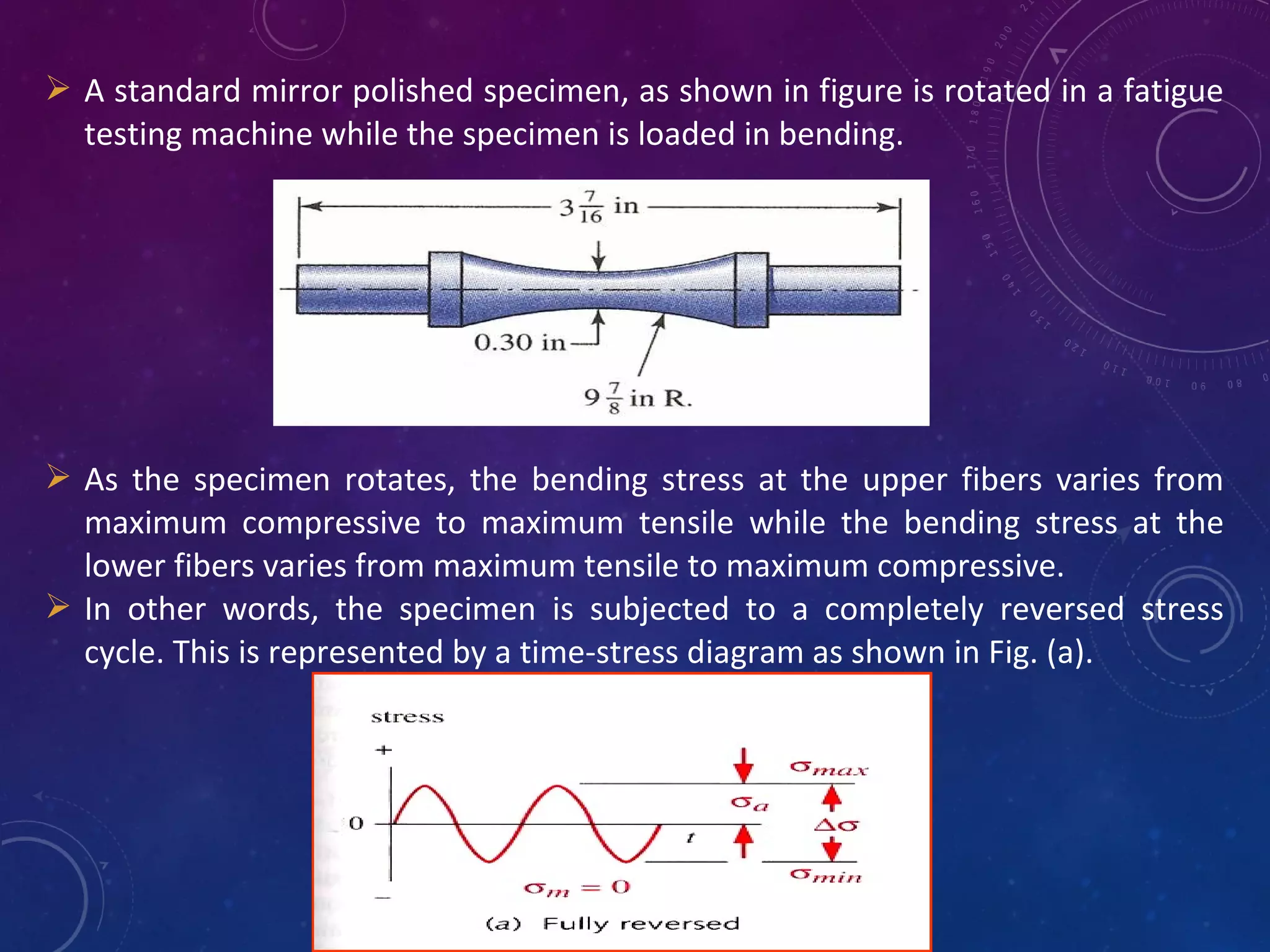

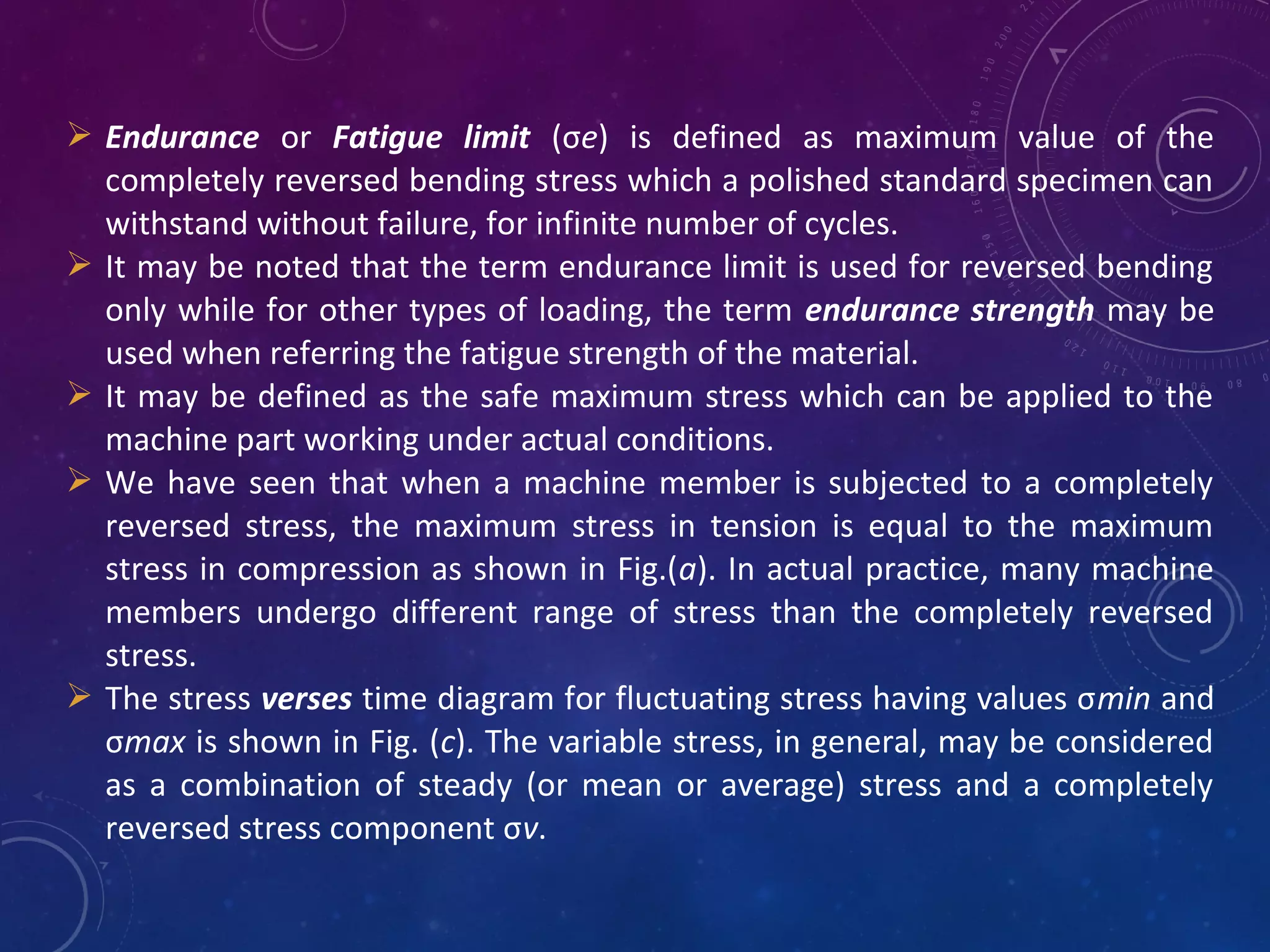

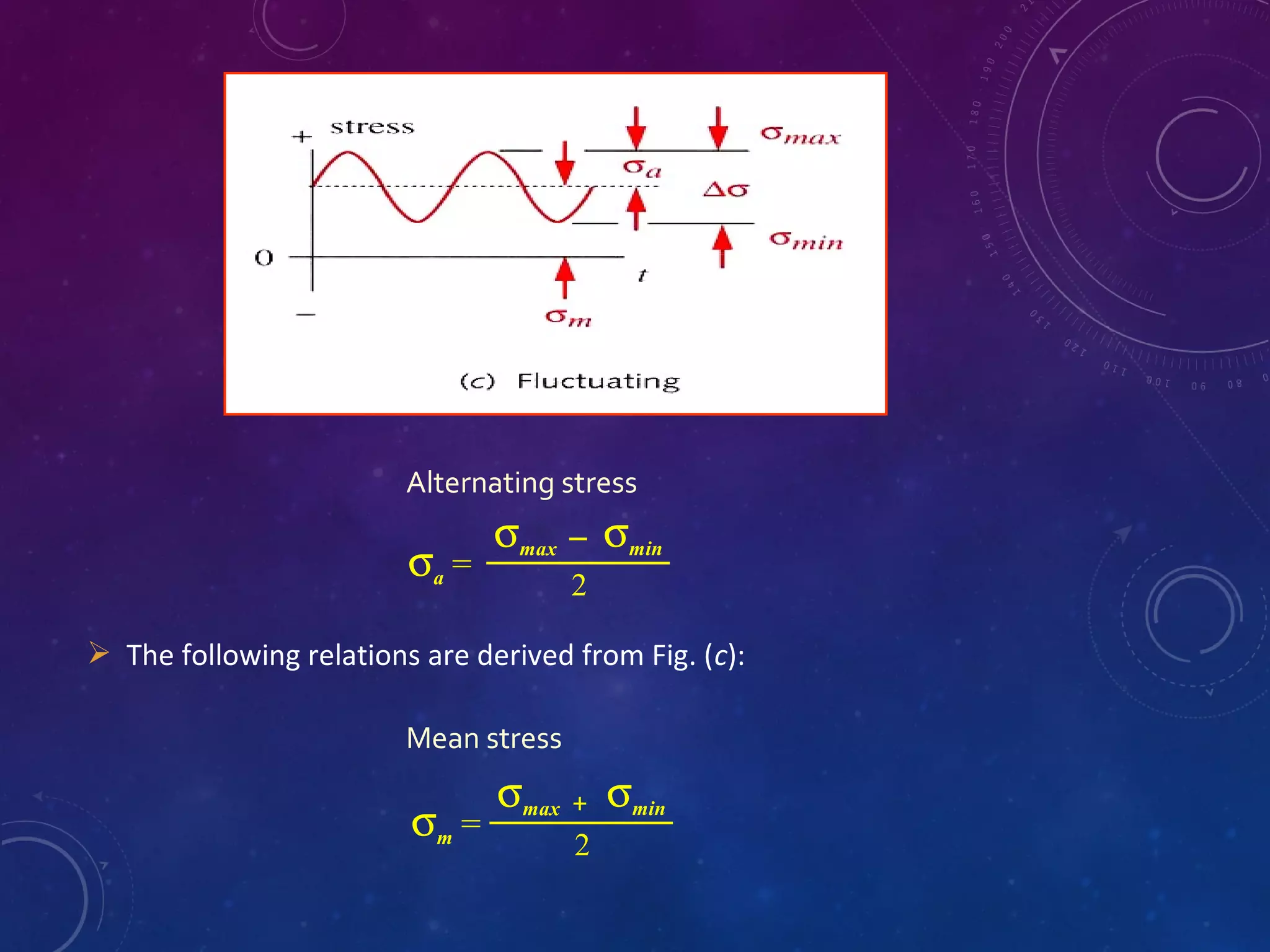

