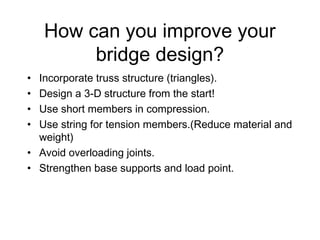

This document outlines the goals, constraints, materials, testing procedures, and engineering fundamentals for a student bridge design project. The goals are for students to learn the design process, practical applications of concepts like trigonometry and statics, and improve skills like prototyping, testing, and technical communication. Students will design and build bridges using tongue depressors and glue that can support at least 15 pounds using no more than 100 tongue depressors. Bridges will be tested and scored based on their load capacity divided by weight. The project involves component testing, prototyping, redesign, and a final competition. Guidance is provided on truss designs, mechanics of materials concepts, and construction hints.