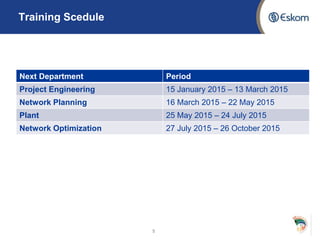

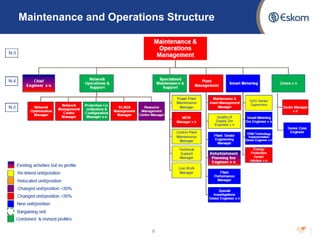

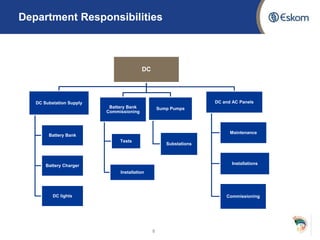

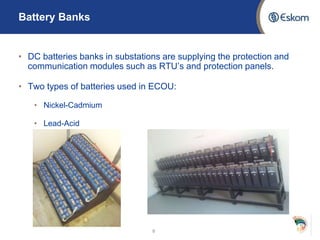

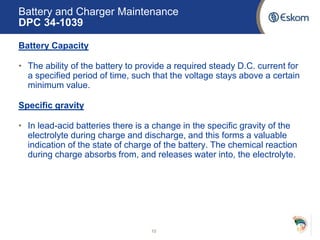

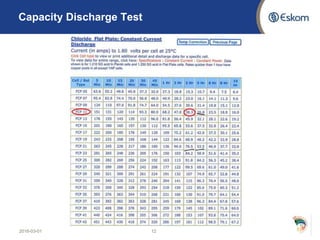

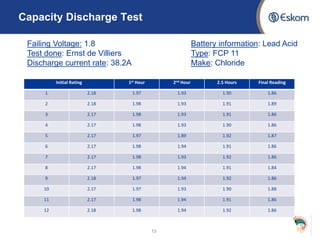

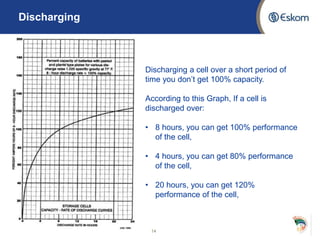

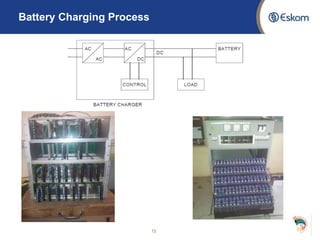

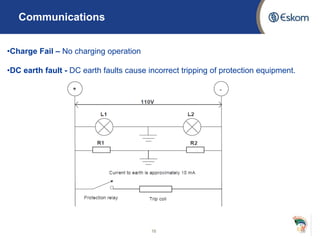

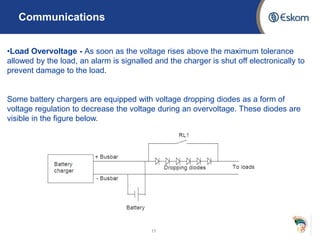

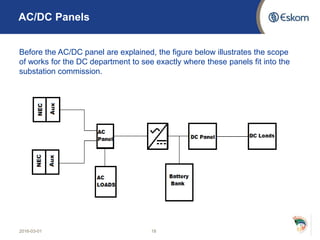

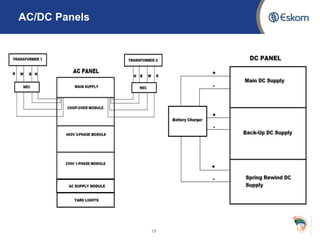

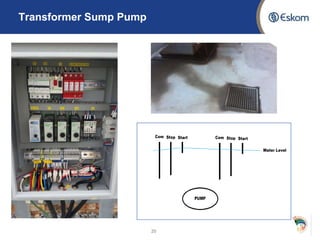

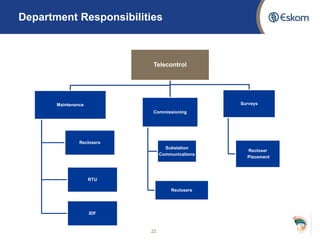

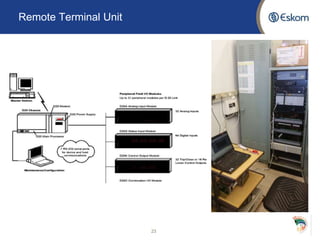

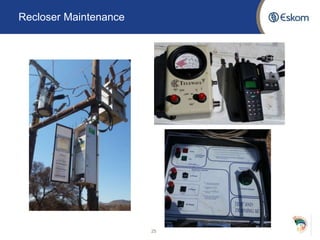

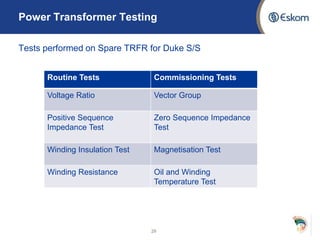

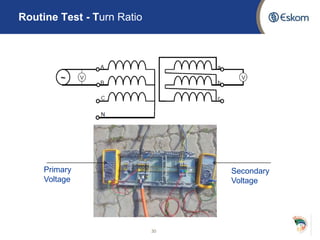

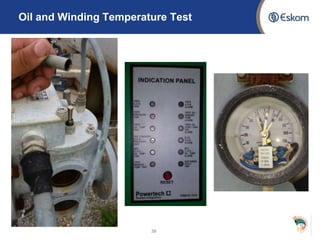

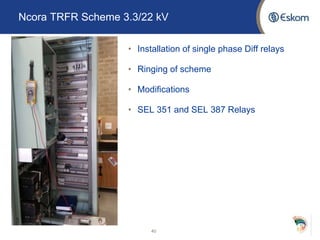