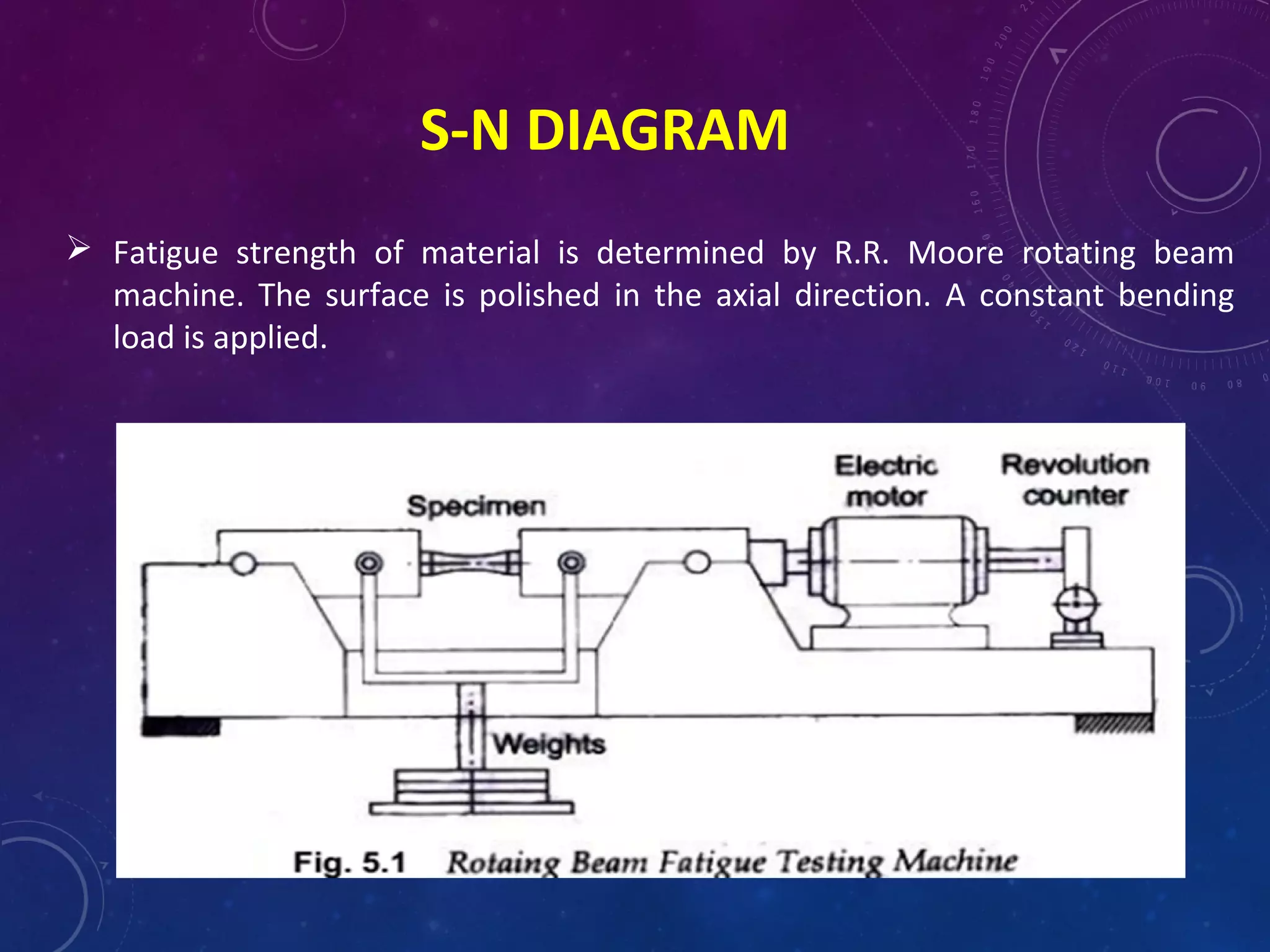

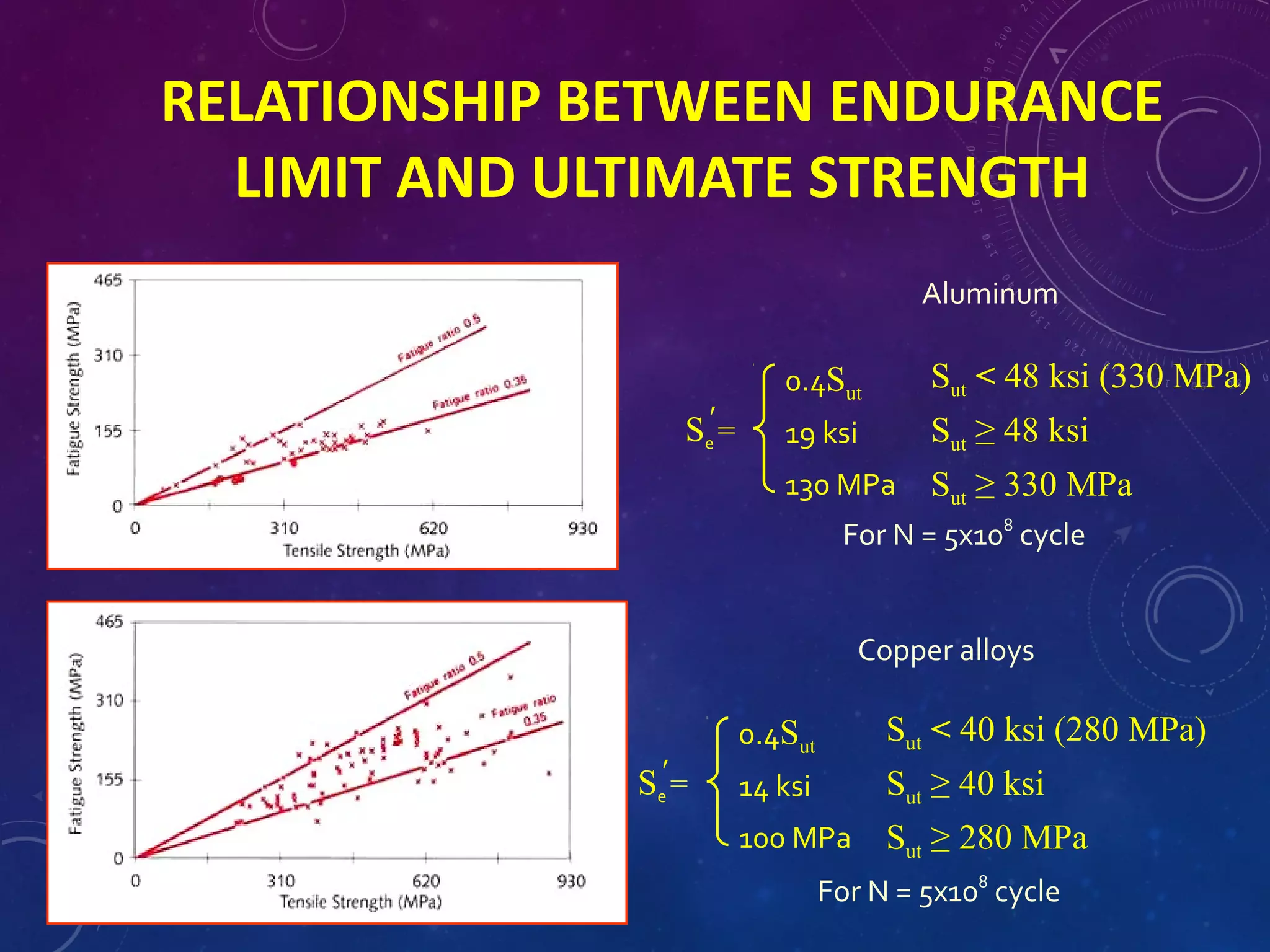

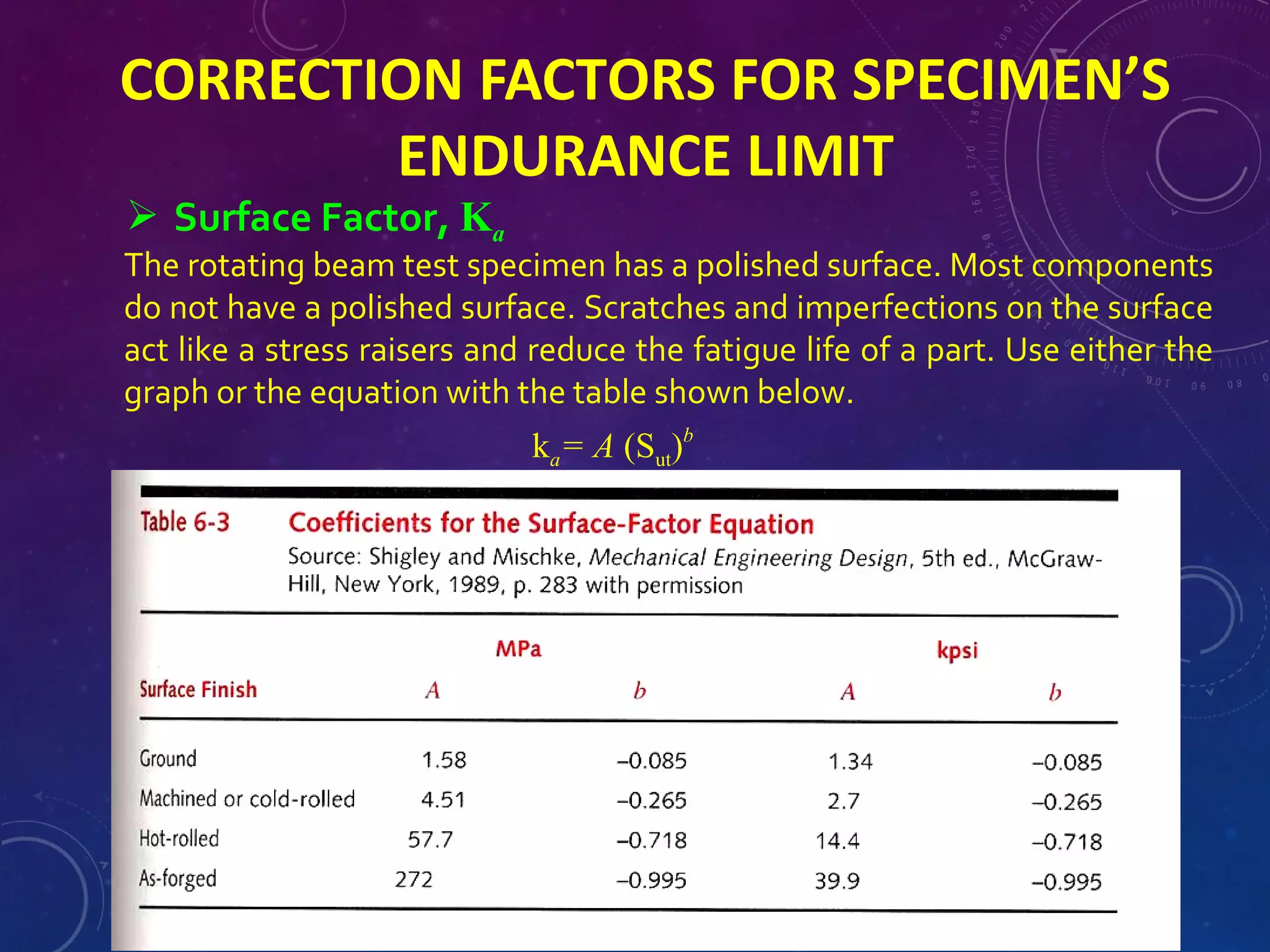

