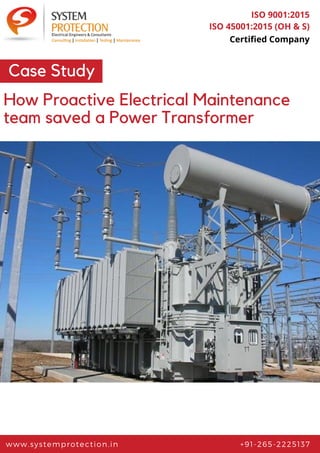

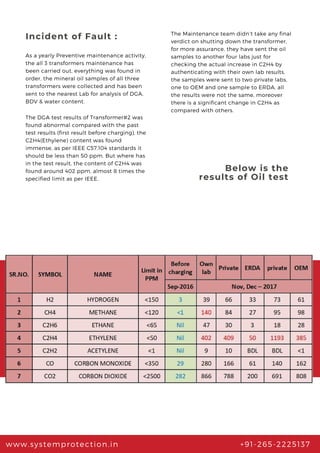

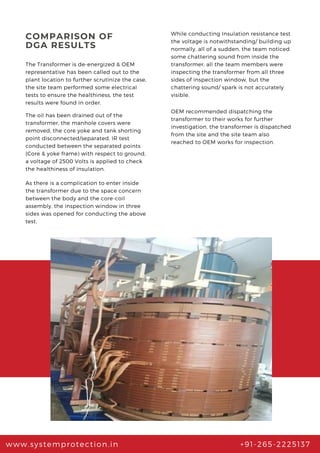

This case study describes how proactive maintenance practices saved a power transformer. During routine maintenance, oil samples from three identical transformers were tested. One transformer's (Transformer #2) test results showed abnormally high ethylene levels, over 8 times the limit. Upon further inspection of Transformer #2 after de-energizing it, a washer was found resting on the core, causing sparking during insulation resistance testing. Removing the washer resolved the issue. The conclusion recommends carefully checking for foreign objects before commissioning transformers and conducting regular diagnostic tests to detect problems early.