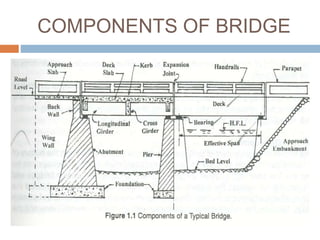

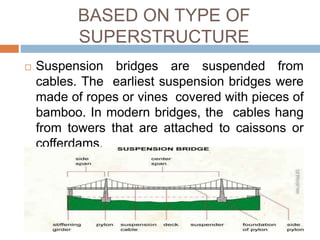

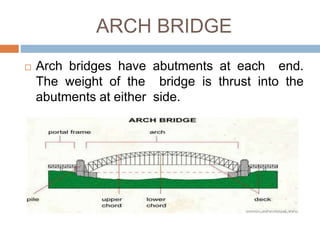

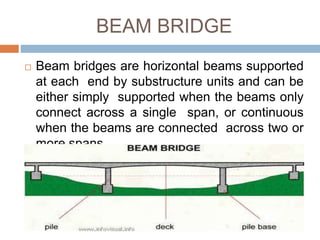

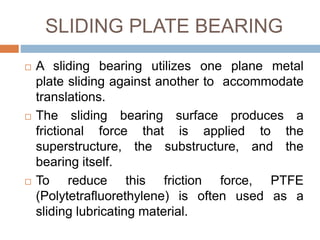

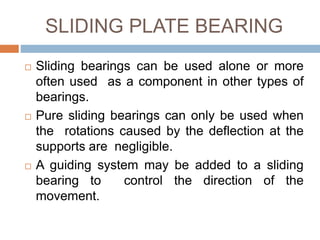

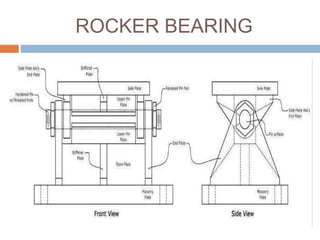

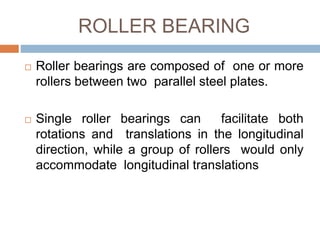

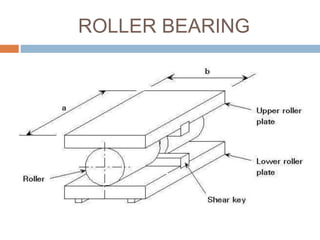

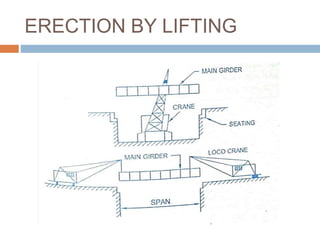

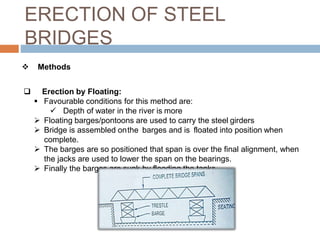

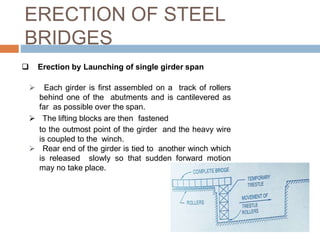

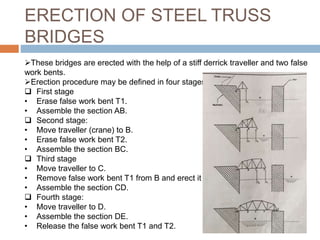

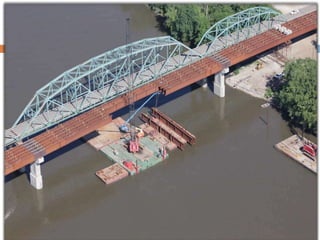

The document discusses the various aspects of bridge construction, including site selection factors, investigation stages, and classification of bridges based on different criteria. It details the construction methods for steel girder and truss bridges, emphasizing the importance of proper planning, material usage, and the roles of various components like bearings. Additionally, it explains the techniques involved in erecting different types of bridges, such as suspension and beam bridges.