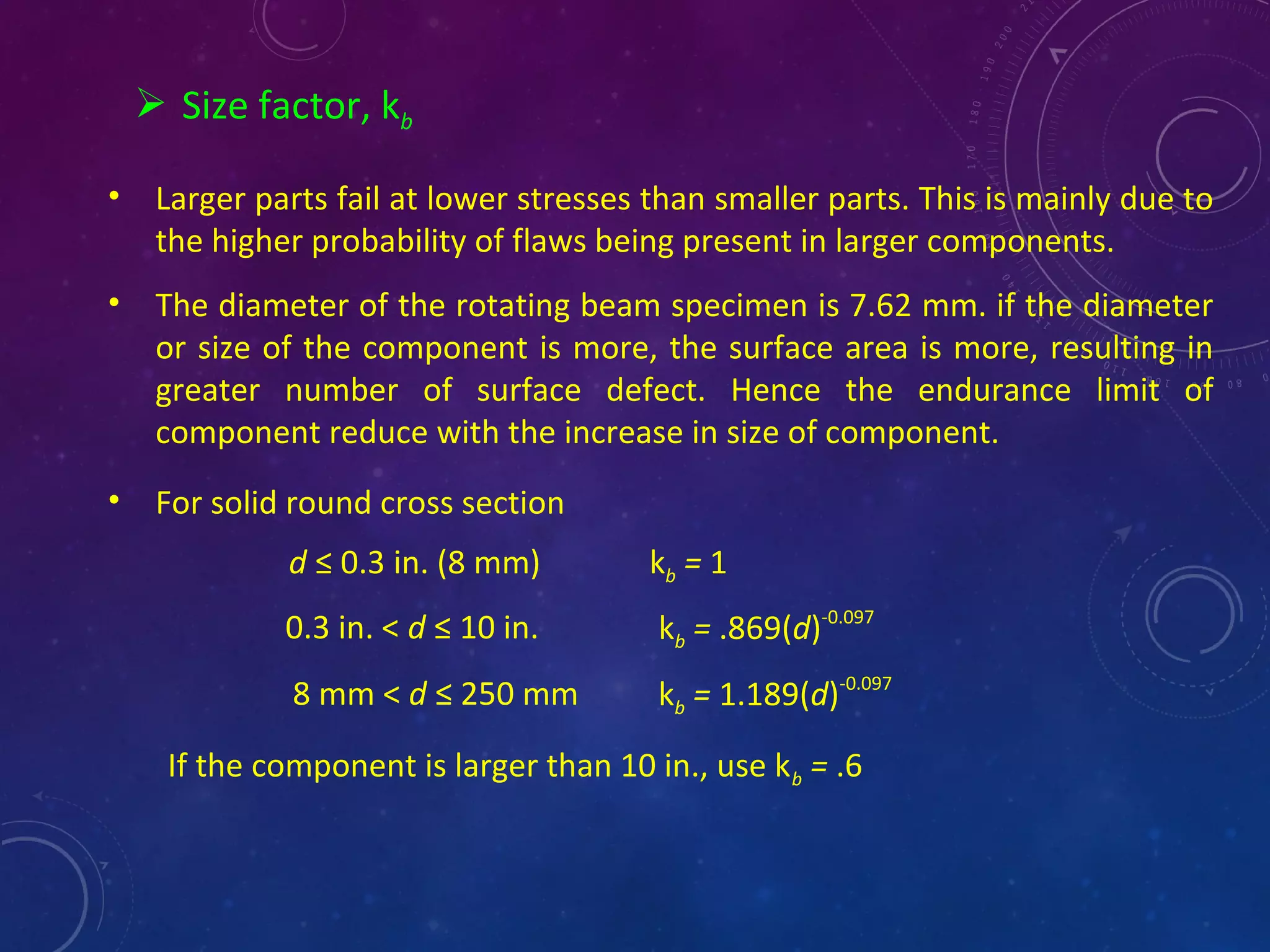

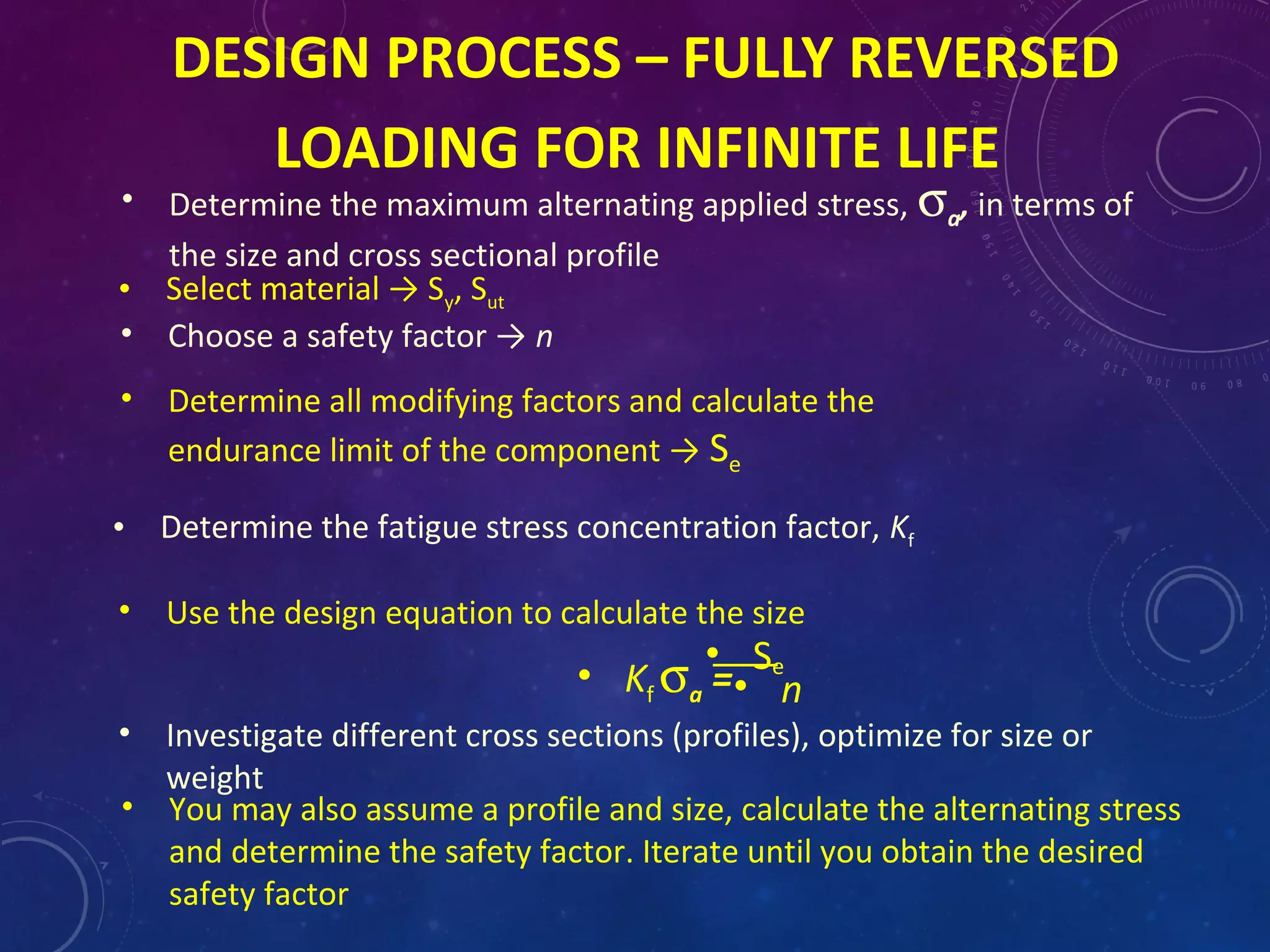

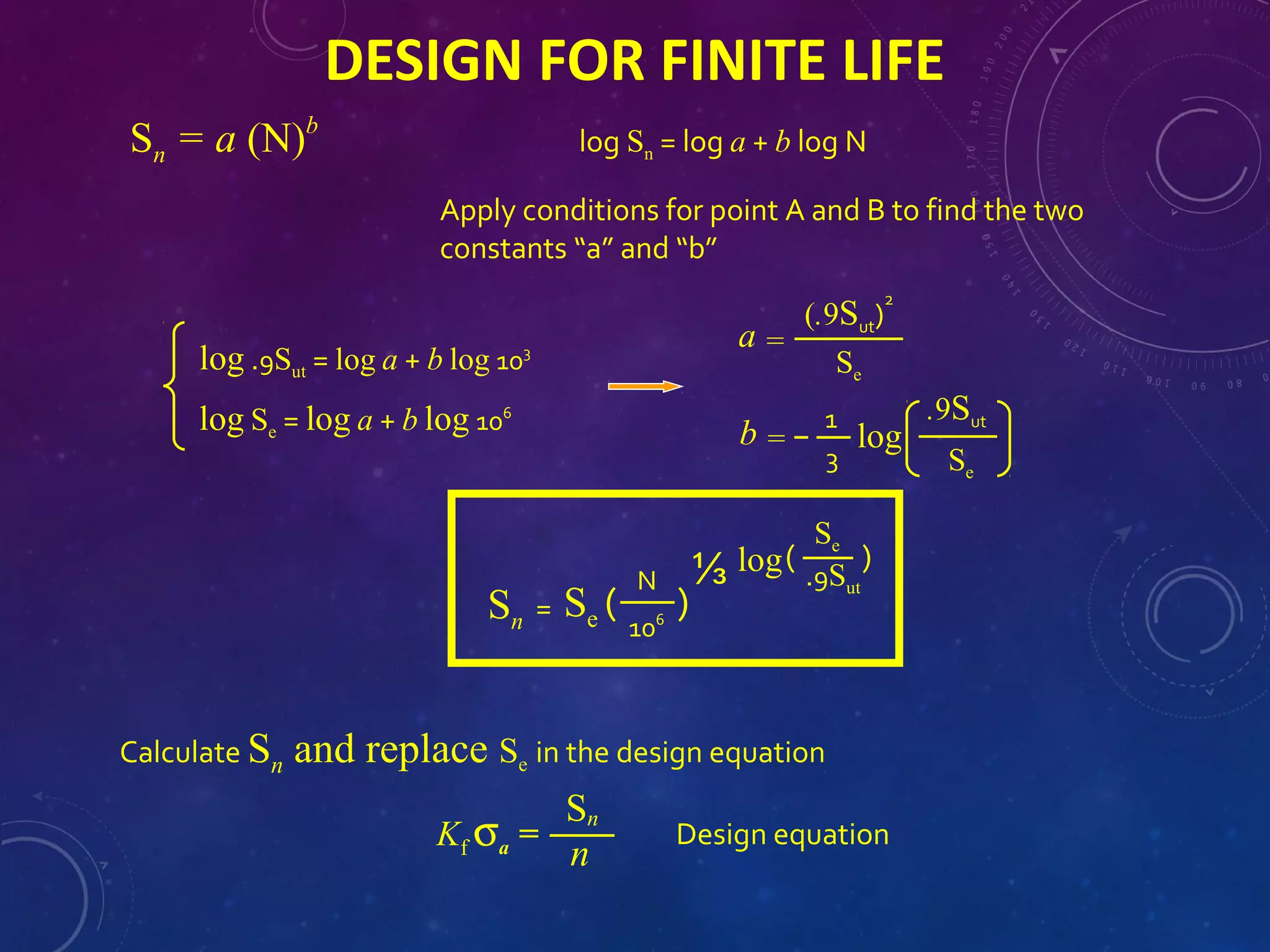

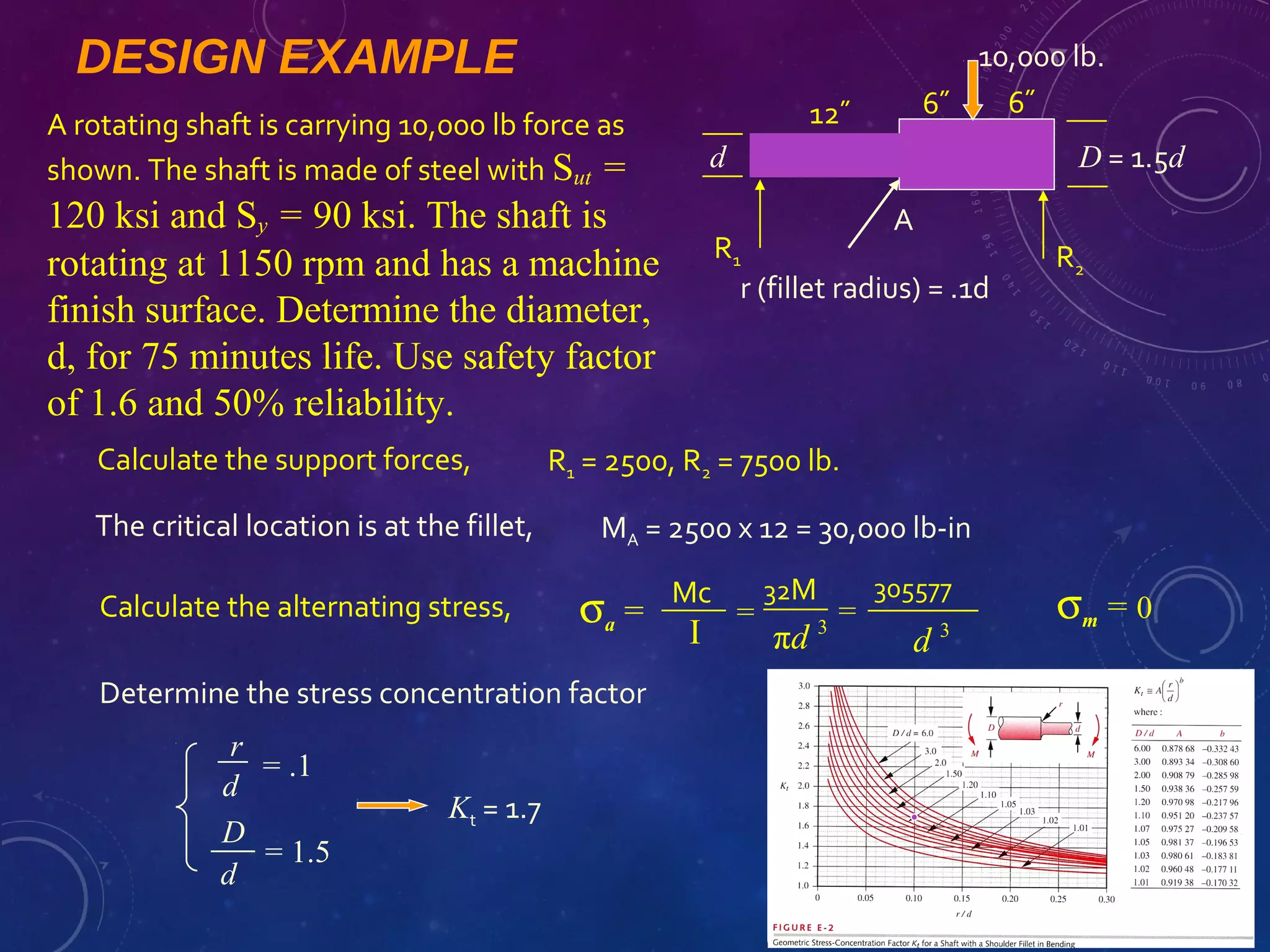

