This document provides an introduction to boiler control systems engineering. It begins with an overview of basic boiler components such as the furnace, fans, heat exchangers, drums and piping. It then discusses common control strategies for boilers like feedback control, feedforward control and cascade control. The document provides details on tuning PID controllers and determining control parameters. It is intended to help anyone working with boiler control systems understand the engineering of boiler controls.

![h(1) < h(2) BECAUSE t(1) < t(2)

t =WATER TEMPERATURE

h =HEIGHT OF WATER COLUMN

MIRRO~---· OPERATOR

Figure 4-5 Gage glass drum level indication.

STEAM

h(1)

WATER

h(2)

h (1), h (2), h (3)-

70° WATER COLUMN EQUIVALENT

NET TRANSMITTER PRESSURE DIFFERENTIAL

= h (3)- [h (1) + h(2)]

Figure 4-6 Drum level transmitter.

Feedwater 35

t(2)

WATER

CONDENSATE RESERVOIR

Th(3)

1

TRANSMITTER

Figure 4-6 is a typical arrangement ofa differential drum level measuring transmitter.The dif-

ferential transmitter output signal increases as the differential pressure decreases. (Note the

differential pressure connections.) The differential pressure range will vary between 15 and 30](https://image.slidesharecdn.com/boilercontrolsystemengineering-190127214007/85/Boiler-control-system-engineering-54-320.jpg)

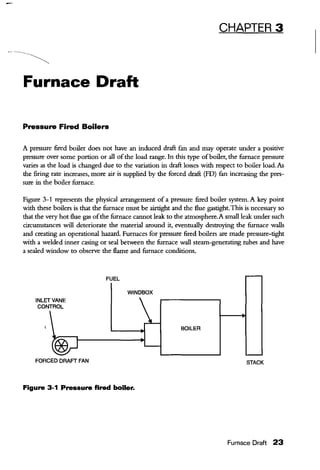

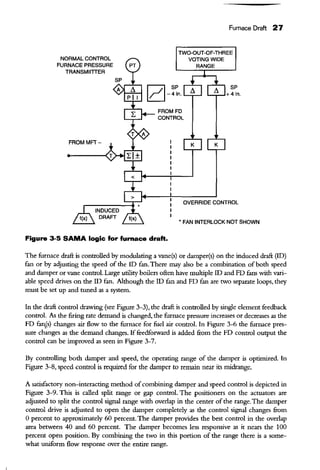

![88 Boiler Control Systems Engineering

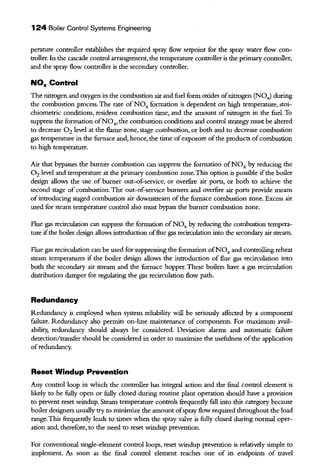

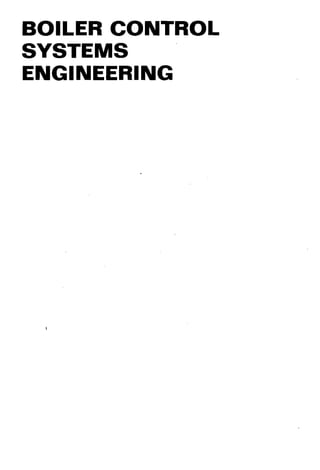

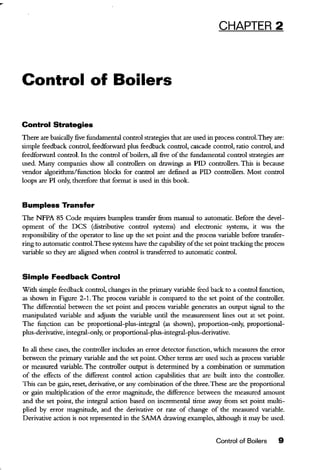

Figure 8-2 is a multiple burner boiler iuterlock system diagram.

~~~~~~~~~~~~~=~J~=R~l::::::=jCioseindivk:lualigniter I

safety shutoff valve(s)

Typical cause of trip indication 1and de-energize sparks

Igniter I______"T___,~~~~~~~~~~fuel ~ Igniter fuel trip tor Class 1 Igas _ 1Igniters, block 11

-T- ~

~~~~~~~~~~~~~~~~i=i~~ Close Igniter header

Igniter '---~ and Individual igniter

fuel __..., safety shutoff valve(s)

trip -----+---' and de-energizer sparks

logic

~

Q

G)JLossofiDfan(s)

8JLossofFDfan(s)

0 ]combustion airflow tow

0 ]High furnace pressure

0 ]Loss of all flame

0 [Partial loss of flame, introducing hazard

0 ]All fuel inputs shut off

e ]Manual trip switch

@ [tgniter fuel trip (Class 1 igniters)

S Jtgniterfuel trip (Class 1 igniters)

Q

Q

Q

Q

Master

'"''trip ~L......

logiC I r-""""

-

Master

'""'trip

relay(s)

Q JII-+Q '--

'-;:~

rr;·It~

Q~fuel Close main gas safety

trip f-.L-:--7-:-------+-...j shutoff valve(s) and

r+- logic ~ individual burner

_Q1 ...._____ safety shutoff valves

@ 1'~~~~~·~o~o~ll~b~om~o~cp~c~~~"~"'~~~;~~~=9~~~"~011J===- Closemainoilsafety

fuol f--..L-7-:--------:--...j shutoff valve(s) and

Q 1, trip ~ .__________._ individual bumer~

1

Atomizing medium pressure Improper --------..--

'___s"2.l:fclog~<~--- safety shutoff valves

Q IAll coal-firing equipment stopped or tripped ~ Y · Coal - I Stop coal flow I~ !or common coal-firing equipment tripped '----'--'--------~---lo-1 'to pulverizers

fuel r and burners

a I!loss of individual gas or oil burner I~ flame with one or more additional

stable burner flames present

@ ILoss of main coal burner flame

Q

trip

logic

Close individual burner safety shutoff valve(s)

and Individual igniter safety shutoff valve{s)

and de-energize associated sparks

Follow tripping strategy in 6,8,4

Figure 8-2 Interlock system for multiple burner boiler.

I

I](https://image.slidesharecdn.com/boilercontrolsystemengineering-190127214007/85/Boiler-control-system-engineering-107-320.jpg)