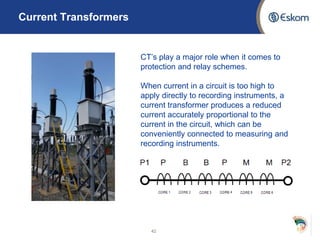

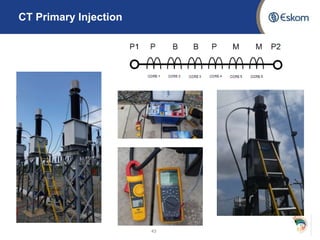

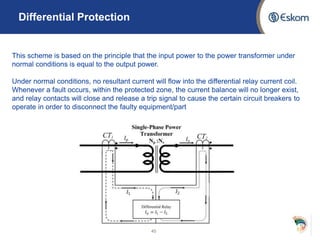

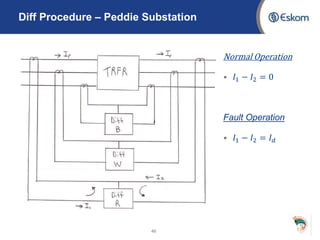

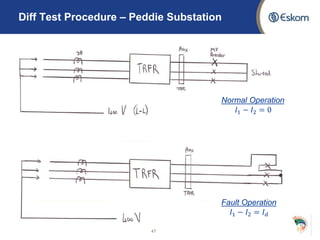

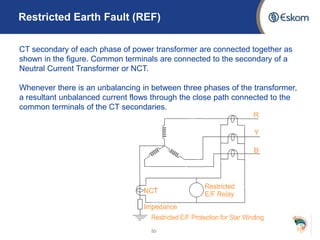

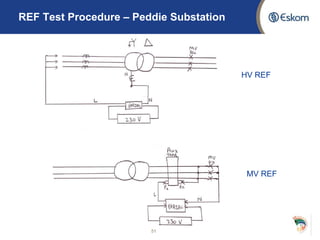

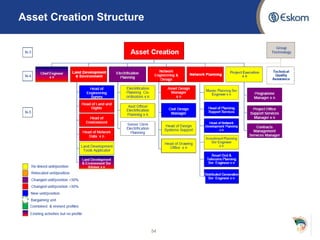

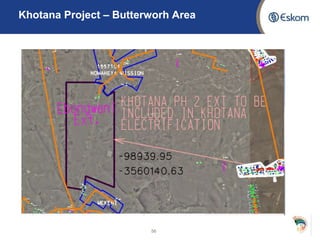

The document provides a summary of Ernst de Villiers' training at Eskom over a 6-month period from July 2014 to January 2015. It describes the various departments visited, including Control Plant Maintenance (CPM) covering DC, telecontrol, and protection systems, as well as Network Engineering Design. Specific training content for each department is outlined, with examples of battery testing and commissioning procedures, recloser maintenance, protection relay testing, and preliminary design work for the Khotana electrification project.