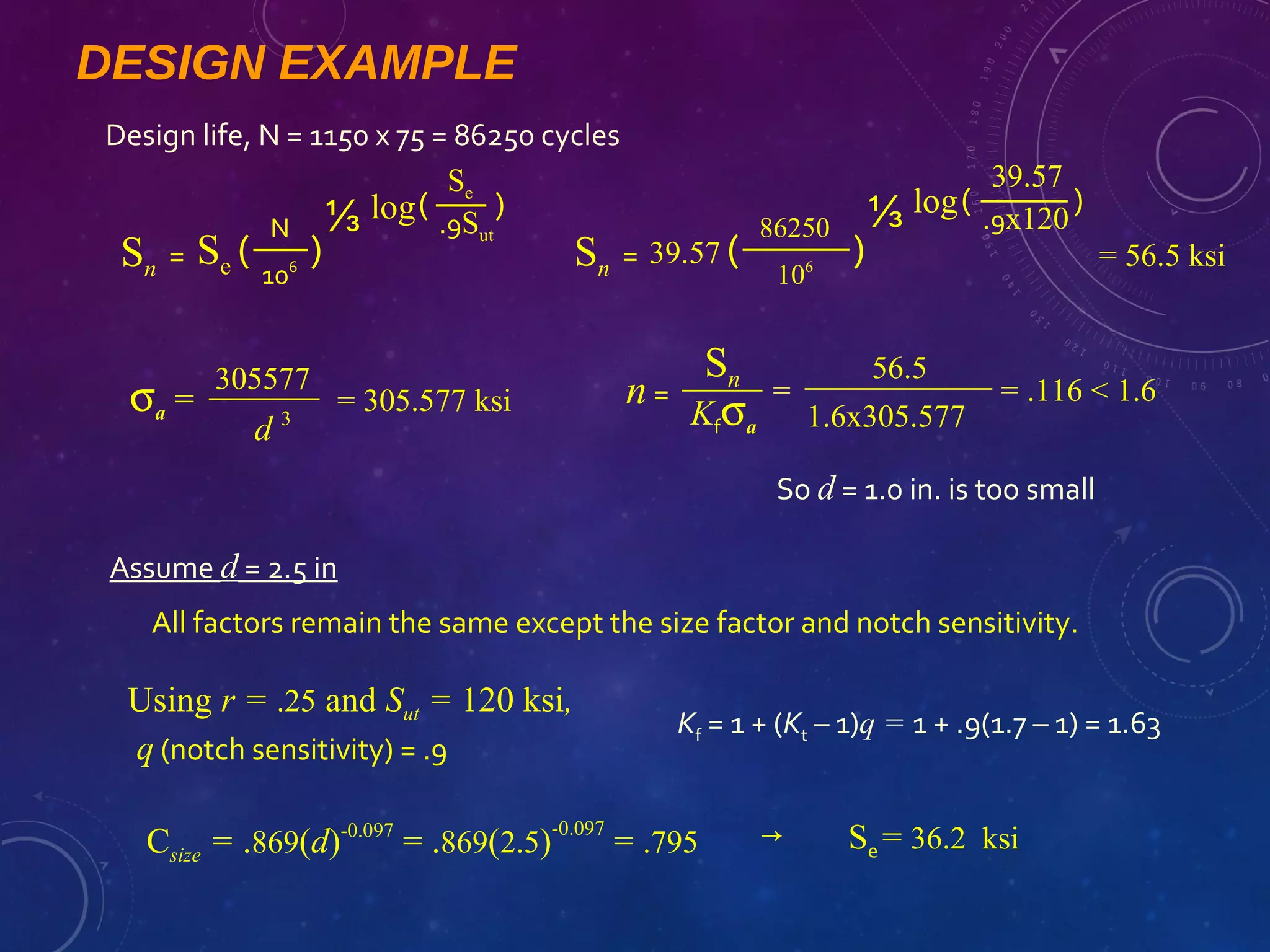

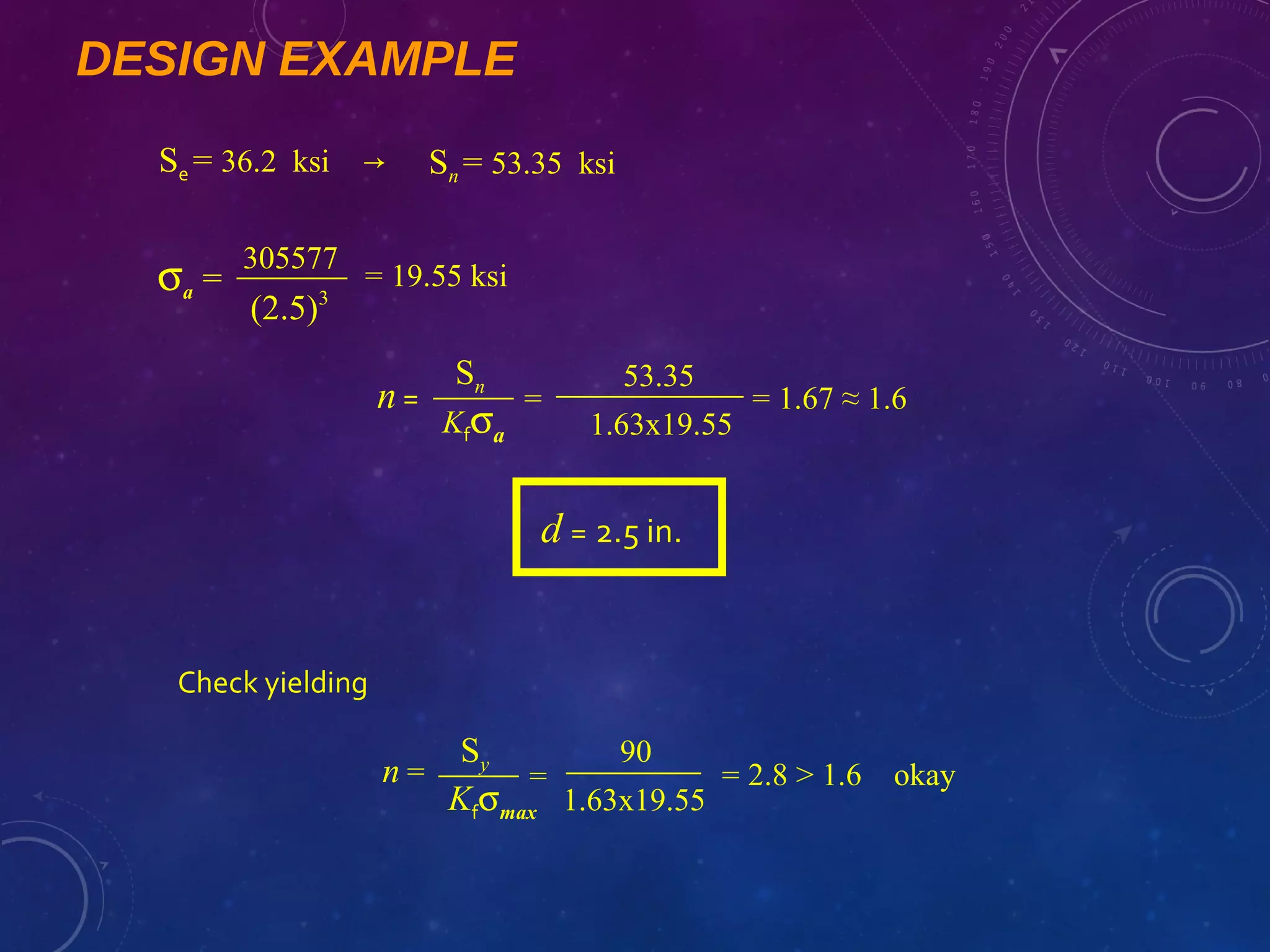

The document discusses stress concentration and fatigue failure in machine elements. It defines stress concentration as irregular stress distribution caused by abrupt changes in cross-section shape. Stress concentration factors are introduced to quantify the maximum stress compared to nominal stress. The document also discusses endurance limit and fatigue strength testing methods. Factors that affect fatigue strength like material properties, surface finish, size and temperature are summarized. Methods to evaluate and reduce stress concentration in designs are provided.